Custom Parts

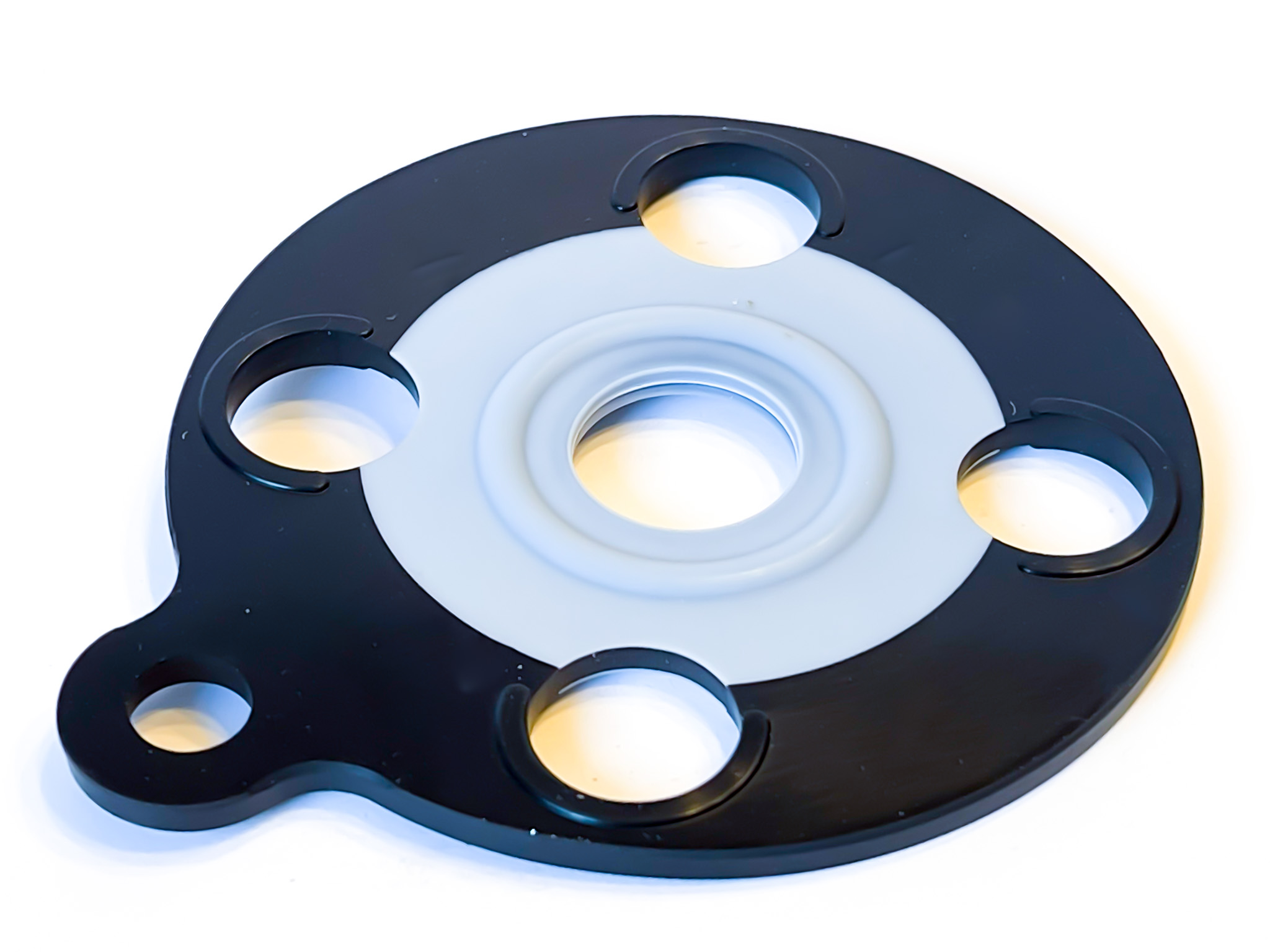

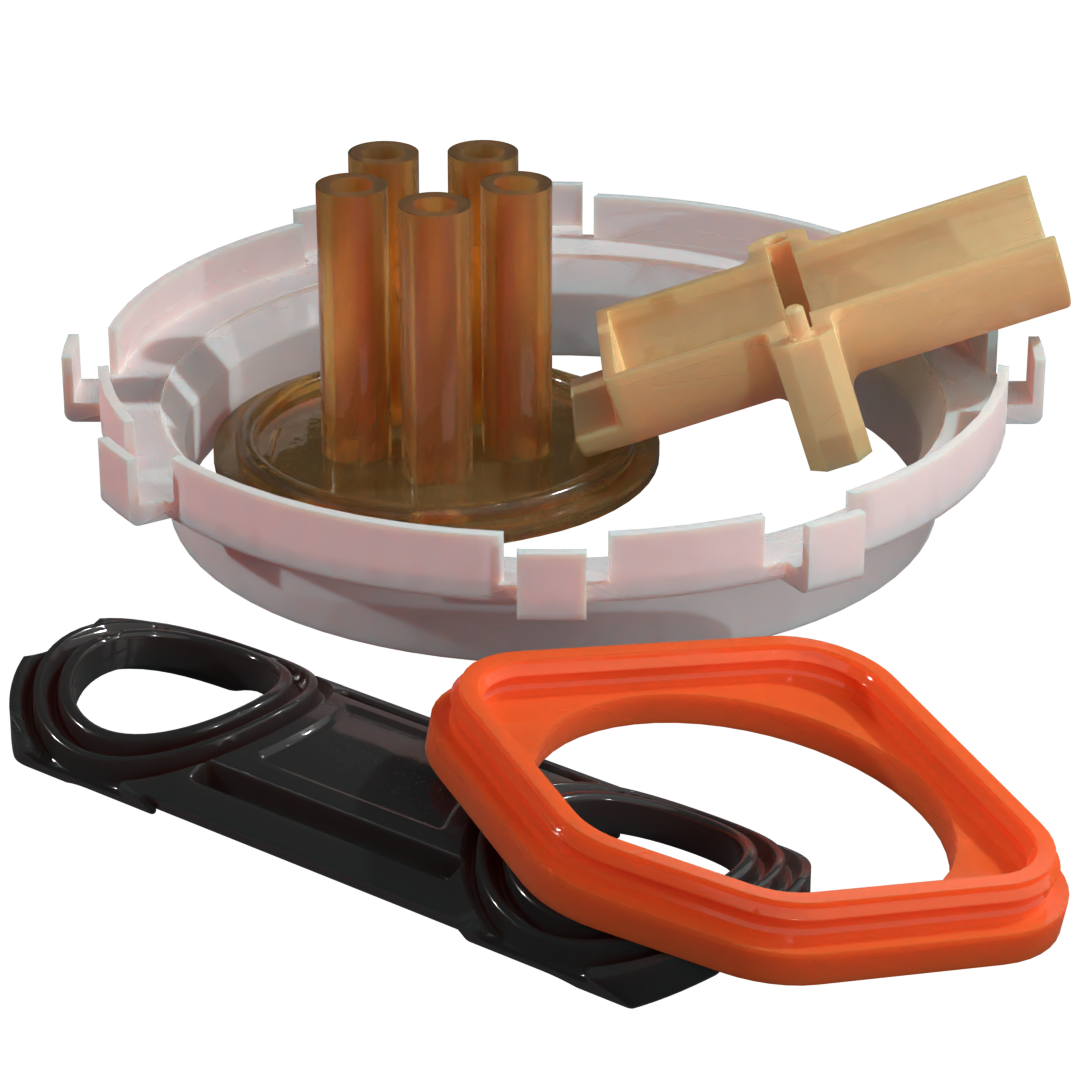

Here at Canyon Components, we understand the importance of well made, efficiently produced O-rings, gaskets, & custom molded parts. That's why we make sure to offer our customers any manufacturing technique they desire.

Whether your O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

We also offer rapid prototyping services and materials of virtually every specification requirement.

Canyon Components strives to meet all customer service requests. If you need something that isn't listed below, feel free to contact a Canyon Components product and application consultant and let our knowledgeable staff help you design the perfect part for your needs.

