Reference Hub

The Reference Hub is your ultimate resource for all things related to O-rings, rubbers, plastics, metals, materials, and engineering insights. It houses an extensive collection of guides, including O-ring groove design, material comparisons, and chemical compatibility data, empowering engineers to make informed decisions. Groove design calculators streamline complex tasks, while a diverse range of blog posts keeps you updated on industry trends.

Whether you're designing seals, selecting materials, or seeking expert advice, this hub is your one-stop destination for valuable tools and knowledge, facilitating excellence in engineering and materials science. Explore, learn, and optimize your projects with the Reference Hub.

The engineers and consultants here at Canyon Components take pride in finding the perfect solution our customer’s needs. Contact our expert staff for assistance with any seal or application questions!

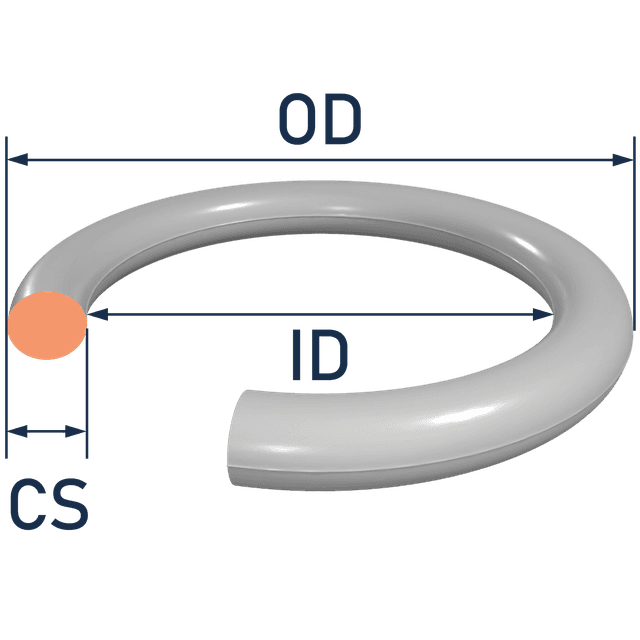

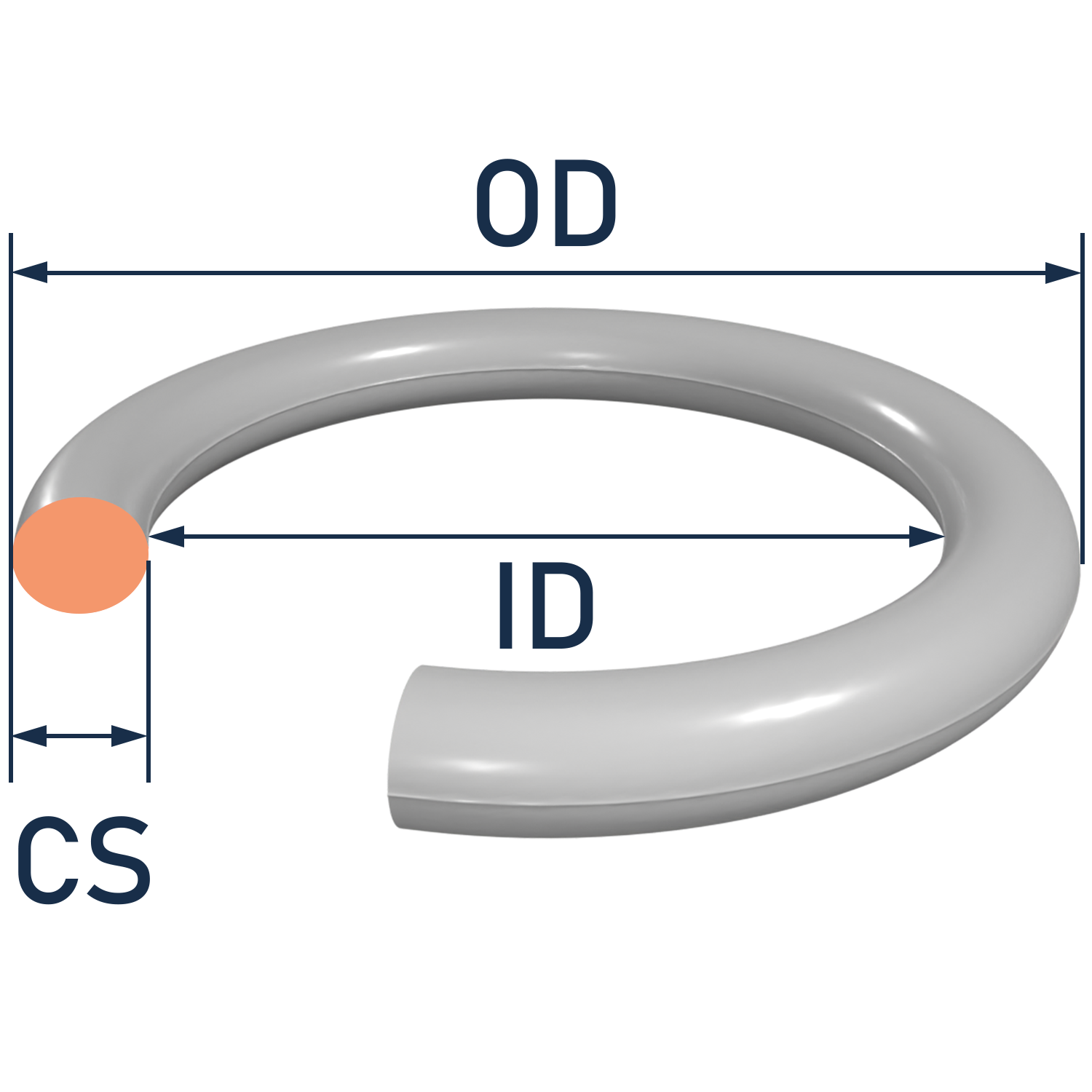

Standard O-ring Dimensions

USA AS568 O-ring Sizing Chart

USA AS568 O-rings are standardized sealing rings used extensively in hydraulic and pneumatic systems. They come in various sizes, materials, and hardness levels, ensuring reliable sealing and fluid containment in diverse industrial applications.

Japanese JIS O-ring Sizing Chart

JIS O-rings adhere to Japanese Industrial Standards, offering consistent sealing solutions. These standardized O-rings come in a range of sizes and materials, ensuring precise and reliable sealing in machinery and equipment across various industries.

Metric O-Ring Sizing Chart

Explore metric O-rings, designed to meet international standards for sealing in various industries. Learn about their features, applications, and how they ensure reliable performance in metric-based systems.

Custom O-ring Sizing

Custom-sized O-rings are tailored sealing solutions, crafted to exact specifications for specialized applications. These made-to-order O-rings ensure a precise fit, optimal sealing, and resilience in diverse industrial and engineering settings, meeting unique requirements with precision.

Parker Series 5-XXX O-Ring Sizes

Explore the Parker Series 5-XXX O-ring sizes, with detailed dimensions for a range of sealing applications. Find the right size for your needs and learn about the series specifications and uses in various industries.

