Custom Part Request

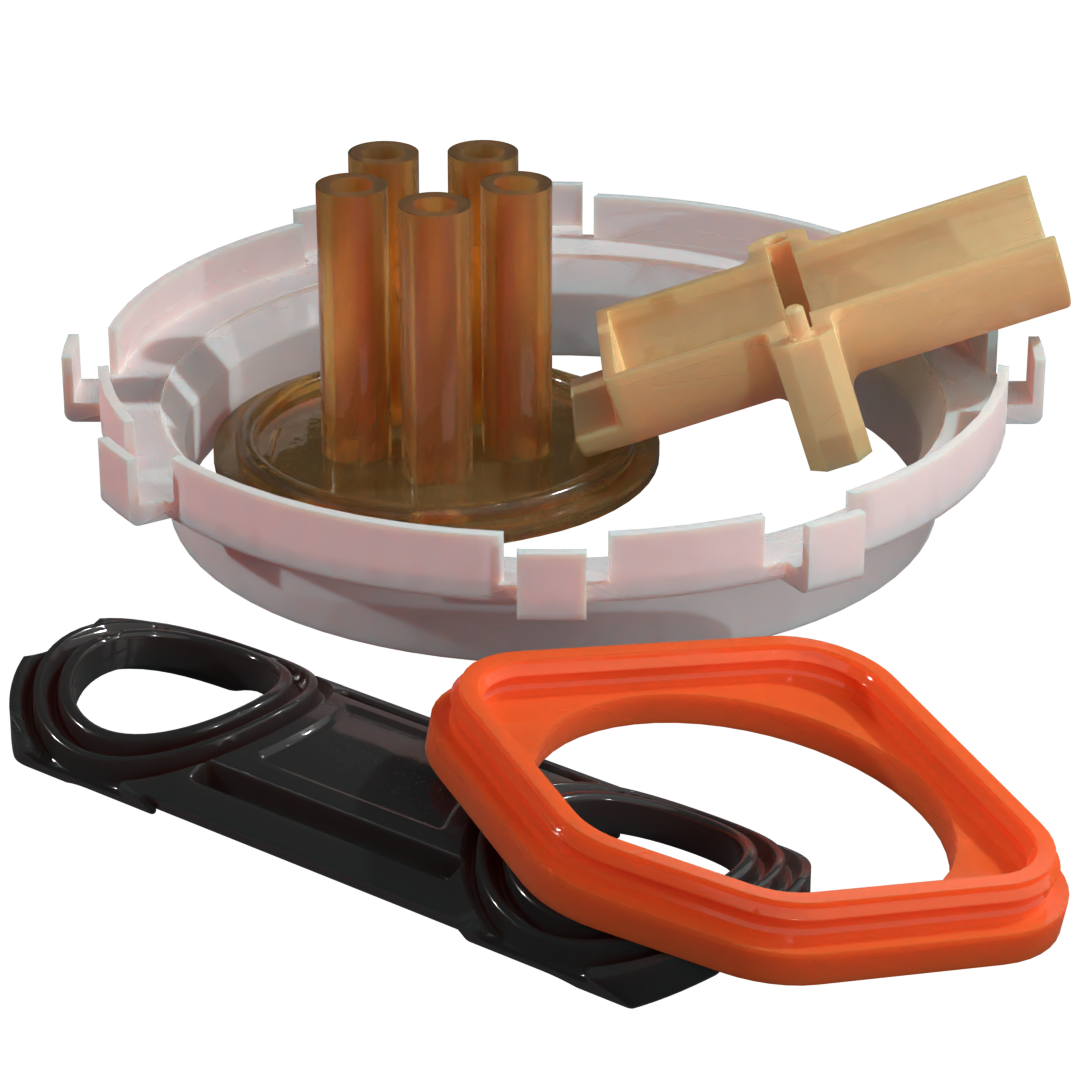

Welcome to our Custom Part Requests page, where your vision becomes reality. Whether you need metal, plastic, or rubber components, we specialize in creating high-quality custom parts tailored to your specific needs. Our expertise extends to a wide range of products, including gaskets, O-rings, seals, and much more. Our custom parts are used in a wide range of industries, including automotive, aerospace, manufacturing, and more. Whether you need durable gaskets for high-pressure environments, precision O-rings for sealing applications, or any other custom component, we have the expertise to deliver.

