Threadlocker Adhesives

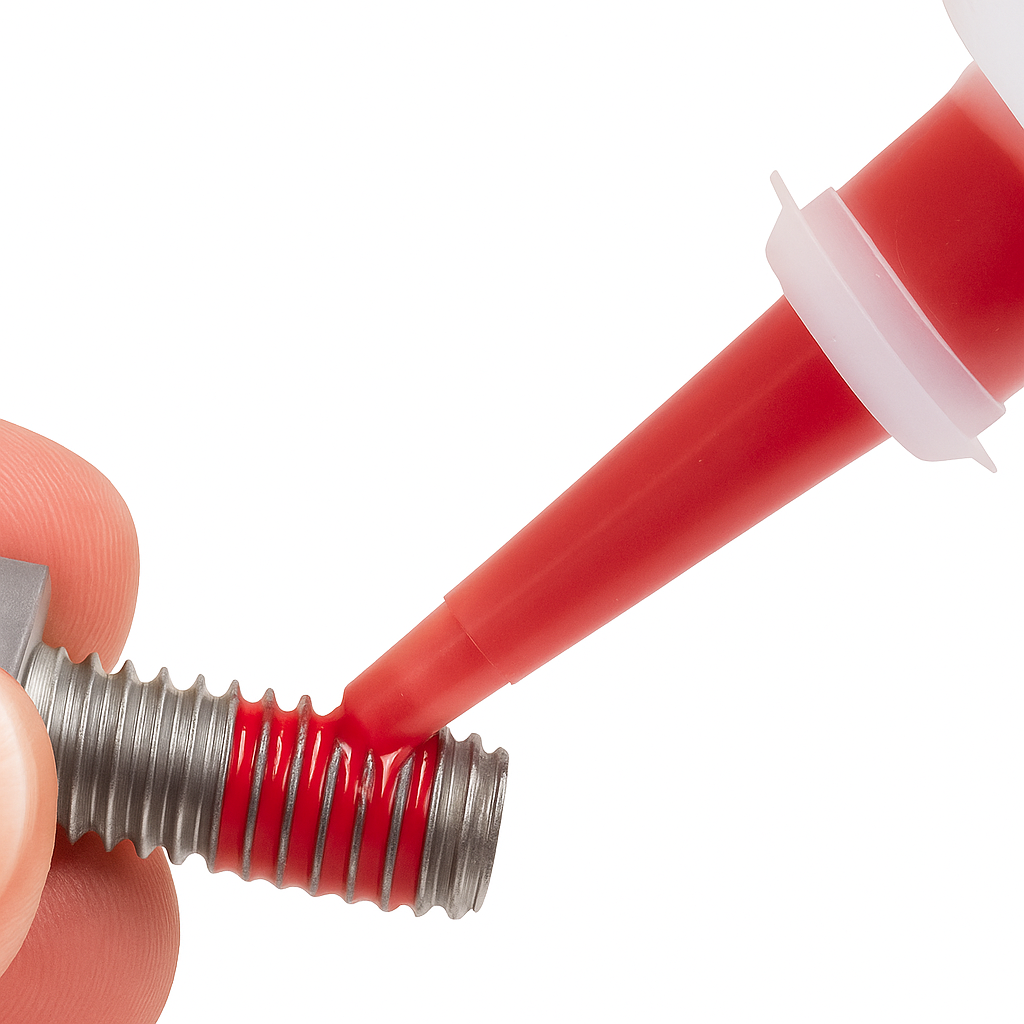

Threadlocker adhesives—also called anaerobic adhesives, bolt adhesives, or threadlocking compounds—are specialized bonding agents used to prevent threaded fasteners from loosening due to vibration, thermal expansion, or mechanical shock. These single-component adhesives cure in the absence of air and in the presence of metal ions, locking fasteners in place while sealing against leaks and corrosion.

Industry leaders like Loctite®, Permatex®, Vibra-Tite®, and 3M™ Scotch-Weld™ offer a wide range of threadlocking solutions suitable for both OEM and maintenance applications.

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Features of Threadlocker

Threadlockers offer several performance benefits tailored to mechanical assemblies:

- Variety of strengths: Available in low (removable), medium (serviceable), and high (permanent) strength formulations.