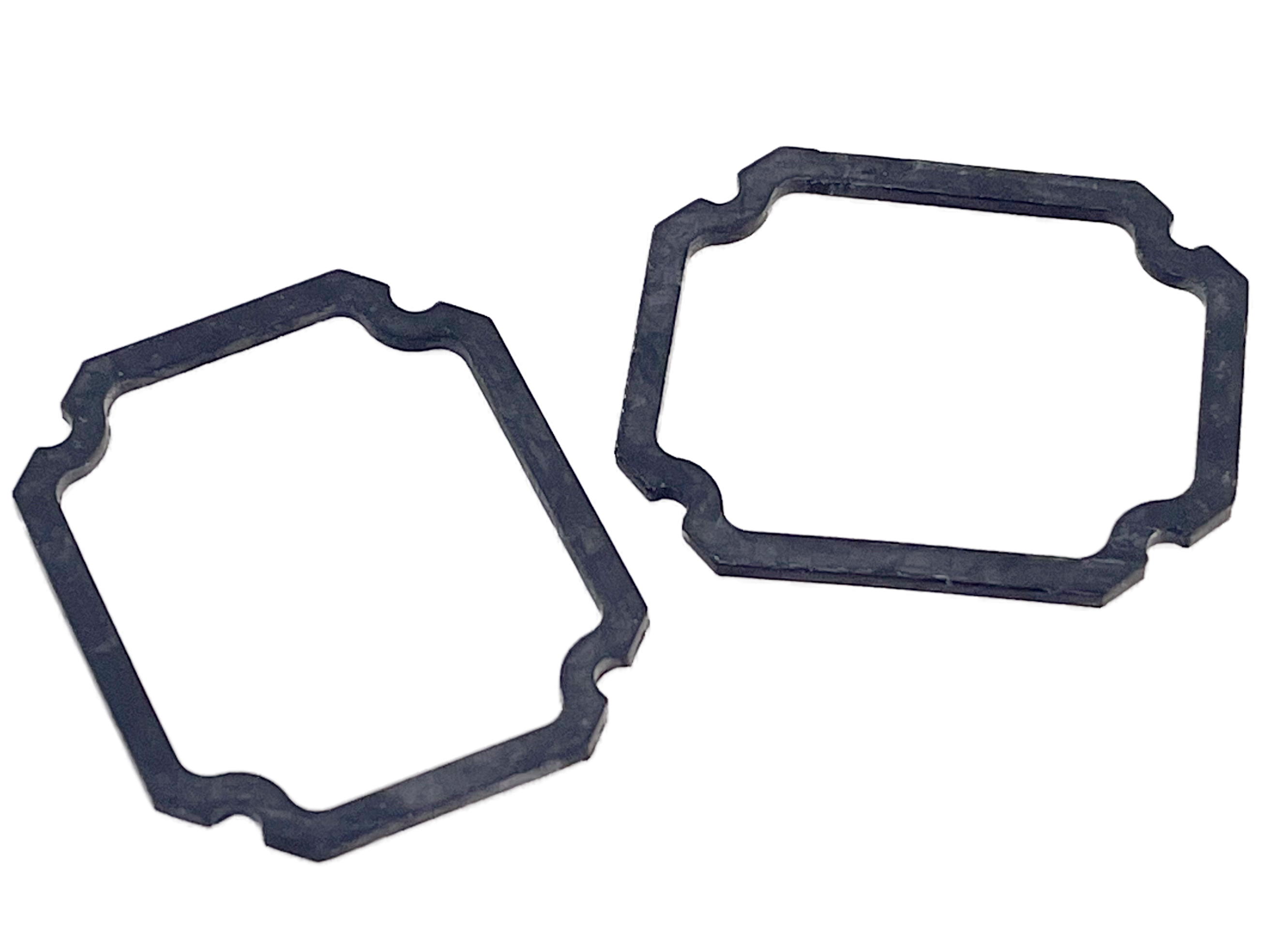

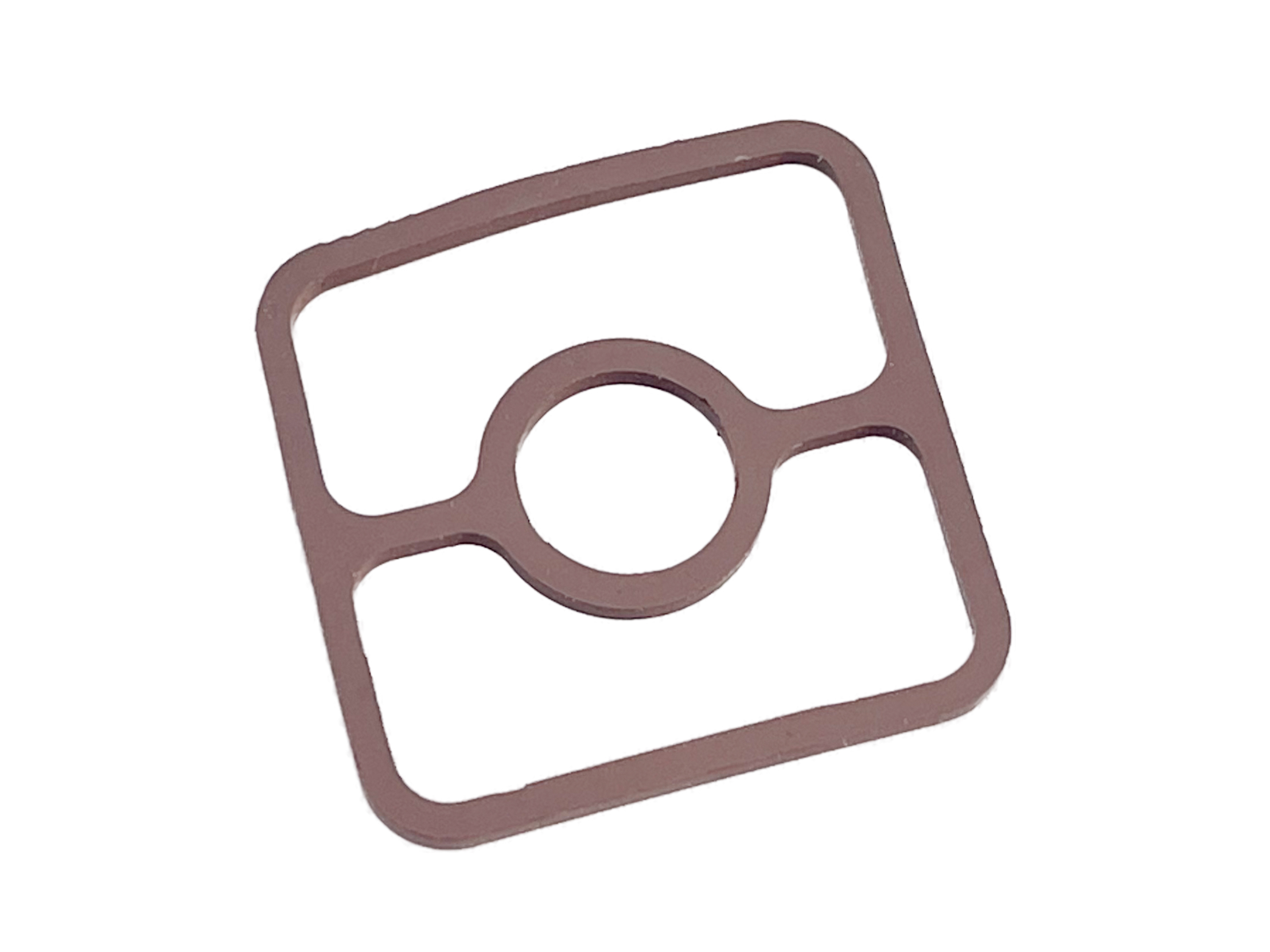

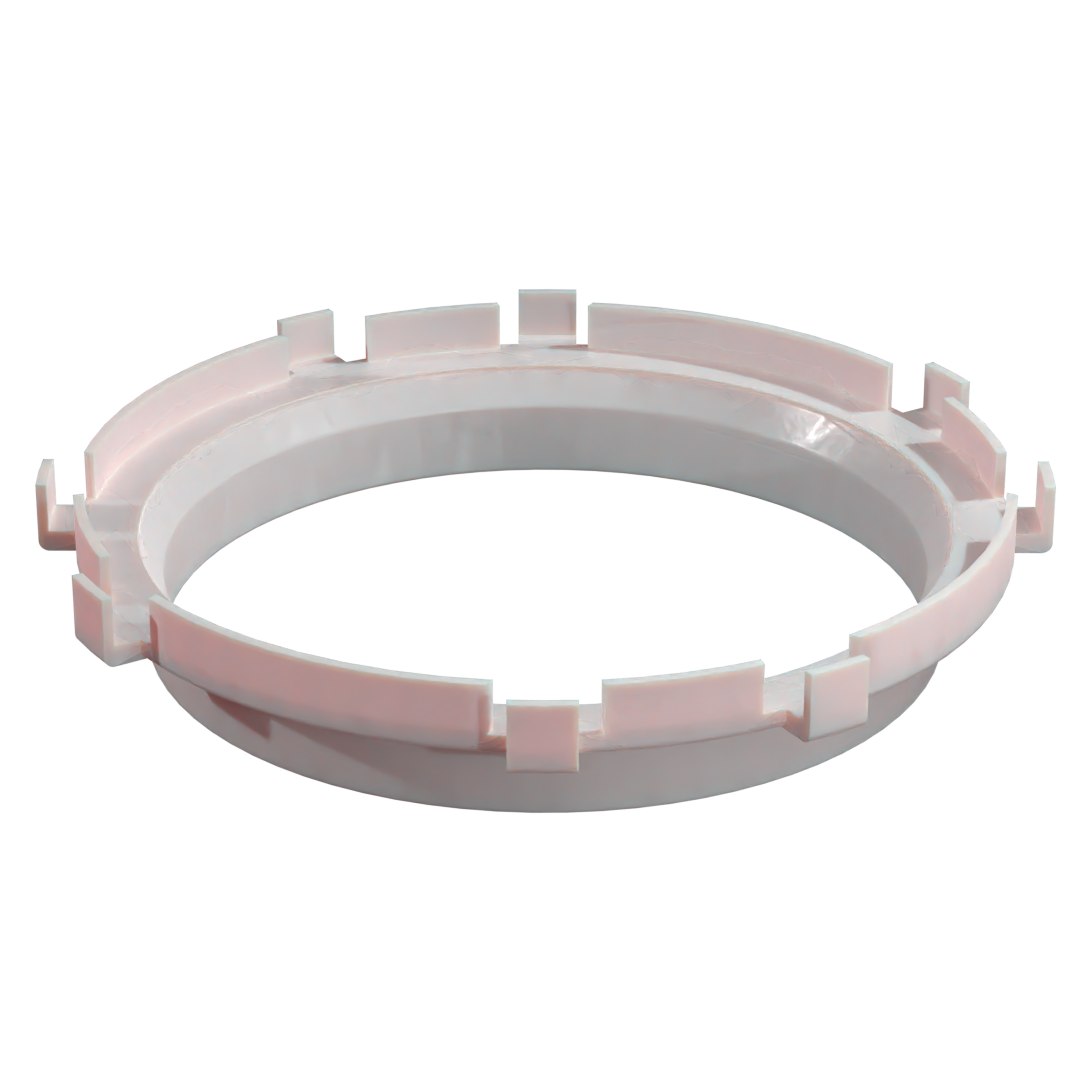

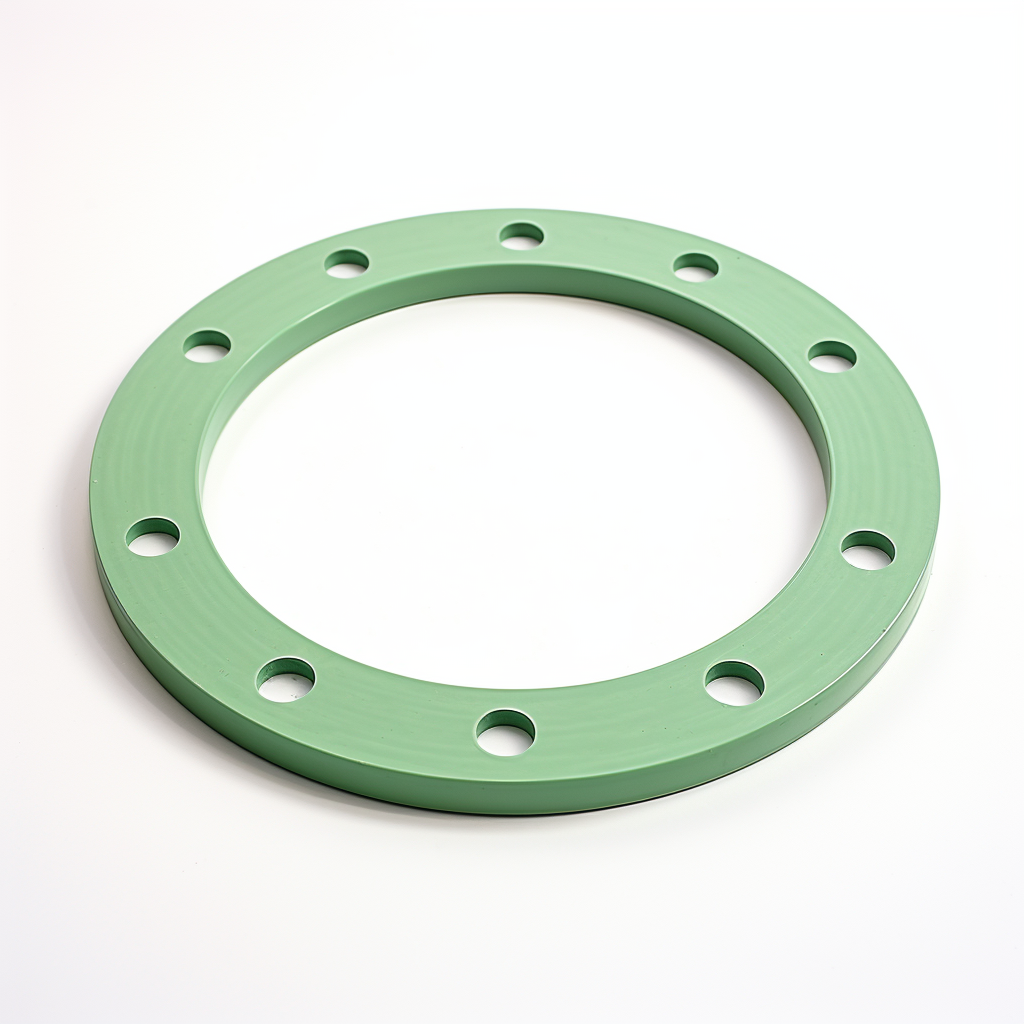

Gallery

Specific Custom Products

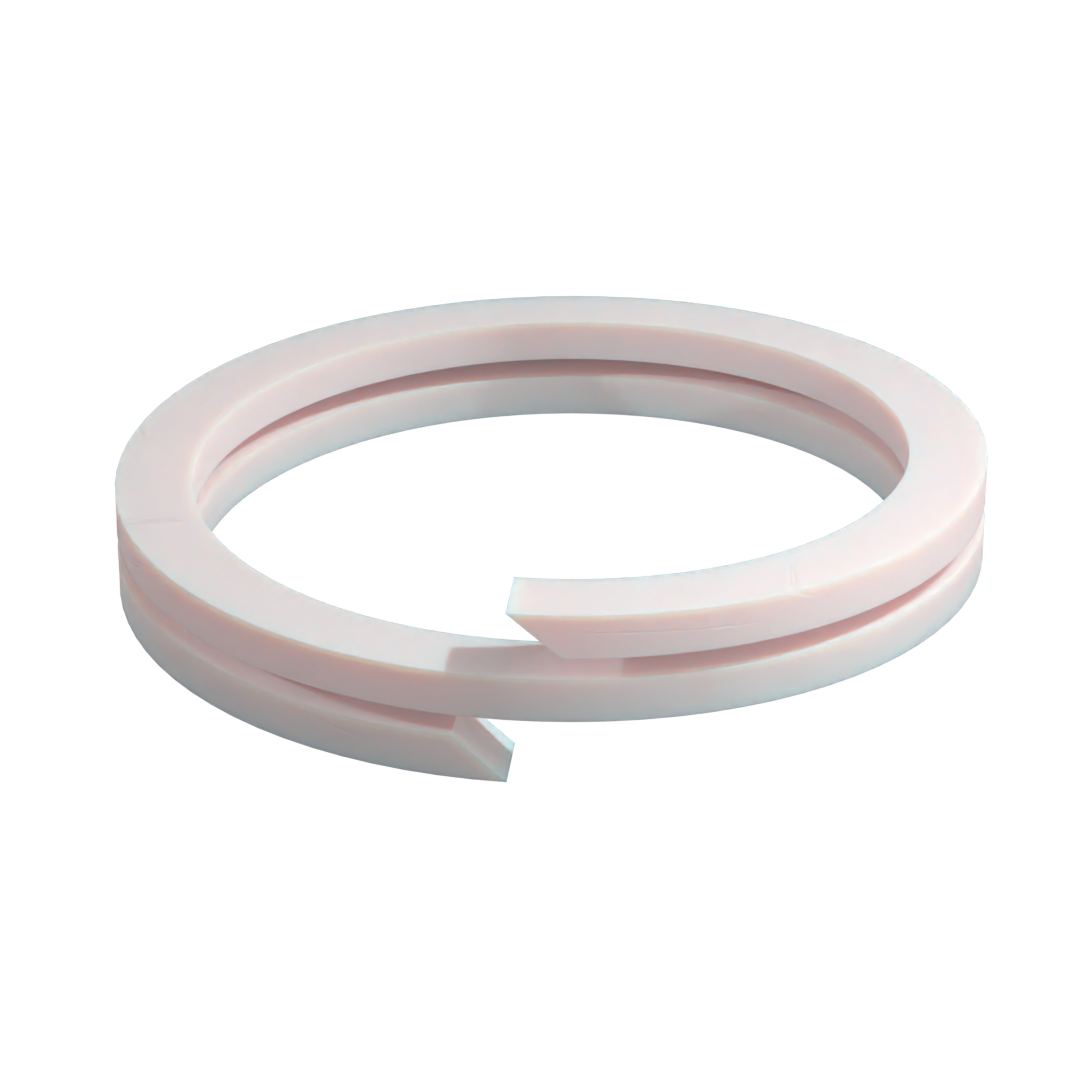