You can also reach us directly at Sales@CanyonComponents.com

DESCRIBE WHAT YOU NEED AND WE WILL GET BACK TO YOU AS SOON AS POSSIBLE

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Custom molded O-rings deliver precision sealing performance tailored to unique applications that standard sizes cannot address. They allow engineers to specify exact dimensions, durometer, and material properties to achieve optimal compression, chemical compatibility, and long-term durability. Canyon Components specializes in manufacturing O-rings from high-performance materials such as Kalrez®, Canrez®, Chemraz®, and Parker® compounds, as well as FFKM, FKM, EPDM, silicone, and NBR. Every O-ring is engineered to meet the specific requirements of industries like aerospace, chemical processing, semiconductor, and medical manufacturing, where reliability and certification are non-negotiable.

Which materials are best for custom molded O-rings?

Material selection depends on environmental conditions such as temperature, chemical exposure, and operating pressure. Canyon Components offers a wide range of compounds including FFKM for extreme chemical and temperature resistance, FKM for hydrocarbons and high heat, EPDM for water and steam, NBR for oils and fuels, and silicone for temperature flexibility. Specialty formulations like Aflas® for amine resistance or HNBR for ozone and abrasion resistance are also available. Each compound is tested for hardness, compression set, and elongation to ensure it meets both functional and regulatory requirements. Our team references Parker’s polymer classification system to ensure materials align with desired performance characteristics. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

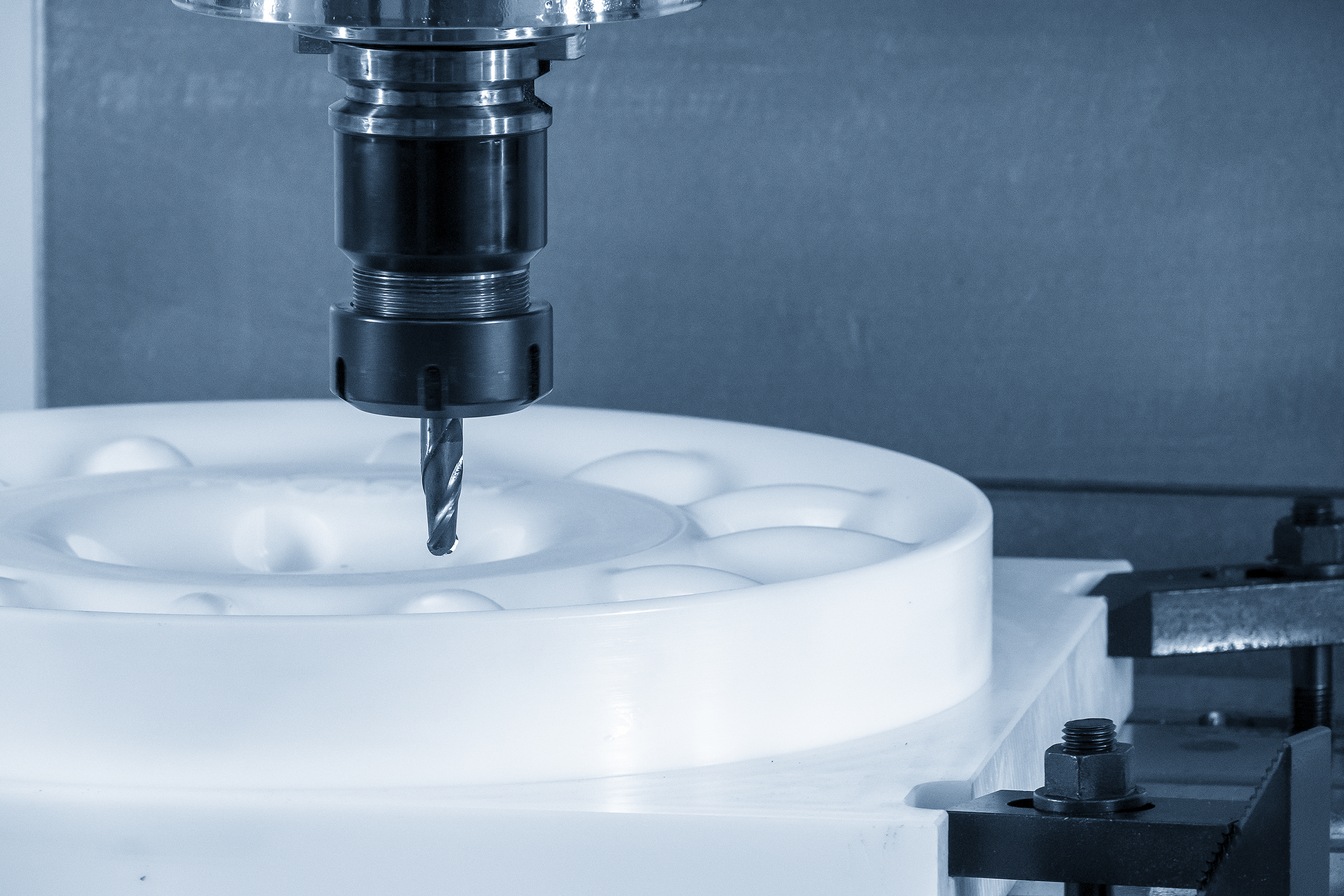

How are custom O-rings manufactured?

