ISO 9001 Certification

ISO 9001 is a globally recognized standard for quality management systems (QMS). It sets forth a framework for consistent performance, reliable service, and continuous improvement, ensuring that businesses like ours not only meet but exceed customer expectations in every aspect of operation. By aligning our processes with the rigorous criteria of ISO 9001, we demonstrate our unwavering dedication to excellence in every product we deliver and every service we provide.

As a leader in our industry, we proudly uphold the highest standards of quality and efficiency, a commitment encapsulated in our achievement of ISO 9001 certification.

If you have any questions, please feel free to reach out to our expert staff for assistance!

Back to Reference Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

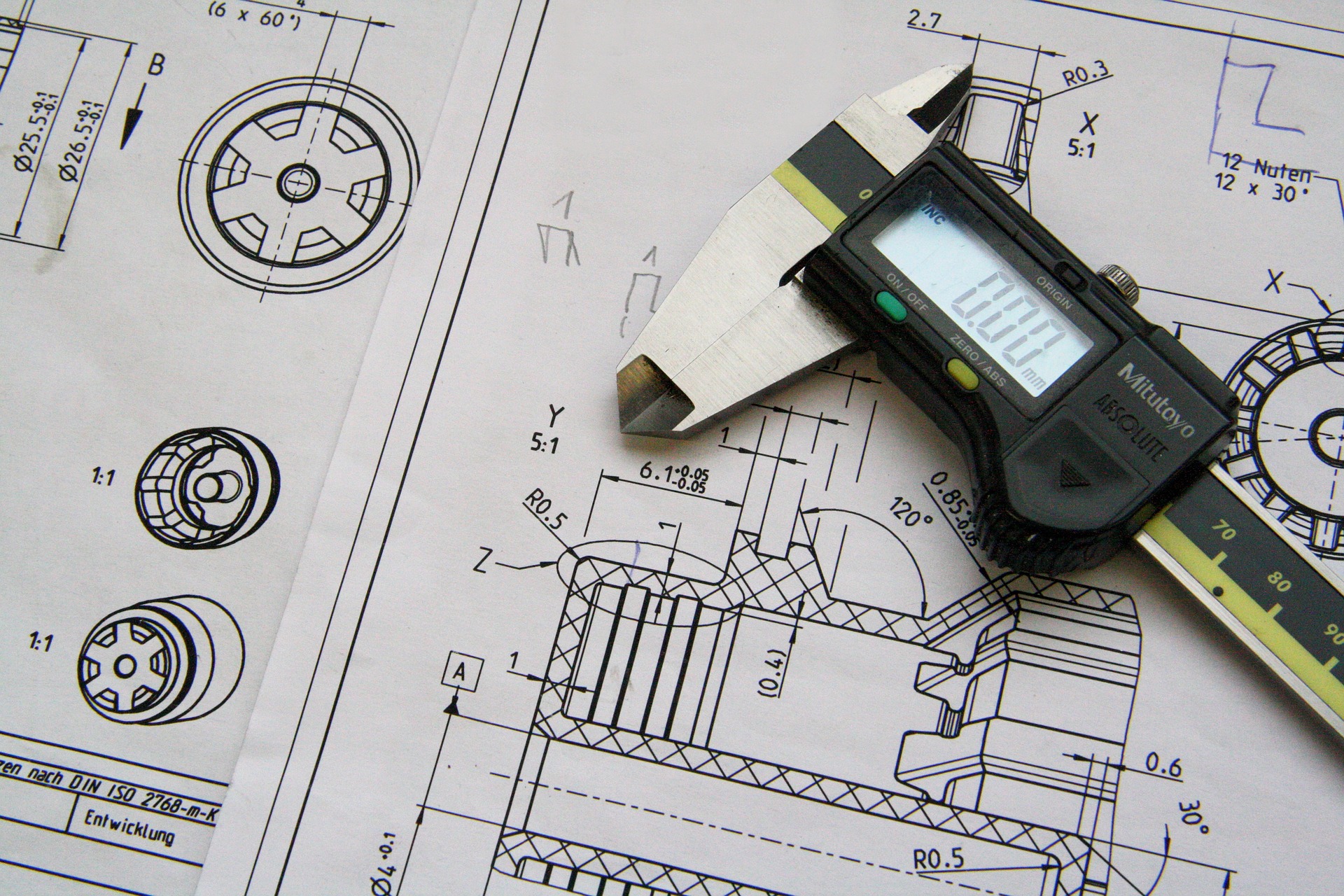

Quality assurance is critical in every industry where reliability and precision determine performance. Canyon Components’ ISO 9001 certification demonstrates our commitment to manufacturing excellence, process control, and continuous improvement. Every O-ring, gasket, seal, and custom part we produce undergoes strict quality management procedures that ensure consistency, traceability, and compliance with international standards. Our products, available in Kalrez®, Canrez®, Chemraz®, Parker®, FFKM, FKM, EPDM, silicone, and NBR materials, are trusted by aerospace, medical, chemical, and industrial manufacturers that depend on flawless sealing performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does ISO 9001 improve product reliability and performance?

ISO 9001 certification requires continuous process monitoring, corrective action systems, and quality audits that maintain high standards across all production operations. At Canyon Components, each batch of materials is verified for composition and performance before molding or machining. In-process inspections, dimensional checks, and post-curing tests ensure parts meet exact specifications. Our documentation and training programs guarantee that the same rigorous standards apply across orders. The result is consistent sealing reliability and long-term performance across all product lines. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are Canyon Components’ ISO 9001 certified products suitable for critical applications?

Yes. Our ISO 9001 certified production system supports industries where quality cannot be compromised, including aerospace, medical device manufacturing, chemical processing, oil and gas, and semiconductor fabrication. These sectors rely on our materials for resistance to heat, pressure, and aggressive chemicals, and they require verification of every production variable. Canyon Components’ quality program ensures that each part is made from verified compounds, measured against international standards, and documented for traceability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components verify material quality under ISO 9001 standards?