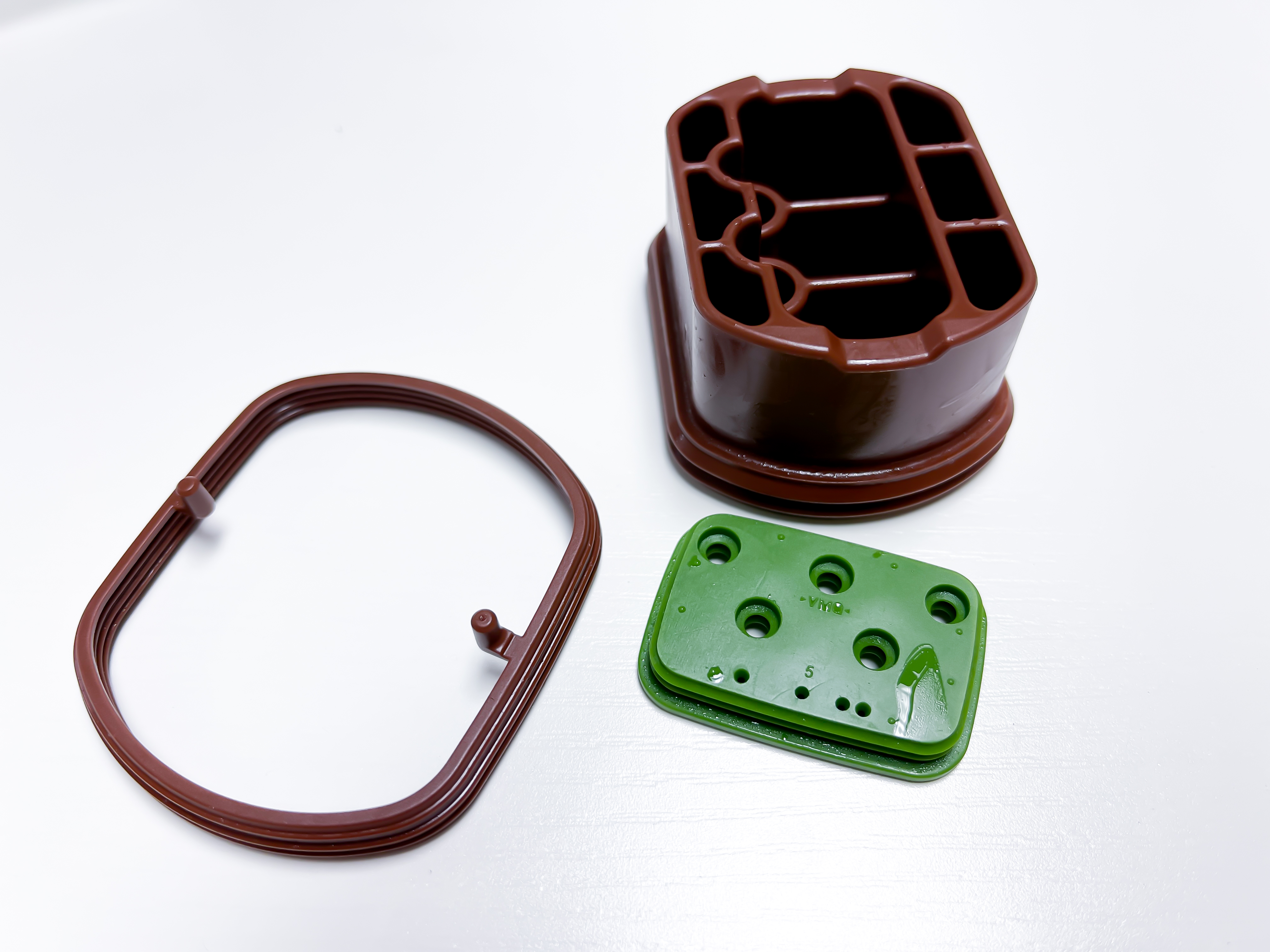

Custom Rubber Parts

Explore custom rubber parts tailored to your exact specifications. Learn about our material options, manufacturing processes, and how we deliver durable and reliable rubber components for various industries.