Custom O-rings are typically produced through compression, injection molding, continuous molding, and splice & vulcanization. In compression molding, uncured rubber is placed in a heated mold cavity, compressed under pressure, and cured to shape. Injection molding, on the other hand, uses automated machines to inject precise amounts of compound into the mold for high repeatability. Continuous molding, and splice & vulcanization both offer cost effective manufacturing methods for extremely large parts. Canyon Components employs these techniques depending on size, quantity, and tolerance requirements. After molding, parts undergo deflashing, inspection, and optional post-curing to enhance chemical resistance and remove residual volatiles. We also offer secondary processes such as coating, lubrication, and cleanroom packaging to meet customer-specific standards. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What tolerances can be achieved with custom molded O-rings?

Tolerances depend on material, size, and molding method. Standard elastomer tolerances generally follow RMA or ISO 3302 guidelines, but Canyon Components can achieve tighter tolerances through precision mold tooling and process control. Dimensional stability is maintained by monitoring mold temperature, curing cycles, and post-processing shrinkage. Our facility routinely produces O-rings for aerospace and semiconductor applications where dimensional variation must remain below a few thousandths of an inch, ensuring perfect fit and sealing integrity. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components manufacture O-rings in non-circular shapes?

Yes. While most O-rings are round, custom molding enables production of square, X-ring (quad), or complex profile designs. These specialized cross-sections offer unique benefits such as improved sealing efficiency, reduced friction, or increased stability under pressure. Canyon Components designs and molds non-standard geometries to fit specific gland configurations or performance requirements. For applications requiring enhanced extrusion resistance or sealing under dynamic motion, our engineers may recommend switching from a circular O-ring to a specialized profile like an X-ring or flat seal. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does durometer affect O-ring performance?

Durometer measures hardness and directly impacts how an O-ring behaves under compression. Softer O-rings (40–60 Shore A) conform better to surface irregularities, making them ideal for low-pressure or vacuum applications. Harder O-rings (80–95 Shore A) resist extrusion and deformation, performing better in high-pressure environments. Canyon Components helps customers determine the right balance between flexibility and extrusion resistance. Our manufacturing references the Parker durometer indicator system, ensuring precise matching between hardness and performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What testing and quality standards do Canyon Components’ O-rings meet?

Canyon Components produces O-rings to comply with a wide range of standards including ASTM D2000, MIL-SPEC, AMS, NORSOK M-710, and FDA CFR 21.177.2600. We perform compression set, tensile, and elongation testing on each batch to ensure consistency and reliability. For certain high-purity applications, such as semiconductor or medical manufacturing, we also conduct low-outgassing and particle contamination tests. Certificates of Conformance, batch traceability, and full material documentation are available with every order, ensuring transparency and compliance from formulation to final inspection. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are custom O-rings available for high-temperature or chemical exposure applications?

Yes. Canyon Components specializes in high-performance FFKM compounds such as Canrez®, Kalrez®, and Chemraz®, which resist aggressive solvents, acids, and amines at continuous service temperatures over 600°F. For applications with simultaneous chemical and thermal stress, FFKM offers the best combination of stability and elasticity. We also produce Viton®-based FKM O-rings for fuel and oil exposure over 400°F, and silicone-based compounds for extreme low-temperature flexibility in environments under -100°F. Our materials database includes cross-reference information for Parker, DuPont, and Greene Tweed formulations, helping customers find equivalent compounds that balance cost and performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide cleanroom-molded and packaged O-rings?

Yes. Cleanroom production is available for all customers and is commonly used in part production for industries such as semiconductor, pharmaceutical, and biotechnology manufacturing. O-rings molded in clean environments are washed, inspected, and vacuum-sealed to eliminate particulates or surface residues. Canyon Components offers cleanroom packaging options, along with nitrogen-purged or moisture-barrier bags. This ensures contamination-free components ready for use in high-purity or vacuum-critical systems where even microscopic debris could compromise performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a reliable partner for custom molded O-rings?

Canyon Components combines material science expertise, precision tooling, and responsive service to deliver O-rings that meet the highest performance standards. Our engineers work with customers through every phase of production, from design and material selection to prototype testing and full-scale manufacturing. By maintaining close control over compounding, molding, and inspection, we ensure dimensional accuracy and consistent sealing properties across batches. Whether you need a single prototype or a recurring production order, Canyon Components provides short lead times, technical guidance, and comprehensive documentation that make us a trusted partner for sealing solutions in every industry.