Request A Quote

We are excited to provide you with a personalized quote for your project. Please fill out the form below with as much detail as possible, and one of our representatives will get back to you with a comprehensive quote tailored to your needs.

The engineers and consultants here at Canyon Components take pride in finding the perfect seal to suit our customer’s needs.

Back to Services Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

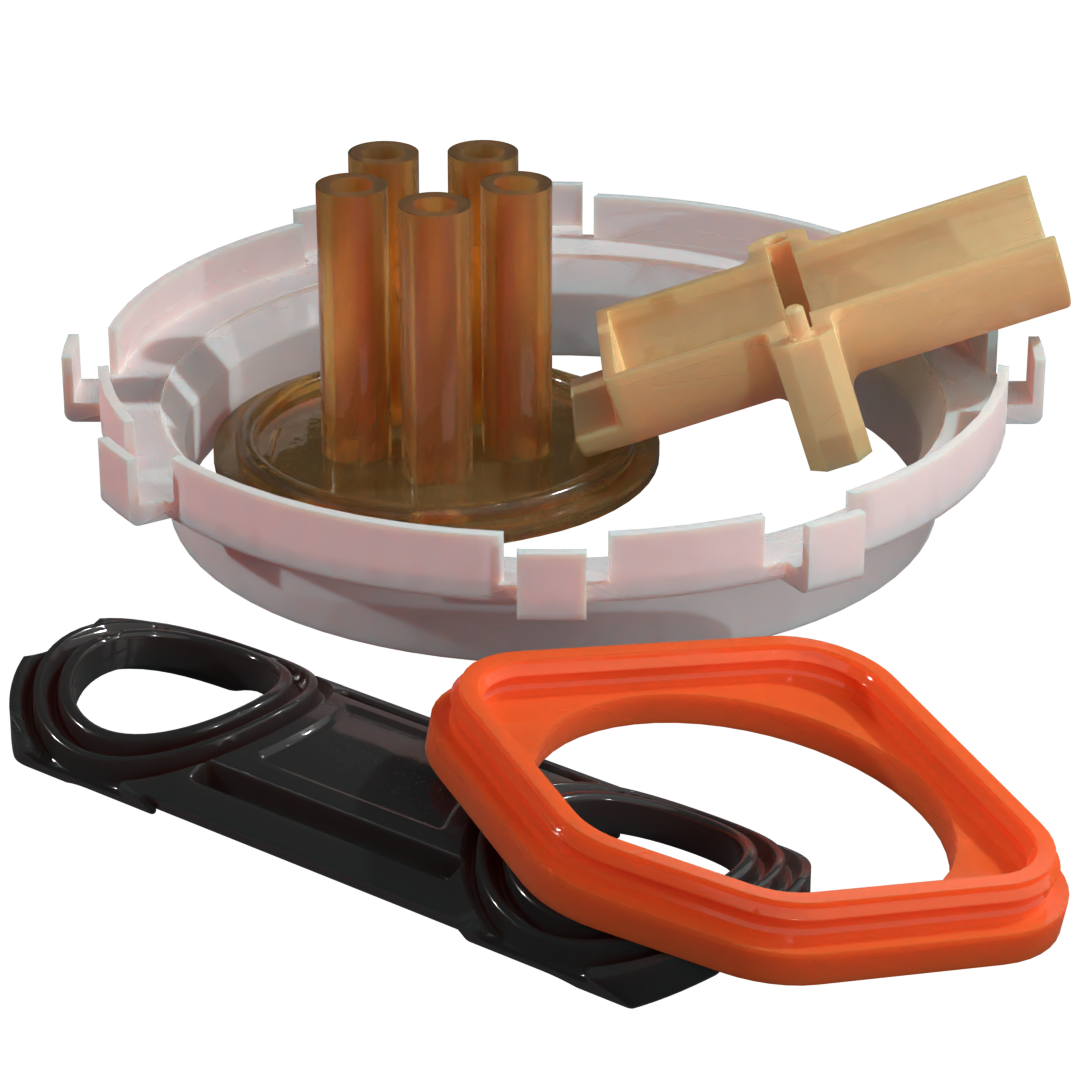

Custom Parts & Custom O-rings

Learn More

FAQ

Getting an accurate and timely quote for precision components often depends on how well project requirements are defined. At Canyon Components, we make the process as efficient and technical as possible. Whether you are sourcing standard AS568 O-rings, designing a custom molded seal, or needing specialized FFKM parts for high-purity or high-temperature environments, our quoting process is engineered to provide fast, reliable results. Each quote is reviewed by a technical specialist who considers material performance, compliance requirements, and manufacturing tolerances. Our engineering and sales teams work closely with customers to ensure every quote reflects the exact specifications and conditions of the intended application.