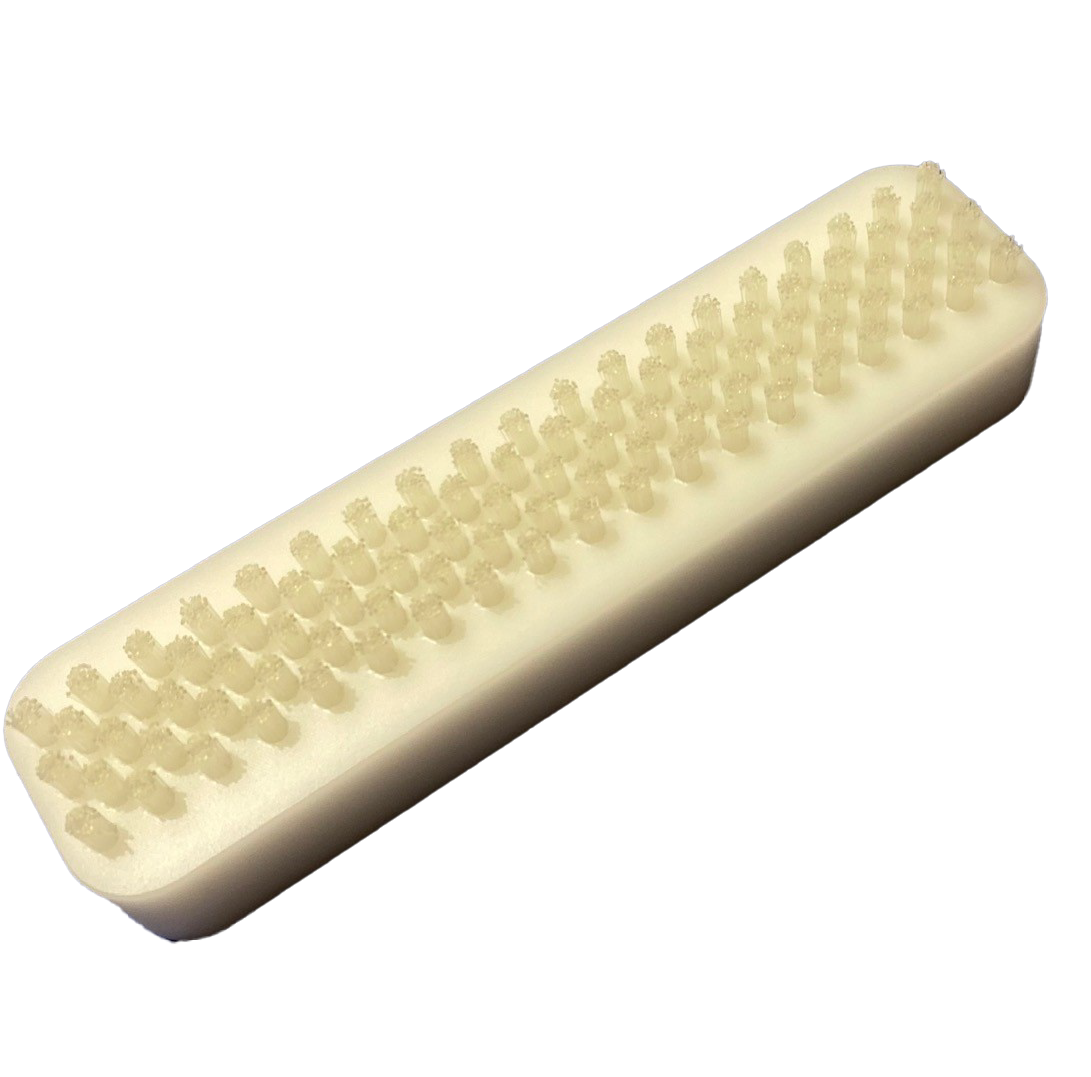

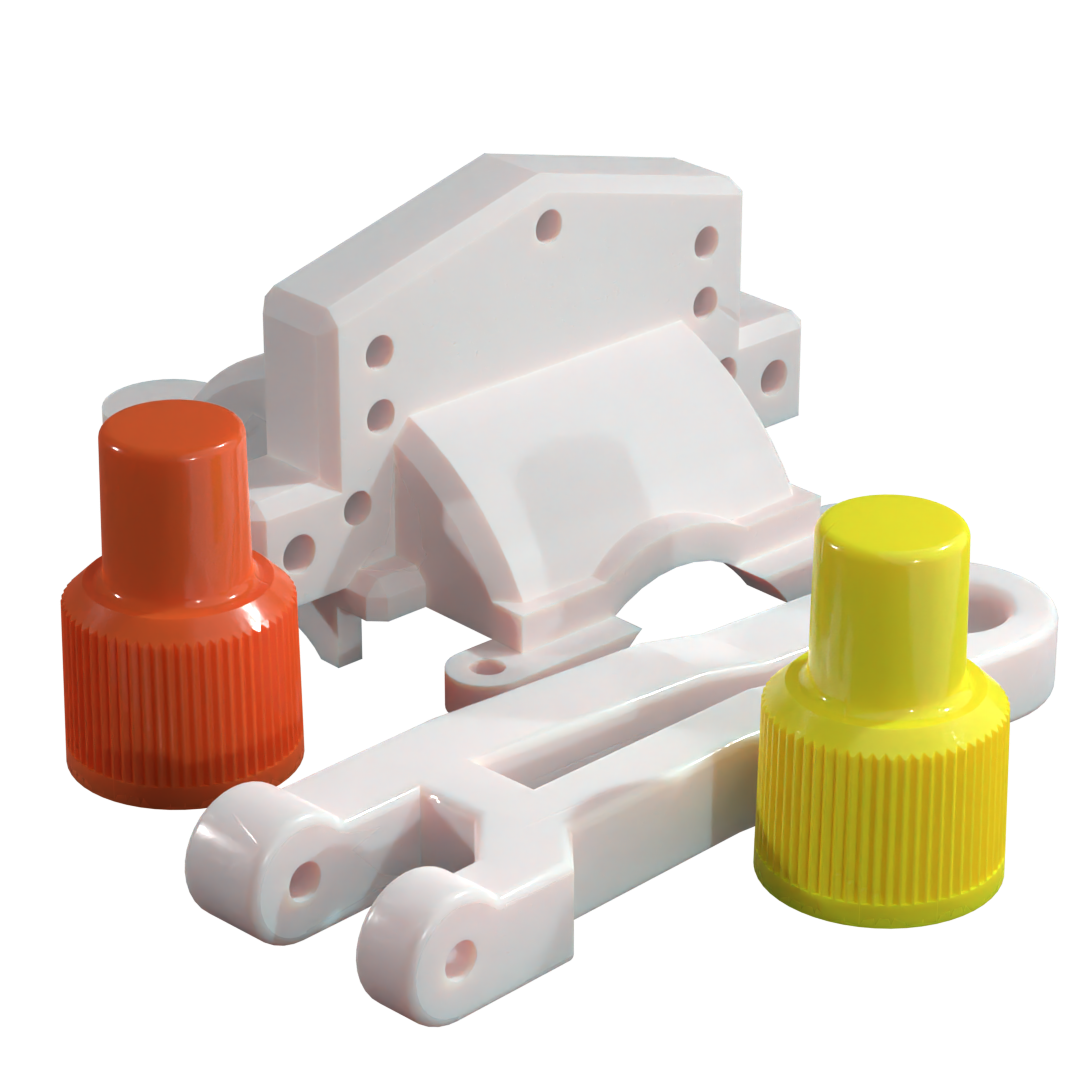

Custom Plastic Parts

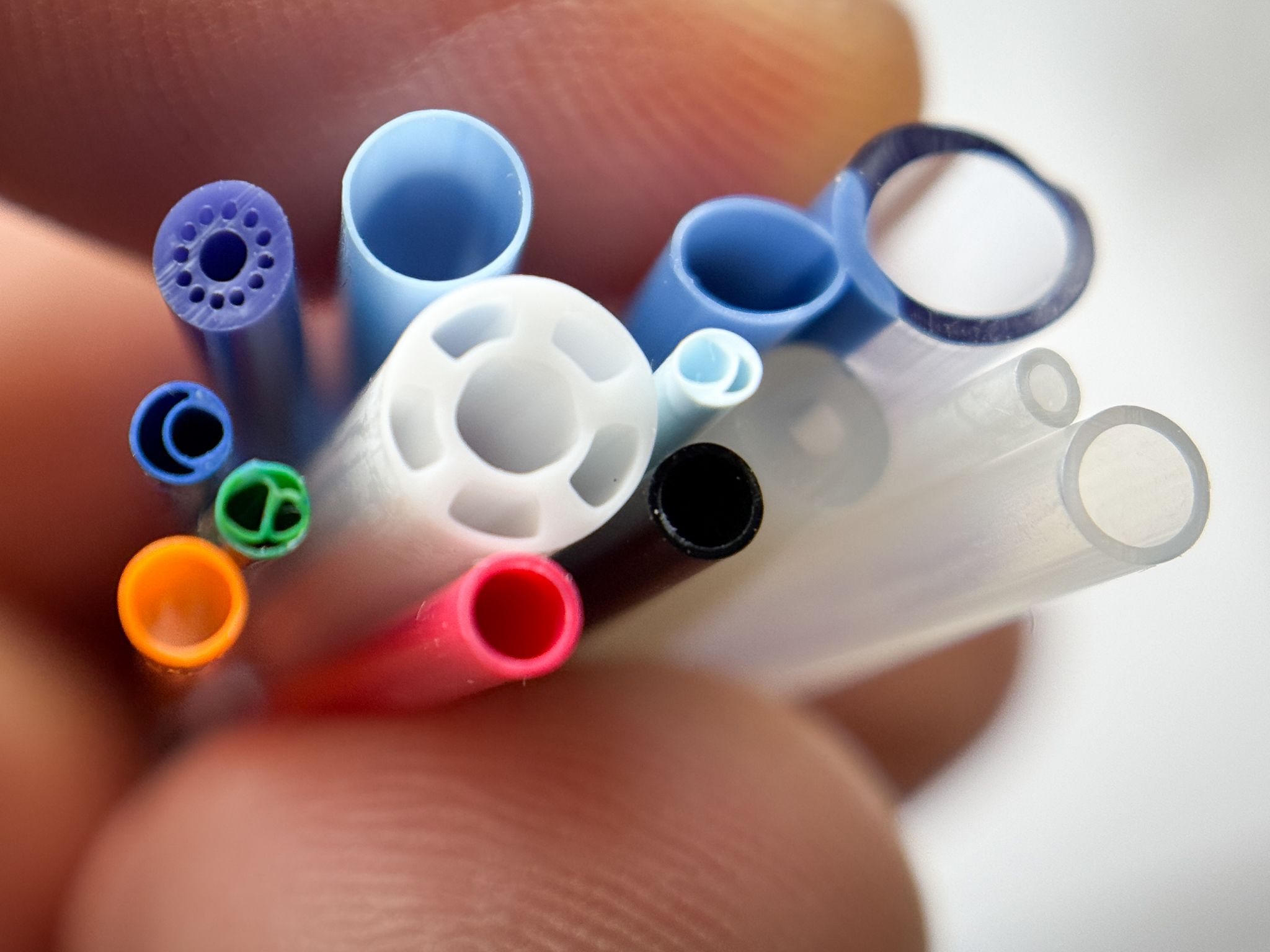

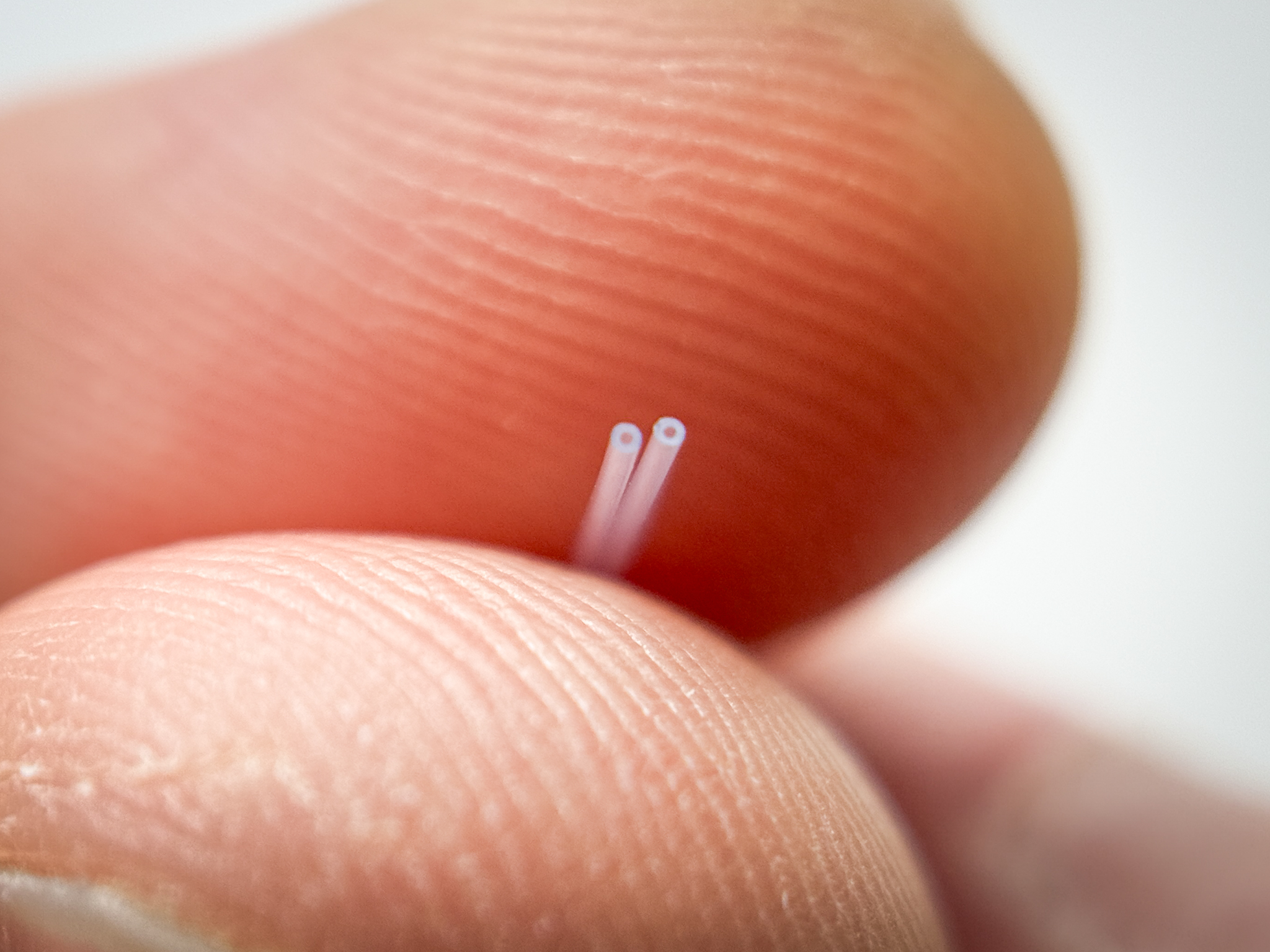

Discover custom plastic parts designed for your unique specifications. Learn about our advanced manufacturing processes, material options, and how we provide reliable, high-quality plastic components for various industries.

