Adhesives

Welcome to the Canyon Components Adhesives Hub — your central resource for exploring high-performance industrial adhesive solutions. From fast-curing cyanoacrylates and vibration-resistant threadlockers to robust methacrylate structural adhesives and specialty bonding systems, we offer a wide range of adhesive technologies designed to meet the toughest engineering challenges.

Whether you're bonding plastics, metals, composites, or elastomers, our curated selection includes trusted brands like Loctite®, Permabond®, 3M Scotch-Weld™, LORD®, Devcon®, and more. Each adhesive is supported by in-depth technical guidance and real-world performance data to help you find the right fit for your application—whether you’re in aerospace, automotive, electronics, medical device manufacturing, or general industrial assembly.

Explore detailed pages by adhesive type, compare properties, and request a quote for your project. Whether you're prototyping or scaling up for production, our adhesives hub has you covered.

The engineers and consultants here at Canyon Components take pride in finding the perfect solution our customer’s needs. Contact our expert staff for assistance with any seal or application questions!

Adhesives

Cyanoacrylate Adhesives: Fast-Setting Bonding for Precision Applications

Explore cyanoacrylate adhesives, known for rapid bonding and high strength on a variety of substrates. Learn about their features, types, and uses in medical, electronics, automotive, and general assembly.

Threadlocker Adhesives: Secure Fastening Solutions for Vibration and Leak Resistance

Discover threadlocker adhesives designed to prevent loosening, leakage, and corrosion in threaded fasteners. Learn about their types, strengths, and applications in automotive, aerospace, and machinery assembly.

Methacrylate Adhesives: Structural Bonding for Metals, Plastics, and Composites

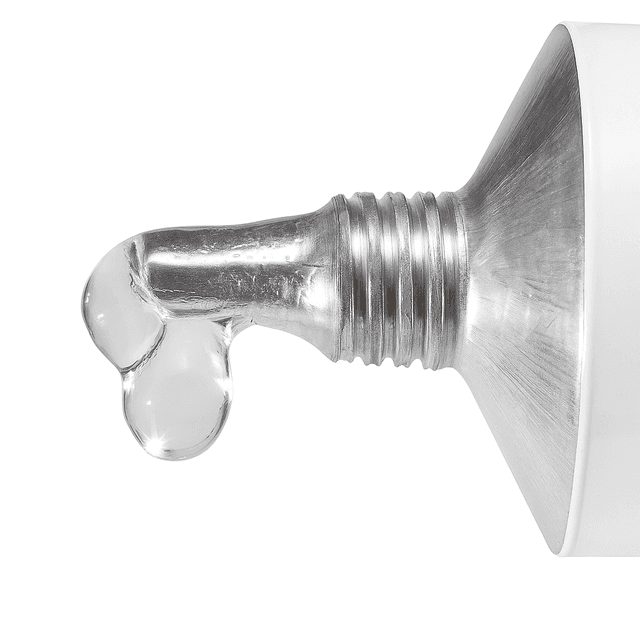

Explore methacrylate adhesives, high-strength structural solutions ideal for bonding dissimilar materials. Learn about their features, rapid curing, and use in automotive, marine, and industrial assembly.

Hot Melt Glue: Fast-Bonding Adhesive Solutions for Industrial Use

Discover hot melt glue, a versatile adhesive known for quick setting and strong bonds. Learn about its applications, types, and benefits for packaging, woodworking, electronics, and more.

Specialty Double-Sided Tapes

Explore specialty double-sided tapes engineered for strength, precision, and clean bonding. Learn about adhesive options for mounting, gasketing, and high-temp applications across automotive, electronics, and construction industries.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Adhesives and tapes are the unseen backbone of modern manufacturing, joining components, sealing surfaces, and reinforcing assemblies in industries ranging from aerospace to electronics. They offer strong, clean, and versatile alternatives to mechanical fasteners and welding. Canyon Components’ Adhesives Hub brings together both liquid and film-based bonding solutions, including cyanoacrylates, methacrylates, threadlockers, hot melt adhesives, and pressure-sensitive tapes. These products are designed to improve assembly strength, vibration resistance, and chemical durability for materials such as metals, plastics, composites, glass, and elastomers. Our engineering team provides end-to-end support, helping manufacturers select and apply the most effective bonding or taping solution for performance-critical applications.

How do industrial tapes compare to liquid adhesives?

Tapes provide immediate handling strength and eliminate the mess and curing time associated with liquid adhesives. They are particularly effective for large or uneven surfaces, lightweight materials, or environments where mechanical fasteners are undesirable. Unlike adhesives, tapes also serve as insulators and vibration dampers, helping reduce noise and structural stress. Canyon Components offers pressure-sensitive and transfer adhesive tapes that maintain adhesion across temperature extremes, UV exposure, and chemical contact. While tapes provide ease and cleanliness, liquid adhesives are ideal for complex geometries or small components where precise flow and penetration are needed. Many customers use a combination of both for optimized bonding performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the advantages of cyanoacrylate adhesives?

Cyanoacrylates, often known as instant adhesives or "superglue", bond rapidly to most materials, forming a rigid, durable connection within seconds. Their fast cure rate makes them ideal for assembly lines, electronic components, and small elastomeric seals. Canyon Components supplies advanced cyanoacrylate formulations that are low-odor, low-bloom, or rubber-toughened for better impact and peel strength. These adhesives work especially well for rubber-to-metal and plastic-to-plastic applications. When used with compatible primers, they can also bond low-energy materials like polyethylene or silicone. Our team helps match viscosity, cure time, and temperature tolerance to each customer’s process for maximum precision and durability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

When should methacrylate adhesives be chosen over other types?