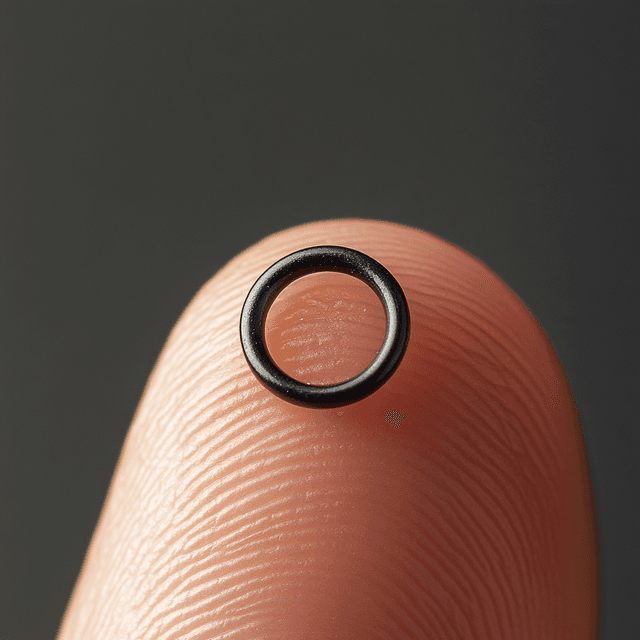

Micro O-rings

Learn about micro O-rings, precision-engineered for small-scale sealing applications in industries like electronics, medical devices, and aerospace. Discover their features, common uses, and advantages in high-precision environments.

Compliances, Standards, & Tolerances

Compliance Hub

Explore our Compliance Hub, summarizing key industry standards and certifications including FDA, NSF, WRAS, NORSOK, and more. Learn how our materials and products meet stringent regulations for various applications in food, medical, and industrial sectors.

ASTM D2000 Elastomeric Materials

Explore ASTM D2000 elastomeric materials, designed to meet industry standards for performance and durability. Learn about their features, classifications, and how they provide reliable sealing in various industrial environments.

O-Ring Rubber Shelf Life

Learn about the shelf life of O-ring rubber materials, factors affecting longevity, and best storage practices to maintain sealing performance. Ensure your O-rings stay reliable and effective over time.

RMA Tolerances for O-Rings, Molded Parts, and Extruded Parts

Learn about tolerance standards for O-rings, molded, and extruded parts according to RMA guidelines. Discover how these standards ensure precision and reliability across various sealing and industrial applications.

Common O-Ring Failures

Learn about common O-ring failures, including causes like abrasion, extrusion, and chemical degradation. Discover effective solutions and prevention methods to extend O-ring life and ensure reliable sealing performance.

O-ring Groove Design Tables

General O-ring Groove Design Guide

The O-ring general groove design guide is a comprehensive reference for engineers and designers. It offers versatile guidelines and recommendations for creating grooves that accommodate O-ring seals in various applications, ensuring effective sealing and preventing leaks.

Face Seal Groove Design Guide

The O-ring face seal groove design guide is an essential resource for engineers. It offers detailed instructions and best practices for designing grooves that accommodate O-ring face seals, ensuring effective sealing in hydraulic and pneumatic systems, reducing the risk of leaks and system failures.

Dove Tail Seal Groove Design Guide

The O-ring dovetail seal groove design guide is a comprehensive resource for engineers. It provides insights and recommendations for creating secure and precise dovetail grooves to accommodate O-ring seals, ensuring reliable sealing performance in critical applications.

Static Piston & Rod Seal Groove Design Guide

The O-ring static rod and piston seal groove design guide is an essential tool for engineers. It offers expert guidance on designing grooves for O-ring seals in static applications, ensuring effective sealing and preventing leaks in hydraulic and pneumatic systems.

Dynamic Piston & Rod Seal Groove Design Guide

The O-ring dynamic rod and piston seal groove design guide is an essential tool for engineers. It offers expert guidance on designing grooves for O-ring seals in dynamic applications, ensuring effective sealing and preventing leaks in hydraulic and pneumatic systems.

Dynamic Rotary Seal Groove Design Guide

The O-ring dynamic rotary seal groove design guide is a useful resource for engineers. It provides detailed instructions for creating grooves to accommodate O-ring seals in dynamic rotary applications, ensuring efficient sealing and minimizing wear in rotating equipment.

Miscellaneous Reference Material

ISO 9001 Certification

As a leader in our industry, Canyon Components LLC proudly uphold the highest standards of quality and efficiency, a commitment encapsulated in our achievement of ISO 9001 certification.