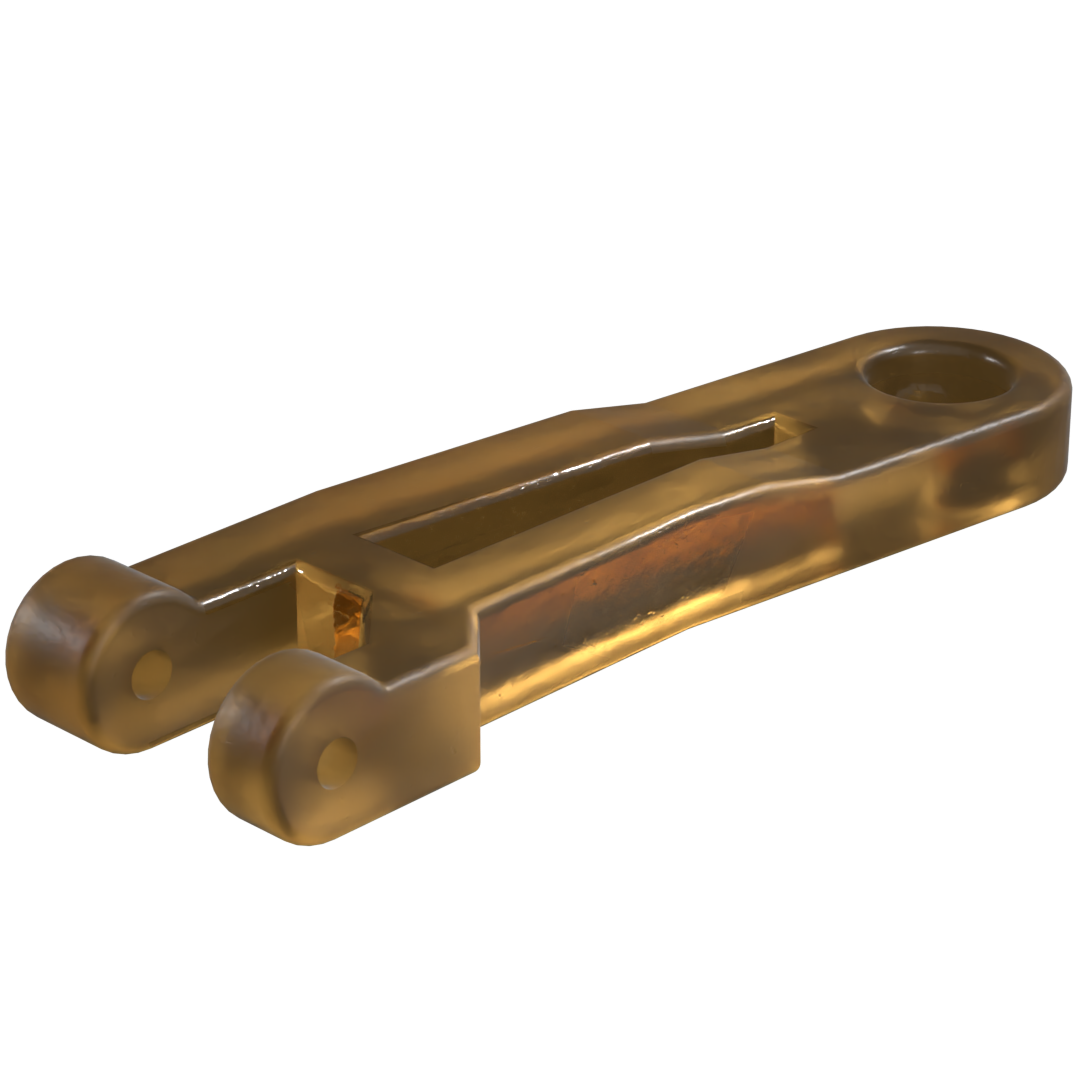

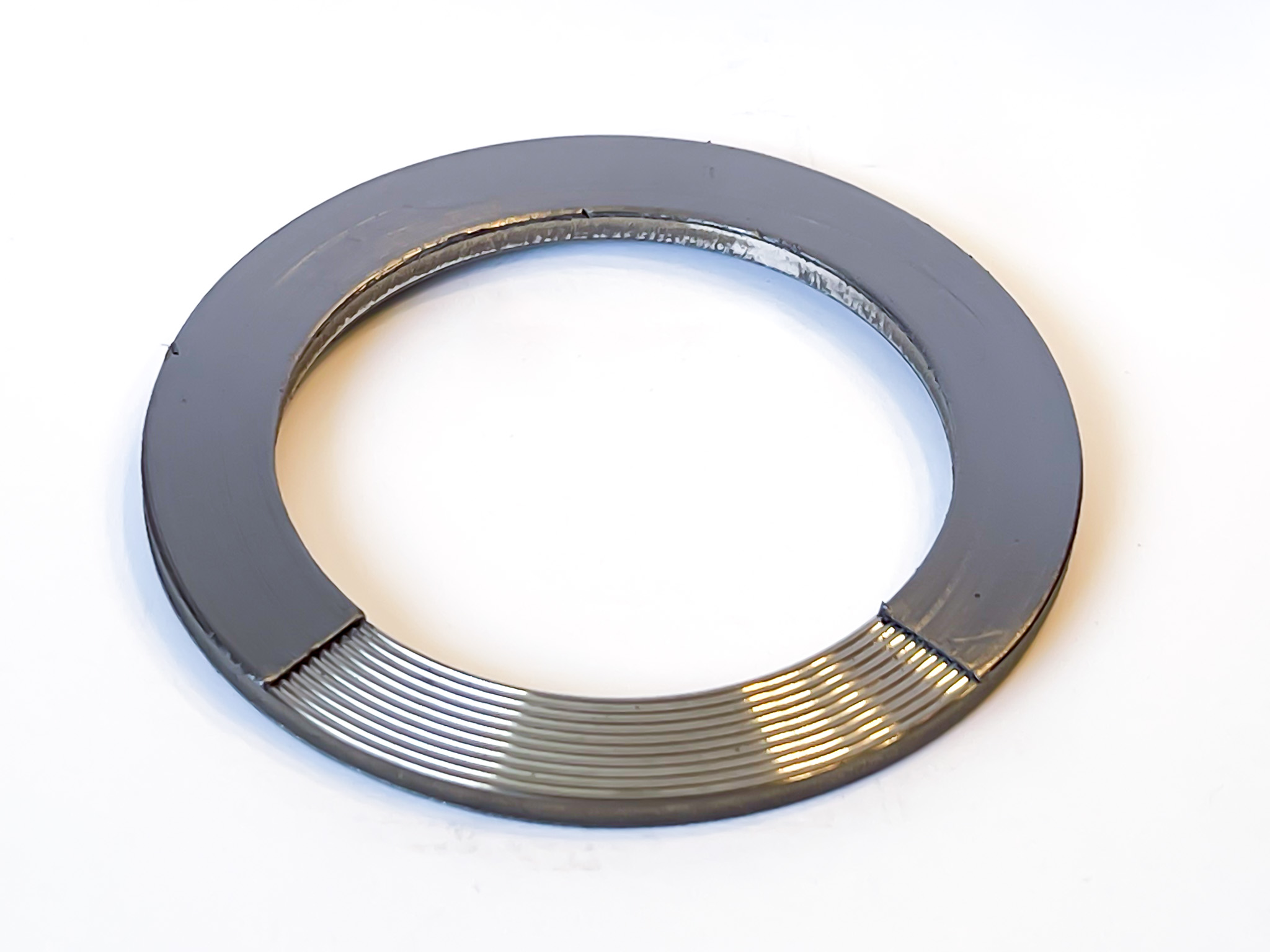

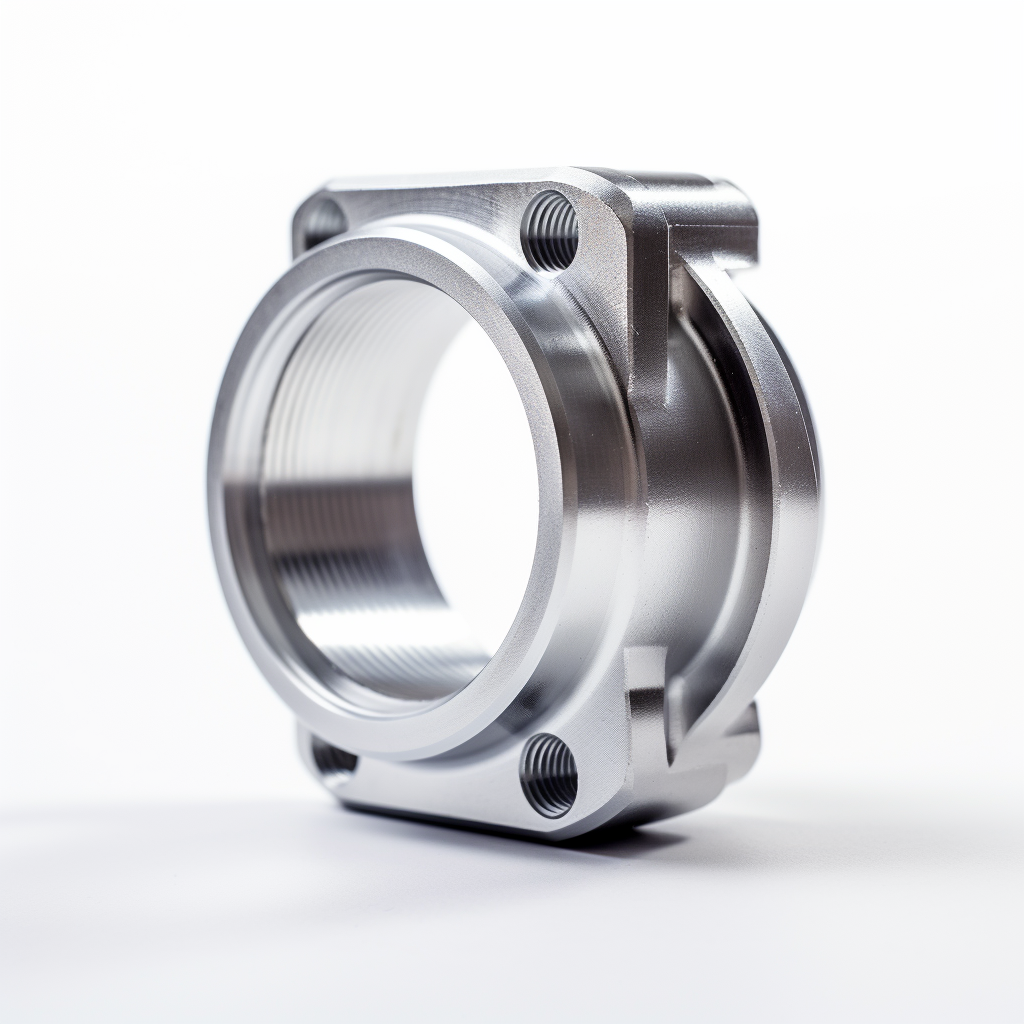

Custom Metal Parts

Explore custom metal parts designed to meet specific requirements across industries. Learn about our manufacturing capabilities, material options, and how we deliver precision-engineered solutions for your projects.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Parts Made To Your Specifications