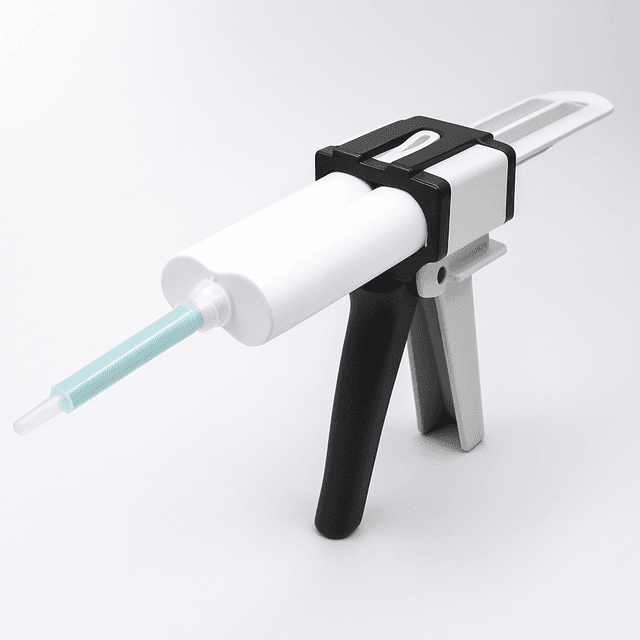

Methacrylate adhesives excel in structural applications where high shear, peel, and fatigue resistance are critical. They combine toughness and flexibility, bonding metals, composites, and plastics without the need for surface pretreatment. In automotive, marine, and aerospace manufacturing, they are often used as a replacement for welding or riveting. Canyon Components provides two-part methacrylate systems that cure quickly and tolerate slight surface contamination, making them ideal for field use or large assemblies. They also maintain bond strength under vibration, UV exposure, and temperature cycling. Our engineers evaluate substrate compatibility, bond area, and environmental stress to recommend the correct formulation for each structural application. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How are industrial threadlockers used in mechanical assemblies?

Threadlockers prevent loosening of threaded fasteners caused by vibration, temperature change, or stress. These anaerobic adhesives cure in the absence of air and in contact with metal, creating a solid, chemical-resistant bond that also seals threads against corrosion or leakage. Canyon Components offers removable, medium-strength, and permanent threadlockers for a variety of industries. They are widely used in pumps, engines, and precision machinery where reliability and maintenance efficiency are essential. Compared to mechanical locking hardware, threadlockers provide uniform clamping force and eliminate fretting corrosion, improving safety and part longevity. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What types of industrial tapes are available, and how are they used?

Industrial tapes come in many varieties, each tailored to a specific use. Acrylic foam tapes and VHB (Very High Bond) tapes are ideal for structural applications that require long-term adhesion and vibration damping. Double-sided tapes provide invisible, flexible bonding for panels, trims, and lightweight parts. PTFE tapes are used as anti-stick or low-friction liners for dynamic seals, valves, and threaded fittings. Canyon Components also supplies thermal interface and EMI-shielding tapes for electronics and aerospace applications. Each tape is available in custom die-cut shapes, rolls, or sheets, with backing materials that suit temperature, chemical, or UV exposure conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can hot melt adhesives and tapes be used together?

Yes. Combining hot melt adhesives with pressure-sensitive tapes can create hybrid bonding systems for specific manufacturing needs. For example, hot melts can provide structural bonding strength, while tapes offer instant tack for alignment and temporary positioning. Canyon Components supplies both thermoplastic-based hot melts for high-speed production and high-temperature reactive grades for stronger, long-term bonding. We also offer application guidance for optimizing viscosity, open time, and melt temperature to ensure consistent bond strength when used alongside tapes or primers. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What factors influence the strength and longevity of adhesive or tape bonds?

Bond performance depends on several factors including surface energy, cleanliness, temperature, and environmental exposure. Smooth, clean, and properly prepared surfaces yield the strongest bonds. Excessive moisture, oil, or oxidation can weaken adhesion over time. Canyon Components provides surface preparation guides, primers, and plasma treatment options to improve bond reliability. We also perform testing for shear, peel, and impact strength to verify product suitability under real-world conditions. Environmental factors like UV exposure, humidity, and chemical contact are considered during selection to ensure long-term adhesion stability.

How are adhesives and tapes used in temperature or chemical-sensitive environments?

In environments with high heat, cold, or chemical exposure, choosing the right adhesive chemistry is critical. Silicone-based adhesives and PTFE-backed tapes perform exceptionally in thermal cycling or chemical processing applications. Epoxy and methacrylate adhesives handle sustained high temperatures, while acrylic tapes maintain adhesion through UV and moisture exposure. Canyon Components provides products validated under ASTM and ISO testing protocols for thermal and chemical endurance. Our experts guide customers in pairing adhesives and tapes that withstand extreme environments without compromising elasticity, cleanliness, or dielectric strength.

What makes Canyon Components a reliable partner for adhesives and tapes?

Canyon Components delivers a unified approach to bonding solutions by combining material expertise, testing, and supply-chain efficiency. We provide not only adhesives but also industrial-grade tapes designed for clean, efficient, and high-performance assembly. Our engineering support includes bonding design consultation, prototype testing, and custom die-cutting or packaging services for tape and adhesive products. Customers benefit from our ability to match adhesives and tapes to complex substrates such as fluoropolymers, metals, and elastomers. Whether you need a methacrylate for structural assembly, a PTFE-backed tape for chemical resistance, or a threadlocker for vibration protection, Canyon Components ensures every solution delivers consistency, compliance, and durability for your production environment. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!