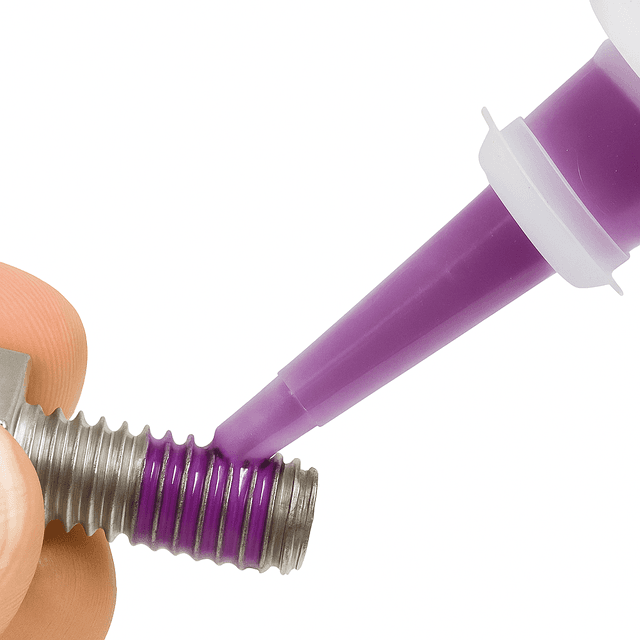

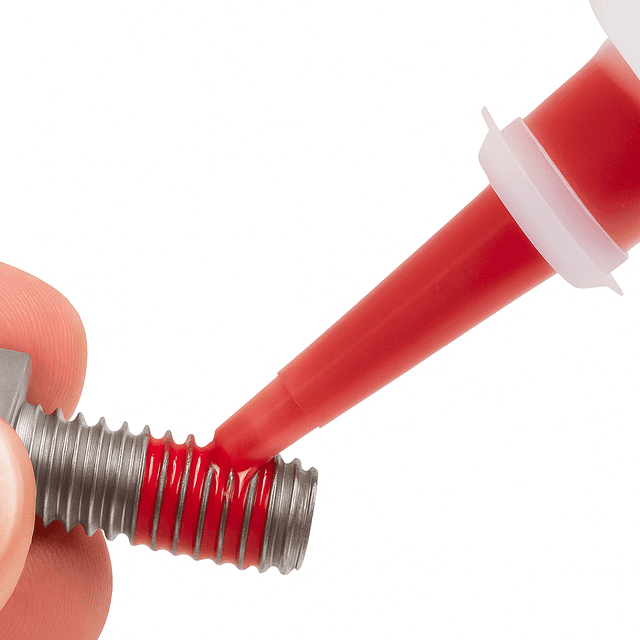

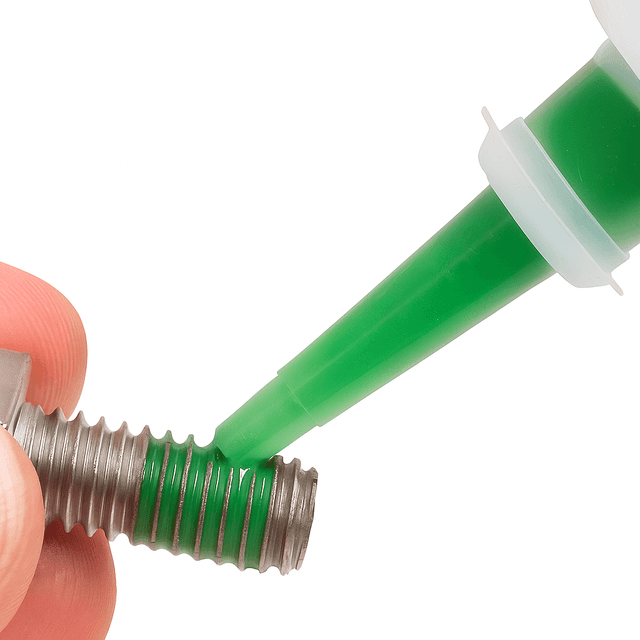

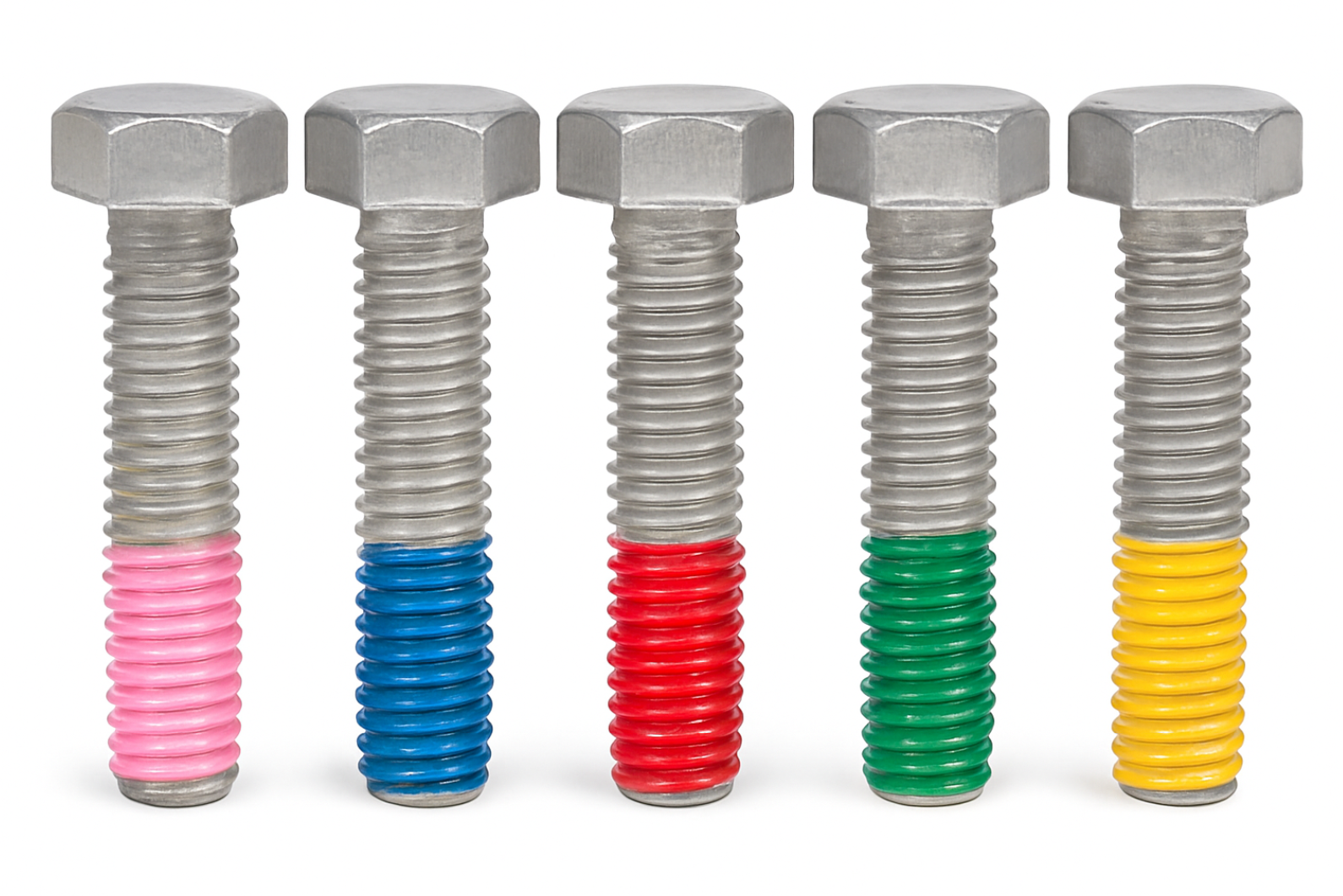

- Color-coded identification: Purple (low), Blue (medium), Red (high), Green (wicking).

- Anaerobic cure: Cures without oxygen when confined between metal surfaces.

- Vibration and shock resistance: Prevents loosening under dynamic load.

- Thermal resistance: Maintains integrity under fluctuating temperatures.

- Chemical resistance: Protects against oils, fuels, and solvents.

- Sealing properties: Helps prevent corrosion and fluid leaks.

Common Applications of Threadlockers

Threadlocker adhesives are widely used across industries that rely on secure fastener assemblies:

- Automotive and heavy truck: Engine bolts, transmission housing, and suspension components.

- Aerospace and defense: Vibration-prone fasteners, avionics, and fuel system seals.

- Industrial equipment: Motors, pumps, presses, compressors, and gearboxes.

- Electronics: Prevents fastener loosening from thermal cycling in circuit boards and casings.

- General manufacturing: Assembly lines, jigs, fixtures, and precision components.

We stock a wide range of industrial fastener adhesives and offer engineering support for product selection and dispensing system integration.

- Explore all adhesive products

- Request a Quote

- Contact Technical Support

Want to compare Loctite® 243 vs. 263? Need an NSF-certified Permatex® threadlocker for your facility? We’re here to help.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Threadlocker Strength Levels & Color Guide

Threadlockers are available in a range of strengths, each indicated by a standardized color code that reflects its holding power and disassembly method. Major manufacturers like Loctite, Permatex, 3M Scotch-Weld, and Vibra-Tite use these colors to simplify adhesive selection for both OEMs and maintenance teams.

Whether you're working on routine maintenance or high-performance manufacturing, selecting the right color-coded threadlocker ensures secure, reliable fastener performance with the appropriate ease of service or permanence.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect solution for your needs.