Manufacturing & Design

- Your designs made to order

- Quoted quickly

- Engineering consultation

- O-ring, Gasket, & Custom Molded Part Injection Molding

- O-ring, Gasket, & Custom Molded Part Compression Molding

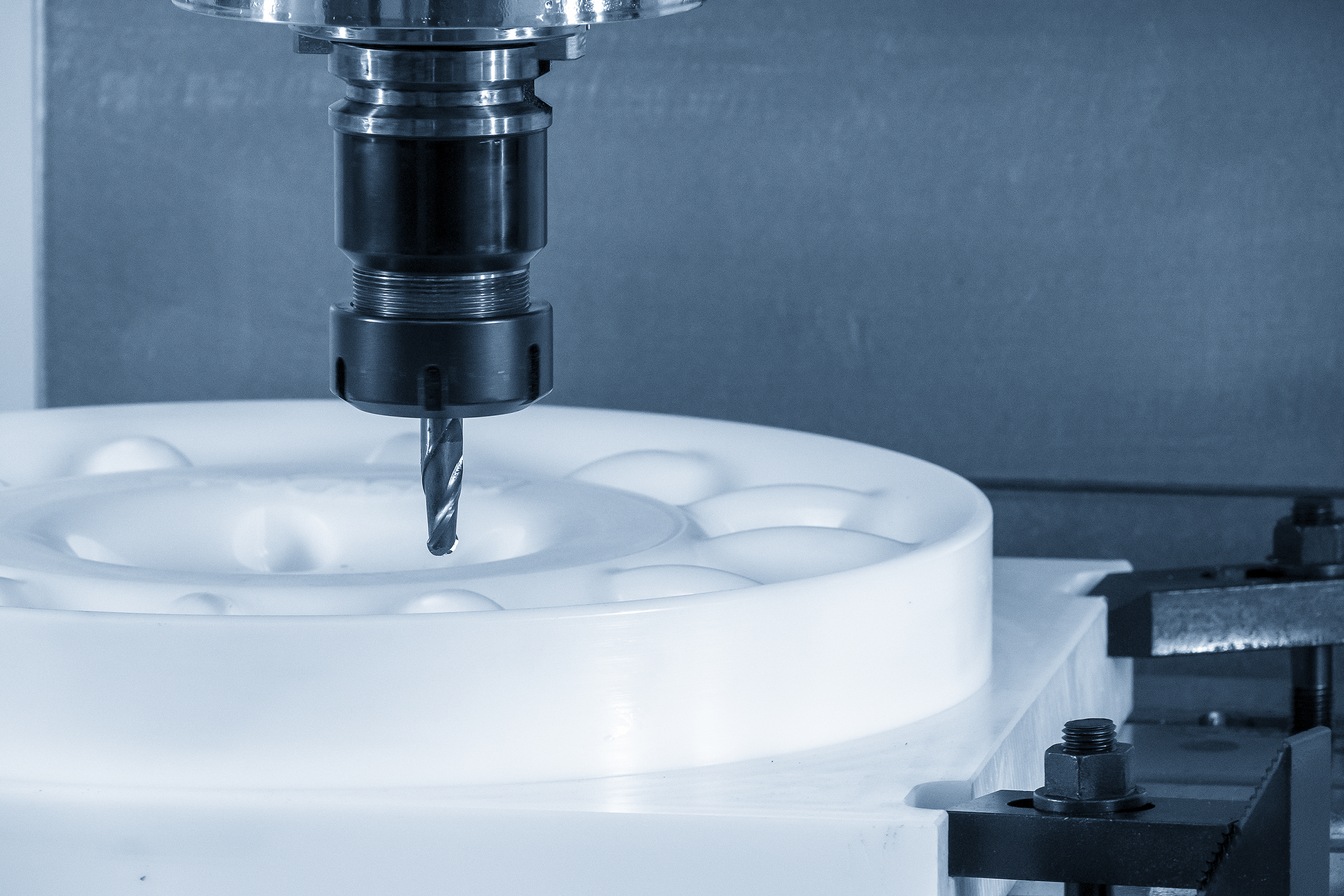

- Machining

- Rapid Prototyping

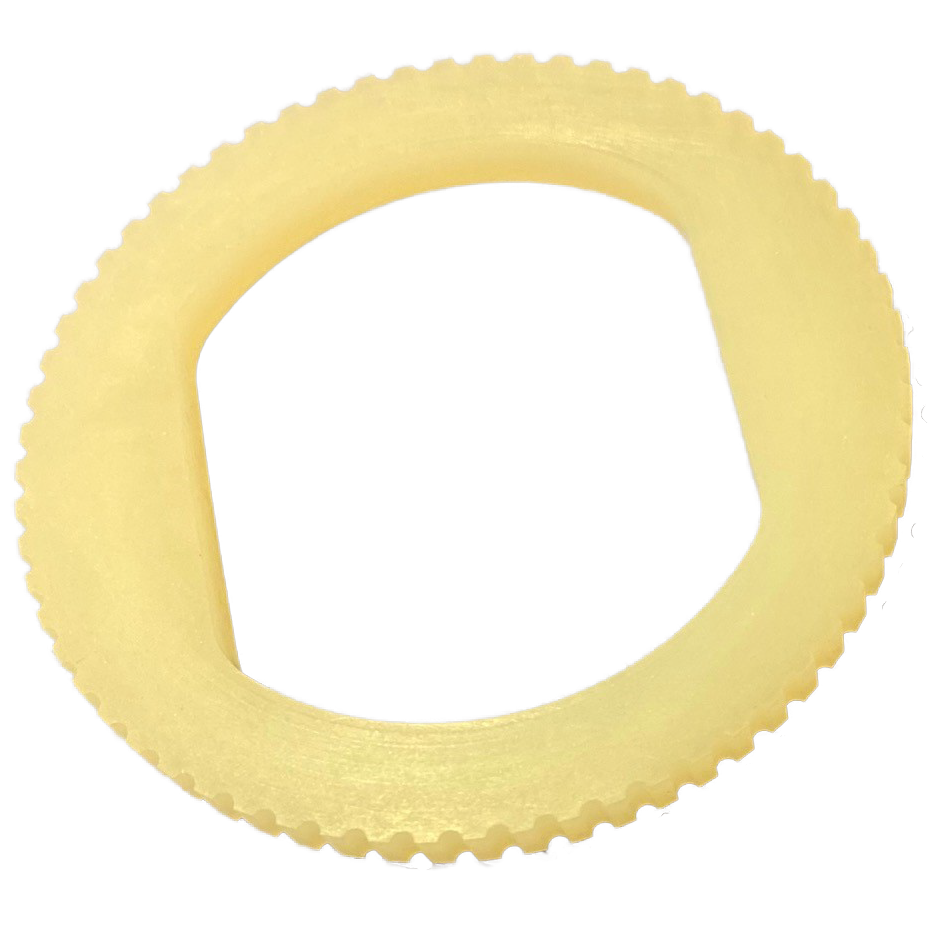

Custom & Standard Geometries

- Any O-ring, gasket, custom molded part, or custom geometry

- Plastic, Rubber, Metal

- Grommets, Bumpers, Bushings

- O-rings, gaskets, & custom molded parts, gaskets, diaphragms

- Sanitary seals

- Fasteners, bearings

- Metal parts

High Compliance Specifications

- USP VI {87} & {88} O-rings, gaskets, & custom molded parts

- FDA CFR 21.177.2600 O-rings, gaskets, & custom molded parts

- AED Norsok-M710 O-rings, gaskets, & custom molded parts

- AED NACE-TM0297 O-rings, gaskets, & custom molded parts

- NSF 61 & 51, KTW, WRAS O-rings, gaskets, & custom molded parts

- 3A sanitary compliance O-rings, gaskets, & custom molded parts

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Any Material, Any Geometry

With manufacturing capabilities focused in rubbers, plastics, and metals, Canyon Components can make even the most complex O-rings, gaskets, & custom molded parts a reality.

With Canyon Components suite of manufacturing techniques, no part is too difficult.

Canyon Components strives to meet all customer service requests. Feel free to contact a Canyon Components product and application consultant and let our knowledgeable staff help you design the perfect part for your needs.

Prototyping & Engineering Services

Often times, it is extremely useful to receive low volume prototype parts for preliminary testing. If you find yourself in a situation like this, Canyon Components has you covered. With rapid prototyping methods like 3D printing, CNC machining, and single cavity test molds, it is possible to produce low volume, ultra high quality O-rings, gaskets, & custom molded parts for your testing needs.

Canyon Components engineers are also available to assist in O-ring, gasket, & custom molded part design and consultation.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

High Compliance Specifications

Canyon Components proudly serves all industries. Whether you operate in the medical, food & drug, semiconductor, aerospace, military, or automotive industries, Canyon Components will have materials, O-rings, gaskets, & custom molded parts that meet your needs.

We also offer optional clean room manufacturing, specialty coatings, custom packaging for O-rings, gaskets, & custom molded parts. Please see our Services Page if you are interested in learning more.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you determine the perfect material for your needs.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Custom-engineered components allow manufacturers to achieve the exact performance, geometry, and material compatibility their applications demand. Canyon Components specializes in custom O-rings, gaskets, seals, and precision molded or machined parts made from rubber, plastic, and metal. Whether you need a prototype for a new design or high-volume production for an established product line, our engineering and manufacturing capabilities ensure precise tolerances, consistent quality, and dependable performance across industries such as aerospace, medical, semiconductor, energy, and industrial equipment manufacturing. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What materials are available for custom parts?

Canyon Components works with a broad selection of high-performance materials to ensure compatibility with the customer’s specific environment. Common elastomers include EPDM, FKM, FFKM, silicone, fluorosilicone, NBR, and HNBR for sealing and flexibility. For structural or insulation applications, we use PTFE, PEEK, Acetal, Nylon, UHMW, and other engineering plastics. Our metal parts are available in stainless steel, aluminum, brass, copper, titanium, etc., often combined with elastomer overmolding for hybrid designs. Material selection is based on the intended exposure to temperature, chemicals, pressure, and motion, allowing each custom component to balance performance and cost efficiency. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components create parts from customer drawings or samples?

Yes. We can work directly from 3D CAD files, technical drawings, or physical samples to create exact duplicates or improved replacements. Our engineering team uses advanced modeling software to evaluate dimensions, compression ratios, and tolerances before producing tooling or prototypes. For legacy or discontinued components, we offer reverse engineering and material identification services, using methods such as FTIR and durometer testing to determine compound composition and hardness. This process allows us to reproduce parts accurately, even when original specifications are unavailable. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does the custom manufacturing process work?