Elastomeric Material Comparison

The elastomeric material comparison page is a valuable resource for professionals. It allows users to compare and contrast different elastomer materials, providing insights into their properties, applications, and suitability for specific industrial and engineering needs, aiding informed material selection.

Chemical Compatibility Guide

The chemical compatibility page is an essential tool for engineers and chemists. It provides detailed information on how various elastomer materials interact with different chemicals, helping ensure compatibility in industrial applications and preventing material degradation.

Permeability of Elastomers and Plastics

Learn about the permeability of elastomers and plastics, including factors that impact gas and liquid transmission rates. Discover how material permeability affects sealing performance in various industrial applications.

Blog Posts

The Canyon Components blog is a knowledge-rich platform. It features insightful articles, industry updates, and expert opinions on materials science, engineering, and applications. A valuable resource for professionals seeking in-depth insights and the latest trends in the field.

Line Card

Canyon Components' line card showcases a comprehensive range of products, including O-rings, gaskets, plastics, and metals. It provides a quick reference guide for professionals, offering a glimpse into the diverse materials available to meet various industrial and engineering needs.

Glossary of Seal & Rubber Terms

Explore our comprehensive glossary of terms related to seals, rubber materials, and elastomeric components. This guide provides clear definitions and explanations to help you better understand the technical language used in the sealing industry.

Glossary of Specifications

Explore our Glossary of Specifications, offering clear definitions and explanations of key industry standards and certifications. Learn how these specifications impact material selection and compliance in various industries.

AS568 to European O-Ring Size Cross Reference

Find AS568 to European O-ring size cross references, helping you match U.S. standard sizes with European equivalents. Ensure compatibility across global applications with our detailed sizing guide.

Customer Information Packet: Compliance and Documentation (REACH, RoHS, W9, and More)

Access essential compliance documents and certifications, including REACH, RoHS, W9, and others. Our customer information packet provides all necessary details to ensure regulatory compliance and streamlined onboarding.

Common O-Ring Failures

Learn about common O-ring failures, including causes like abrasion, extrusion, and chemical degradation. Discover effective solutions and prevention methods to extend O-ring life and ensure reliable sealing performance.

All Products

Explore our full range of products, including gaskets, O-rings, screws, custom parts, and more. Discover high-quality components designed to meet the needs of various industrial applications.

O-ring Groove Design Calculators

O-Ring Face Seal Groove Calculator

The O-ring Face Seal Groove Calculator is a valuable tool for engineers and designers. It assists in determining the optimal dimensions of O-ring grooves, ensuring proper fit and sealing performance in machinery and equipment, streamlining the design process and preventing leaks.

O-ring Rod Seal Groove Calculator

The O-ring Rod Seal Groove Calculator is a valuable tool for engineers and designers. It assists in determining the optimal dimensions of O-ring grooves, ensuring proper fit and sealing performance in machinery and equipment, streamlining the design process and preventing leaks.

O-ring Piston Seal Groove Calculator

The O-ring Piston Seal Groove Calculator is a valuable tool for engineers and designers. It assists in determining the optimal dimensions of O-ring grooves, ensuring proper fit and sealing performance in machinery and equipment, streamlining the design process and preventing leaks.

O-ring Rotary Seal Groove Calculator

The O-ring Rotary Seal Groove Calculator is a valuable tool for engineers and designers. It assists in determining the optimal dimensions of O-ring grooves, ensuring proper fit and sealing performance in machinery and equipment, streamlining the design process and preventing leaks.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