Purple – Low Strength

Strength: Easily removable. Ideal for: Small fasteners, adjustment screws, electronics. Use Cases: Eyewear, instrumentation, circuit board mounting. Removal: Standard hand tools.

Blue – Medium Strength

Strength: General-purpose, removable. Ideal For: Fasteners that require occasional disassembly. Use Cases: Pumps, gearboxes, appliance hardware. Removal: Hand tools; no heat needed.

Red – High Strength

Strength: Permanent locking. Ideal For: High-load or safety-critical applications. Use Cases: Automotive engines, heavy machinery, suspension components. Removal: Requires localized heat (~250°C / 480°F) and tools.

Green – Wicking Grade

Strength: Medium to high. Ideal For: Pre-assembled fasteners or tight spaces. Use Cases: Set screws, electrical connectors, sealed fasteners. Application: Applied after assembly; capillary action draws it in.

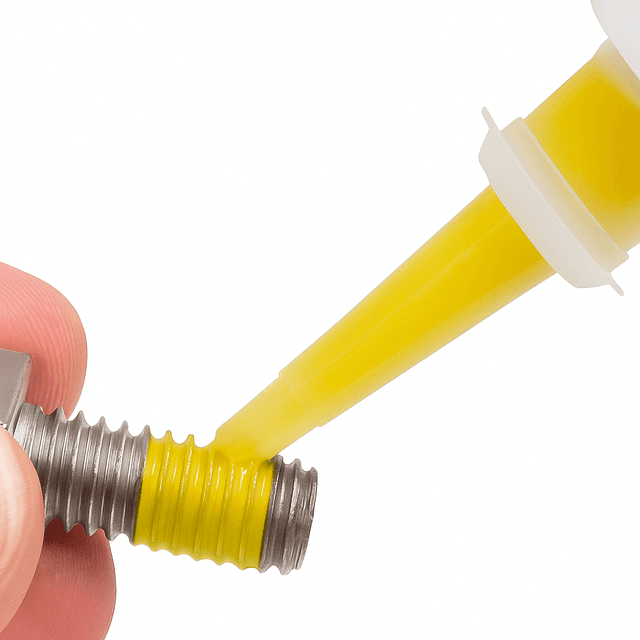

Yellow – Medium to High Strength (Specialty Grades)

Strength: Application-specific. Ideal For: Vibration-prone assemblies, specialty substrates, or industry-specific requirements. Use Cases: Aerospace hardware, high-vibration tooling, non-ferrous metals. Note: Yellow threadlockers are less common and often part of custom or niche formulations. Selection guidance may be needed.

Get a Quote Now!

Specialty Variants of Threadlocker

Modern threadlockers are engineered for specific requirements:

- Oil-tolerant grades: Ideal for fasteners that are pre-assembled or contaminated with oil.

- High-temperature threadlockers: Withstands service temperatures up to 232°C (450°F) or more.

- Wicking grades: Designed for use on already-assembled fasteners; capillary action allows penetration.

- Food-grade / NSF-certified: Safe for use in food and beverage equipment (e.g., Loctite® 2046).

- Removable threadlockers: Designed to balance holding power with ease of disassembly.

- Reusable / non-permanent: Low-strength formulas allow routine maintenance access.

These variants ensure compatibility with everything from mission-critical aerospace components to serviceable consumer goods.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect solution for your needs.

Pros and Cons of Threadlocker

If you're looking to improve fastener reliability, prevent unplanned maintenance, or enhance the durability of your assemblies, threadlocking adhesives offer a proven solution. They’re easy to apply in manual or automated setups, improve safety by preventing failures, and simplify your bill of materials by replacing multiple mechanical retention devices. Whether you're designing for automotive production, aerospace certification, or industrial reliability, there's a threadlocker formulation designed for your needs.

Color-coded and available in multiple strengths, they offer fast identification and easy integration into assembly line protocols or field repair kits. From high-strength permanent locking to precision low-strength formulations for delicate electronics, threadlockers ensure peace of mind in every threaded joint.

Pros of Threadlocker

- Prevents loosening caused by vibration and mechanical stress.

- Seals against moisture, corrosion, and leakage.

- Reduces need for mechanical locking devices (lock washers, nylon inserts).

- Improves reliability and lowers maintenance costs.

Cons of Threadlocker

- High-strength grades may require heat or tools for disassembly.

- Curing requires metal substrates and anaerobic (oxygen-free) conditions.

- Not suitable for large gaps or non-metallic fasteners without primer or activator.

Back to Adhesives Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More