The process begins with design consultation and material selection, followed by 3D modeling, prototype creation, and validation testing. Once the design is approved, we produce precision molds or machining fixtures for full-scale manufacturing. Canyon Components supports both short-run prototypes and high-volume production, ensuring that each part meets customer-specific dimensional tolerances and quality requirements. We also provide secondary operations such as deflashing, coating, lubrication, bonding, and custom packaging to ensure every part is production-ready. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are prototypes available before full production?

Yes. Canyon Components offers rapid prototyping through machining, 3D printing, and short-run molding. Prototypes are made from production-grade materials whenever possible to ensure accurate testing of compression set, chemical compatibility, and dimensional fit. This stage helps customers verify performance before committing to tooling or large-scale production. For critical applications, we can provide functional prototypes with coatings, lubricants, or cleanroom packaging identical to final production conditions, ensuring that testing results reflect real-world performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components manufacture parts that combine multiple materials?

Absolutely. Many industries require components that integrate the flexibility of elastomers with the strength or conductivity of metals and plastics. Canyon Components produces metal-to-rubber bonded parts, overmolded seals, and hybrid assemblies for applications such as vibration isolation, electrical grounding, and pressure sealing. We also manufacture multi-durometer components that combine different hardness levels of rubber to balance sealing performance and structural rigidity. Each part is manufactured under controlled conditions to ensure perfect bonding and long-term adhesion between materials. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What quality standards and certifications apply to Canyon Components’ custom parts?

Quality and traceability are integral to every custom project. Canyon Components manufactures parts to meet or exceed standards such as ASTM, ISO 9001, AMS, MIL-SPEC, and FDA CFR 21.177.2600, depending on the customer’s requirements. For specialized sectors such as aerospace or medical devices, we can provide full material traceability, Certificates of Conformance, inspection reports, and batch documentation. Each production run undergoes dimensional verification, hardness testing, and visual inspection to ensure consistency across every batch of parts. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide coatings, lubricants, or surface finishes for custom parts?

Yes. We offer a range of surface treatments to enhance performance or simplify installation. Options include PTFE coatings, parylene coatings, plasma treatments, graphite or molybdenum lubricants, and silicone-based finishes. These treatments can reduce friction, improve chemical resistance, enhance dielectric properties, or prevent contamination. For cleanroom or sterile environments, Canyon Components applies coatings under tightly controlled conditions to ensure purity and consistent film thickness. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How are custom parts packaged and delivered?

Canyon Components tailors packaging and delivery to each customer’s needs. We offer vacuum sealing, moisture-barrier packaging, cleanroom packaging, and barcoded labeling for inventory control. Custom kits, trays, or part groupings can also be created to support assembly line integration or field maintenance. With our optimized logistics and stocking programs, we ensure on-time delivery for both recurring orders and urgent production needs, minimizing downtime for OEM and industrial customers. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a trusted source for custom-engineered parts?

Canyon Components combines material expertise, precision tooling, and fast, responsive service to provide high-quality custom parts at every production scale. Our collaborative approach ensures each design is optimized for manufacturability, performance, and cost. From specialized elastomer seals to hybrid metal-rubber components, we deliver parts that meet demanding performance and regulatory standards. Customers across aerospace, medical, and industrial sectors rely on Canyon Components for technical guidance, reliable manufacturing, and consistent quality from prototype to production. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!