EPDM EP70BU15 O-Ring, Size: -014

Material: EPDM EP70BU15 O-Ring

Size: AS568 -014 O-Ring

Part Number: EP70BU15-OR-014

EP70BU15

EPDM (EPR, EPM)

70

Shore A

X-Ray Detectable

FDA Compliant

3A Sanitary

Metal Detectable

Peroxide Cured

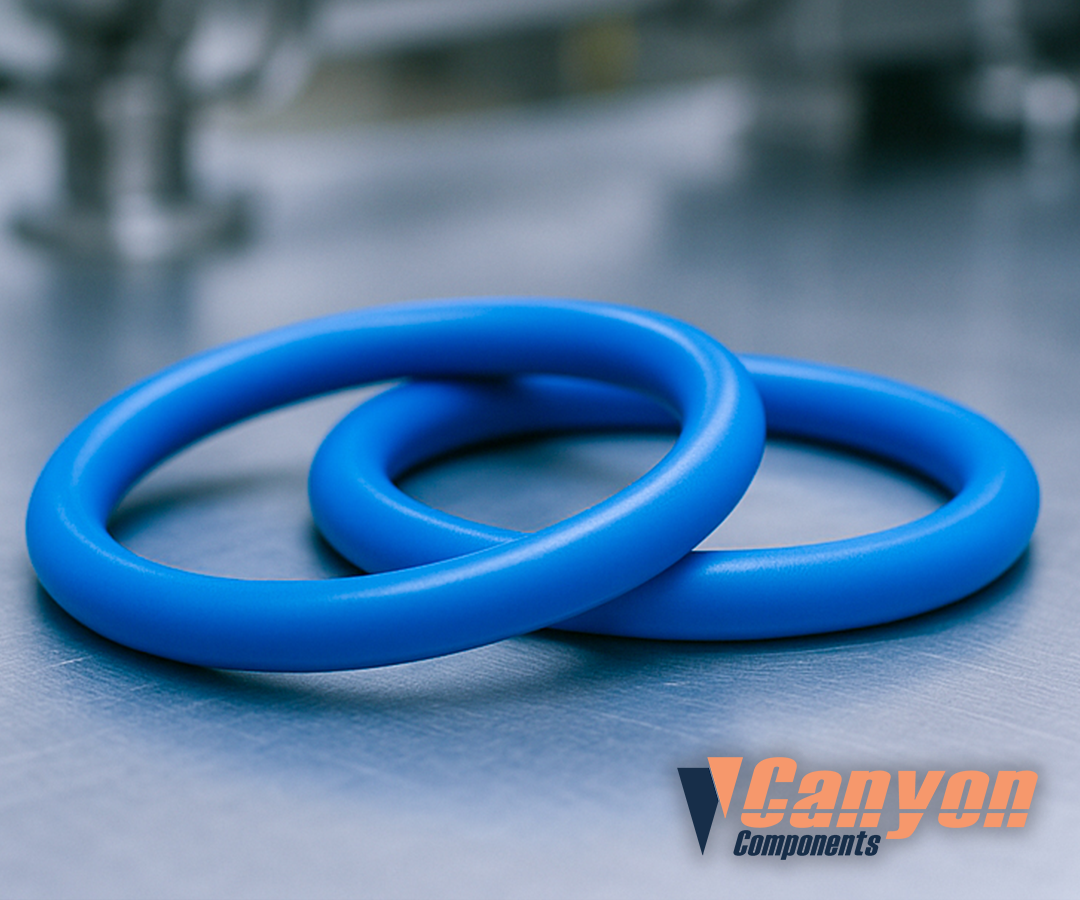

Color: Blue

Detailed Description

EP70BU15-OR-014 is a Blue, 70 Shore A, Peroxide Cured EPDM (EPR, EPM) O-Ring. EP70BU15 is manufactured with the following features & specifications: X-Ray Detectable, FDA Compliant, 3A Sanitary, Metal Detectable. EP70BU15-OR-014 is AS568 size -014 O-Ring also referred to as 1.78mm (Cross Sectional Diameter (CS)) x 12.42mm (Inside Diameter (ID)).

Material: EPDM EP70BU15 O-Ring

Size: AS568 -014, 1.78mm CS X 12.42mm ID (0.070" CS X 0.489" ID)

| Technical Specification | Value |

|---|---|

| Compound Number | EP70BU15 |

| Material | EPDM (EPR, EPM) |

| Cure | Peroxide Cured |

| Color | Blue |

| Durometer | 70 Shore A |

| High Temperature | 150 °C / 302 °F |

| Low Temperature | -55 °C / -67 °F |

| Geometry Specifications | |

| Cross Sectional Geometry | O-Ring |

| Size Standard | AS568 |

| Size | -014 |

| Cross Section (CS) | 1.78 mm / 0.070 in |

| Inside Diameter (ID) | 12.42 mm / 0.489 in |

| Other Specifications | |

X-Ray Detectable | |

FDA Compliant | |

3A Sanitary | |

Metal Detectable | |

EP70BU15 is Canyon’s FDA compliant, 3A sanitary, metal detectable and X-ray detectable 70 Shore A peroxide-cured EPDM designed for hygienic O-rings and gaskets used in food and dairy manufacturing environments. This blue EPDM compound provides excellent resistance to weathering and aging while maintaining low compression set for reliable long-term sealing performance. With a service temperature range of -57°C to 150°C (-70°F to 300°F), EP70BU15 performs well in CIP and SIP conditions commonly found in sanitary processing equipment. Its metal and X-ray detectability helps support foreign material control programs and food safety compliance in critical production areas.

EP70BU15 meets ASTM D2000 requirements and is well suited for use in pumps, valves, fittings, and processing equipment where regulatory compliance and detectability are required. The peroxide-cured formulation enhances thermal stability and durability compared to sulfur-cured EPDM materials. This compound is commonly selected for applications where traceability, inspection capability, and cost-effective sealing are all important design considerations. Canyon Components offers EP70BU15 as a dependable solution for sanitary EPDM O-rings and gaskets in regulated food and dairy applications.

Common relevant keywords:

FDA compliant EPDM, metal detectable O-rings, X-ray detectable gaskets, 3A sanitary elastomer seals, food grade EPDM rubber, dairy processing O-rings, blue EPDM sealing material, peroxide cured EPDM, sanitary valve and pump gaskets, hygienic sealing solutions, Datasheet, TDS, Test Report, MTR, MSDS, SDS