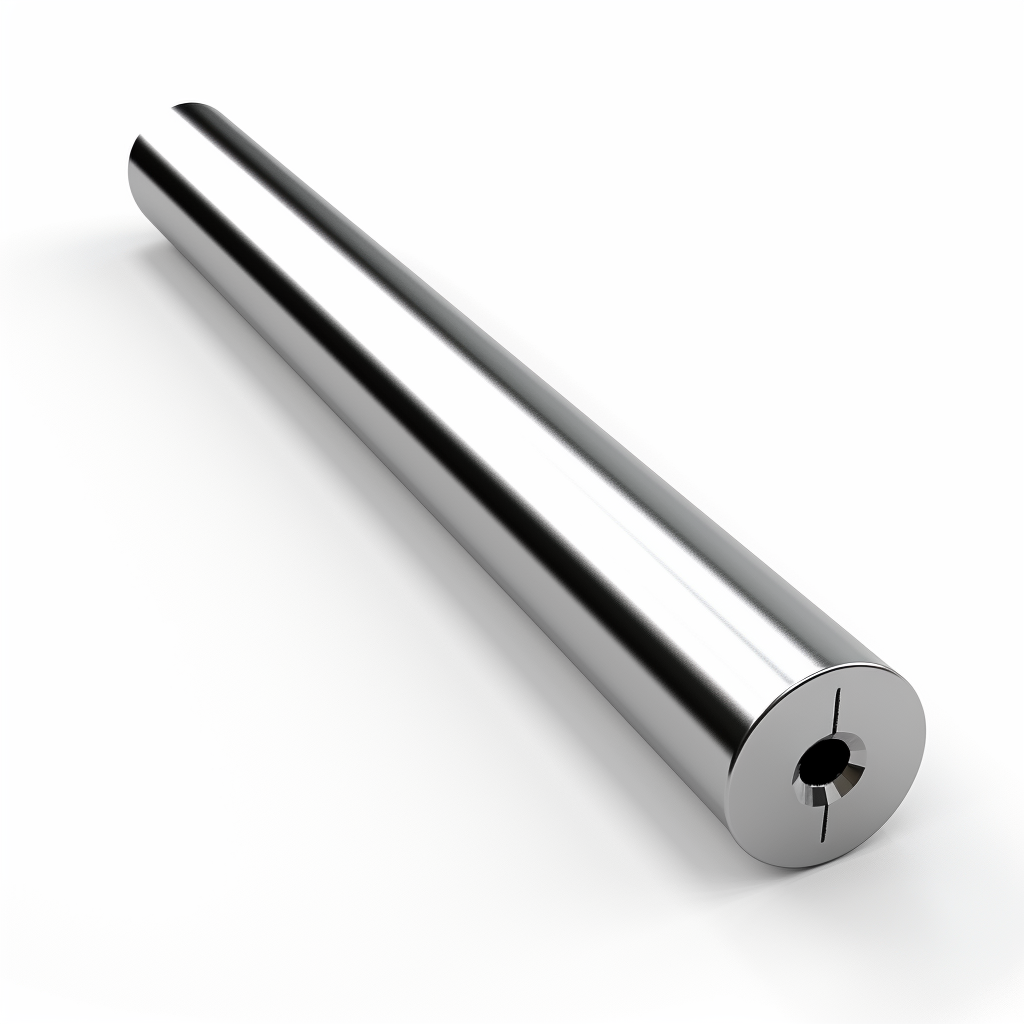

Alloy Steel Metal Selection Guide

Alloy steel is a versatile and widely used metal alloy that is primarily composed of iron and contains varying amounts of other alloying elements. These alloying elements are added to enhance specific properties, such as strength, corrosion resistance, and heat resistance. In this web page, we will explore the different types of alloy steel, its numerous advantages and disadvantages, and the diverse industrial uses where alloy steel plays a crucial role.

Alloy Steel rapid manufacturing, & machined parts are available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Common names include: Stainless Steel, Tool Steel, Chromium Steel, Nickel Steel, Vanadium Steel, Molybdenum Steel, Manganese Steel, Silicon Steel.