Can Canyon Components help if I am unsure which material or compound I need?

Yes. Many customers come to us without a finalized material choice. Our engineers will review your operating environment, including thermal cycling, fluid exposure, and mechanical load, to identify the most suitable elastomer, plastic, or metal. For instance, we may recommend FFKM compounds like Canrez® for extreme chemical resistance, FKM for high-heat stability, or EPDM for steam and water resistance. We can also suggest specialty blends or surface treatments to improve performance. If you are replacing a legacy part and do not know the compound, Canyon Components offers material testing and identification services, such as FTIR analysis, to find an equivalent or improved match. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How fast will I receive my quote?

Our standard response time for most quotes is within 24 hours, with many returned the same business day. Complex or custom projects that require additional engineering review may take slightly longer, especially if drawings or tooling specifications are being evaluated. Canyon Components prioritizes fast turnaround without compromising technical accuracy. We also provide expedited quoting for time-sensitive projects and can coordinate rapid manufacturing for prototype or production orders to help minimize downtime and keep schedules on track. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What if I need a large quantity or recurring order?

For large production runs or recurring orders, Canyon Components can establish blanket purchase agreements or consignment programs to ensure consistent supply and cost efficiency. This allows customers to lock in pricing, guarantee availability, and schedule releases over time. Our system supports volume-based pricing and long-term stocking agreements for high-demand parts, reducing lead times and minimizing production delays. Whether you need recurring deliveries for an assembly line or long-term storage for specialty materials, our team can design a custom logistics plan that fits your purchasing workflow.

Can Canyon Components produce prototypes or samples before full production?

Yes. We regularly provide samples, test runs, and prototypes to verify fit, performance, and material compatibility. Prototypes are available for molded, machined, and extruded parts. This step helps confirm that the design meets functional and dimensional requirements before mass production begins. Our in-house manufacturing and rapid tooling capabilities mean prototypes can be produced in the same materials and finishes as final production parts, ensuring accurate testing and validation results. Customers often use prototypes to evaluate seal performance under actual temperature, pressure, and chemical exposure before approving final production. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What industries does Canyon Components serve through its quoting and production services?

We work with customers across aerospace, medical, semiconductor, chemical, and industrial sectors, each with distinct material and compliance requirements. For aerospace, we quote parts made from AMS or MIL-SPEC materials like fluorosilicone and high-performance FKM. Medical and pharmaceutical customers typically require FDA, USP, or ISO-certified materials like platinum-cured silicone or EPDM. Semiconductor and chemical processing industries rely on FFKM, PTFE, and PEEK for low outgassing and chemical resistance. Our quoting team understands the nuances of each industry and can ensure that every recommendation aligns with the appropriate performance and certification standards.

Does Canyon Components provide documentation with quoted materials?

Yes. Every quote can include a complete documentation package depending on your needs. This may include Certificates of Conformance (CoC), material data sheets, REACH and RoHS compliance statements, batch traceability, and testing reports. For regulated applications, we also provide details on ASTM and ISO test results to confirm hardness, tensile strength, and compression set. Our quoting process ensures that compliance requirements are built in from the start, preventing delays and ensuring every delivered product meets the requested certification level. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components cross-reference part numbers from other brands?

Absolutely. We maintain a comprehensive cross-reference system that includes Kalrez®, Chemraz®, Parker®, Perlast®, and other major manufacturers. Customers often send competitor part numbers, and our team identifies the matching or equivalent Canrez® or Canyon Components formulation. In many cases, we can provide improved lead times or pricing while maintaining equivalent or superior performance. Our cross-referencing service is especially valuable for companies seeking alternative suppliers for discontinued or long-lead-time materials.

How does Canyon Components ensure competitive pricing?

Pricing is determined based on material, quantity, manufacturing method, and any special testing or documentation requirements. Canyon Components continuously evaluates its supply chain and material sourcing to maintain competitive costs without compromising quality. Because we work directly with compounding and molding facilities, we eliminate unnecessary markups and can offer pricing that reflects true manufacturing efficiency. For high-volume or long-term partnerships, we also provide cost-reduction programs, including tooling amortization and volume discounts.

What makes Canyon Components a dependable partner for engineered sealing and component solutions?

Canyon Components combines technical expertise, precision manufacturing, and responsive service in every quote and project. Unlike commodity suppliers, we approach every inquiry with an engineering-driven mindset, focusing on performance, reliability, and compliance. Our fast turnaround times, transparent communication, and deep material knowledge make us a trusted partner for both standard and custom sealing solutions. From initial quote to production and beyond, Canyon Components provides the technical support, quality assurance, and documentation needed to deliver dependable results for every customer and every industry.