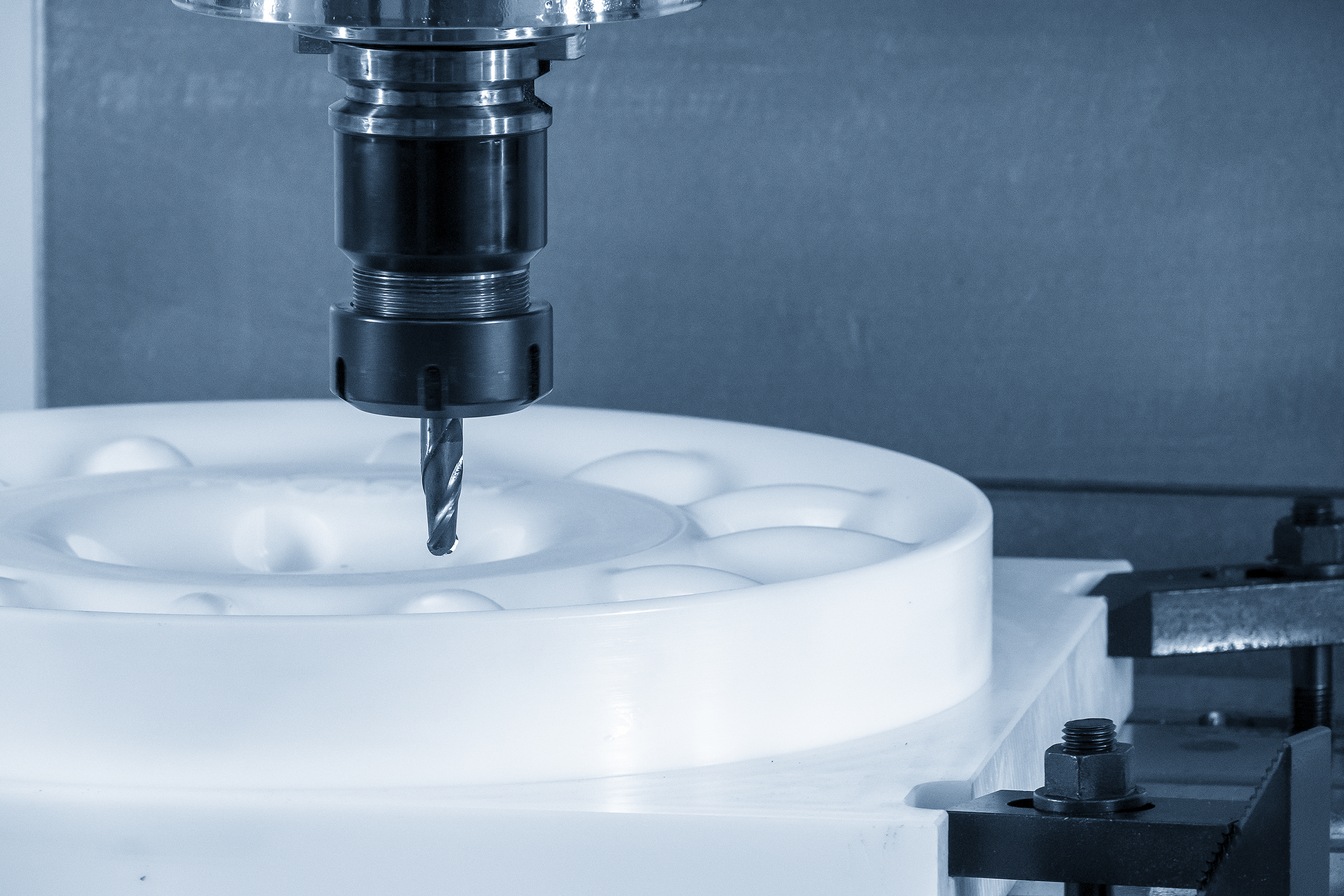

Custom Parts & Custom O-rings

Learn More

FAQ

O-rings and seals are fundamental to reliable performance in virtually every industry. Whether you are designing a new groove assembly or selecting replacement materials, precision in dimension, material compatibility, and hardness is key. Canyon Components provides extensive O-ring and seal reference resources, including AS568 standard sizing, custom groove design guidance, and material equivalency charts across major brands like Kalrez®, Canrez®, Chemraz®, and Parker®. Our engineering team can help you optimize your sealing solution, from prototype design to full production.