Advantages

- Enhanced Strength: Alloying elements improve the strength and hardness of steel, allowing for the construction of durable and load-bearing structures.

- Improved Corrosion Resistance: Some alloying elements, like chromium and nickel, impart corrosion resistance to alloy steel, making it suitable for use in harsh environments.

- High-Temperature Resistance: Certain alloying elements enhance heat resistance, enabling alloy steel to maintain its mechanical properties at elevated temperatures.

- Wear Resistance: Alloy steel can be engineered to exhibit excellent wear resistance, making it ideal for applications involving friction and abrasion.

- Versatility: Alloy steel's versatility allows for tailoring its properties to meet specific application requirements.

- Machinability: Depending on the alloy composition, alloy steel can be machined and fabricated with relative ease.

- Fatigue Resistance: Alloy steel can exhibit improved fatigue resistance, prolonging the service life of components subjected to cyclic loading.

Disadvantages

- Cost: Alloy steel can be more expensive than plain carbon steel due to the cost of alloying elements.

- Complexity: The wide variety of alloy compositions can make alloy steel selection and processing more complex.

- Weldability: Some alloy steels are less weldable than carbon steel and may require special welding procedures.

Common Applications of Alloy Steel

- Aerospace: Alloy steel is used in aircraft components, landing gear, and turbine engines due to its strength and heat resistance.

- Automotive: Alloy steel is used in automotive components such as axles, gears, and crankshafts for its strength and durability.

- Oil and Gas: Alloy steel is used in the oil and gas industry for pipelines, drilling equipment, and downhole tools due to its corrosion resistance and strength.

- Tool and Die Making: Tool steel is used to manufacture cutting tools, dies, and molds for various industrial processes.

- Construction: Alloy steel is used in construction for structural elements like beams, columns, and high-strength fasteners.

- Defense: Maraging steel is used in defense applications, including armor and missile components, due to its strength and toughness.

- Medical: Stainless steel, a type of high-alloy steel, is used in medical devices and surgical instruments due to its biocompatibility and corrosion resistance.

- Power Generation: Alloy steel is used in power generation equipment, including turbines and boilers, due to its high-temperature resistance.

- Manufacturing: Alloy steel finds applications in various manufacturing processes, including stamping, forging, and machining.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Types of Alloy Steel

Alloy Steel can come in different variations, depending on its composition and intended use. Some common types of Alloy Steel include the following.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Stainless Steel

Renowned for its corrosion resistance, stainless steel is a blend of steel with chromium and often nickel. It's widely used in kitchenware, medical instruments, and architectural structures. Its luster and resistance to staining and rust make it a popular choice for both functional and aesthetic applications.

Tool Steel

Characterized by its hardness and resistance to abrasion, tool steel is commonly used in cutting and drilling equipment. It often contains elements like tungsten, molybdenum, cobalt, and vanadium to enhance heat resistance and durability, making it ideal for tools and dies.

Carbon Steel Alloys

These alloys have higher carbon content than standard steel, improving hardness and strength. Used in high-strength applications like structural beams and automotive parts, carbon steel alloys are versatile but can be less ductile and more susceptible to corrosion.

Low Alloy Steel

Containing a smaller proportion of alloying elements (typically less than 5%), low alloy steel offers improved mechanical properties over standard carbon steel. It's used in pipelines, automotive components, and construction due to its enhanced strength and toughness.

High Alloy Steel

This type contains a higher percentage of alloying elements, giving it superior corrosion resistance and mechanical properties. It's used in aggressive environments like chemical processing plants and marine applications, where its durability and resistance to corrosive elements are essential.

Nickel Alloys

Steel blended with high nickel content exhibits excellent corrosion resistance and strength at high temperatures. Nickel alloys are particularly useful in extreme environments, such as jet engines, chemical plants, and oil rigs, due to their ability to withstand thermal and mechanical stress.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Manufacturing Options for Alloy Steel

Alloy Steel parts can be manufactured using several methods, each suitable for different applications and part complexities.

Each of these methods has its own advantages, limitations, and cost implications. The choice of manufacturing technique usually depends on factors like the complexity of the design, required precision, material properties, and production volume.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Back to Metals Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More