Material quality is verified through a series of incoming inspections and analytical tests. All compounds are sourced from approved suppliers and undergo verification for hardness, specific gravity, and cure consistency. For critical materials like FFKM, FKM, and EPDM, we also perform FTIR and compression set testing to confirm compound identity and physical performance. Each batch is assigned a lot number that links raw materials to finished goods, maintaining complete traceability. This ensures customers can rely on the integrity of every component delivered. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What testing and inspection methods are part of Canyon Components’ ISO 9001 program?

Our ISO 9001 system includes dimensional inspection, tensile and elongation testing, durometer verification, visual inspection, and pressure or leak testing where applicable. For precision components, coordinate measuring machines (CMMs) and optical comparators are used to confirm tight tolerances. Finished parts are evaluated for surface quality, flash control, and dimensional uniformity before shipment. These inspections are performed under documented quality control procedures that align with ISO 9001 standards and customer-specific requirements.

Can Canyon Components provide documentation and certification for delivered parts?

Yes. Every shipment from Canyon Components can include a Certificate of Conformance (CoC), inspection reports, and material batch traceability records upon request. For industries that require regulatory documentation, we can also provide lot-specific test data, dimensional inspection summaries, and compliance certifications that align with ASTM, AMS, or MIL specifications. Our robust documentation process supports audit readiness for customers operating under ISO, AS, or FDA quality systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does ISO 9001 certification benefit customers with ongoing supply programs?

ISO 9001 ensures that Canyon Components maintains consistent processes and documentation across recurring orders, simplifying supplier qualification for customers. Our continuous improvement initiatives, combined with controlled change management, guarantee stability in both pricing and performance over long-term contracts. For OEMs and distributors, this means seamless integration into internal quality systems and reduced administrative oversight. We also offer custom labeling, barcoding, and lot tracking to support efficient warehouse and assembly operations. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a reliable ISO 9001 certified supplier?

Canyon Components combines precision manufacturing, strict quality management, and responsive service within an ISO 9001-certified framework. Our processes are audited and continually improved to maintain consistency, documentation accuracy, and material traceability. Whether producing high-performance FFKM seals for aerospace or durable EPDM gaskets for industrial systems, every part is supplied under the same disciplined quality system. Customers trust Canyon Components for repeatable results, transparent documentation, and proven reliability, ensuring every seal and component performs exactly as intended in the field. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!