How do I choose the right O-ring material?

Material selection depends on chemical exposure, temperature, pressure, and motion type. FKM offers broad chemical resistance and high temperature stability. EPDM performs well with water, steam, and polar fluids. Silicone excels in extreme temperature ranges. NBR provides excellent fuel and oil resistance, and FFKM offers the highest chemical and thermal performance available. Canyon Components’ material comparison charts help identify the best compound for your environment and sealing requirements. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are AS568 O-ring sizes, and why are they important?

AS568 is a standard sizing system established by the SAE for O-rings used in the United States. It defines cross-sections and inside diameters to ensure compatibility across manufacturers. Using standard AS568 sizes simplifies design, reduces lead time, and ensures availability. Canyon Components provides AS568 size charts and cross-reference tools to match existing specifications or identify equivalent sizes in metric or custom systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide custom-sized O-rings or seals?

Yes. We offer custom-molded, spliced, and extruded O-rings and seals in virtually any dimension or cross-sectional geometry. Whether you require large-diameter spliced rings, precision micro seals, or non-circular profiles, our manufacturing capabilities support both prototype and production runs. Our engineering team ensures dimensional accuracy, proper durometer selection, and material certification to meet your application’s needs. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do I find an equivalent material for Kalrez®, Chemraz®, or Parker® compounds?

Canyon Components maintains extensive brand equivalency data to help customers find high-performance alternatives. Our Canrez® FFKM compounds are designed to match or exceed the performance of Kalrez® and Chemraz® materials in high-temperature and chemically aggressive environments. We can also cross-reference Parker® materials to provide options that maintain sealing reliability while offering improved availability and pricing. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What testing or validation methods are used for O-ring materials?

O-ring compounds are tested to ensure performance under specific conditions. Typical testing includes compression set, tensile strength, elongation, and hardness measurements, as well as resistance to heat, fluids, and pressure cycling. Canyon Components also conducts ASTM and ISO testing, and can provide traceable certification for aerospace, medical, and industrial requirements. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What causes O-ring failure, and how can it be prevented?

Common causes of O-ring failure include compression set, extrusion, chemical attack, thermal degradation, and improper installation. See our page deep diving into O-Ring Failures. Preventing failure involves proper groove design, correct material choice, adequate lubrication, and attention to installation techniques. Canyon Components’ engineers can analyze failed seals and recommend design or material improvements to extend service life and reduce downtime. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the main differences between static and dynamic seals?

Static seals are used in assemblies where the mating surfaces do not move relative to each other, such as pipe flanges or covers. Dynamic seals operate in applications with motion, such as pistons or rotating shafts, and therefore require materials and lubricants that resist friction and wear. Canyon Components provides both static and dynamic sealing solutions, including low-friction coatings and specialty elastomer blends to improve performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components assist with reverse engineering or replacement parts?

Yes. Our team provides reverse engineering services to identify existing O-ring or seal dimensions, material type, and hardness. Using FTIR analysis, durometer testing, and dimensional scanning, we can reproduce legacy parts or improve upon them with upgraded materials. This service is ideal for obsolete components or equipment that requires exact replacement parts to maintain function. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Does Canyon Components support documentation and compliance requirements?

Absolutely. We can provide full documentation packages, including material certifications, batch traceability, and compliance reports for standards such as FDA CFR 21.177.2600, USP Class VI, NSF 61, and NORSOK M-710. Whether you need materials for aerospace, semiconductor, or sanitary applications, Canyon Components ensures all parts meet regulatory and performance standards. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a reliable partner for O-ring and seal design?

Canyon Components combines technical expertise with extensive material knowledge and manufacturing flexibility. We supply both standard and custom O-rings across a wide range of compounds, durometers, and geometries. Beyond products, our value lies in design assistance, testing support, and quick turnaround. Customers can depend on our engineering-driven approach to deliver reliable sealing solutions for even the most complex systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!