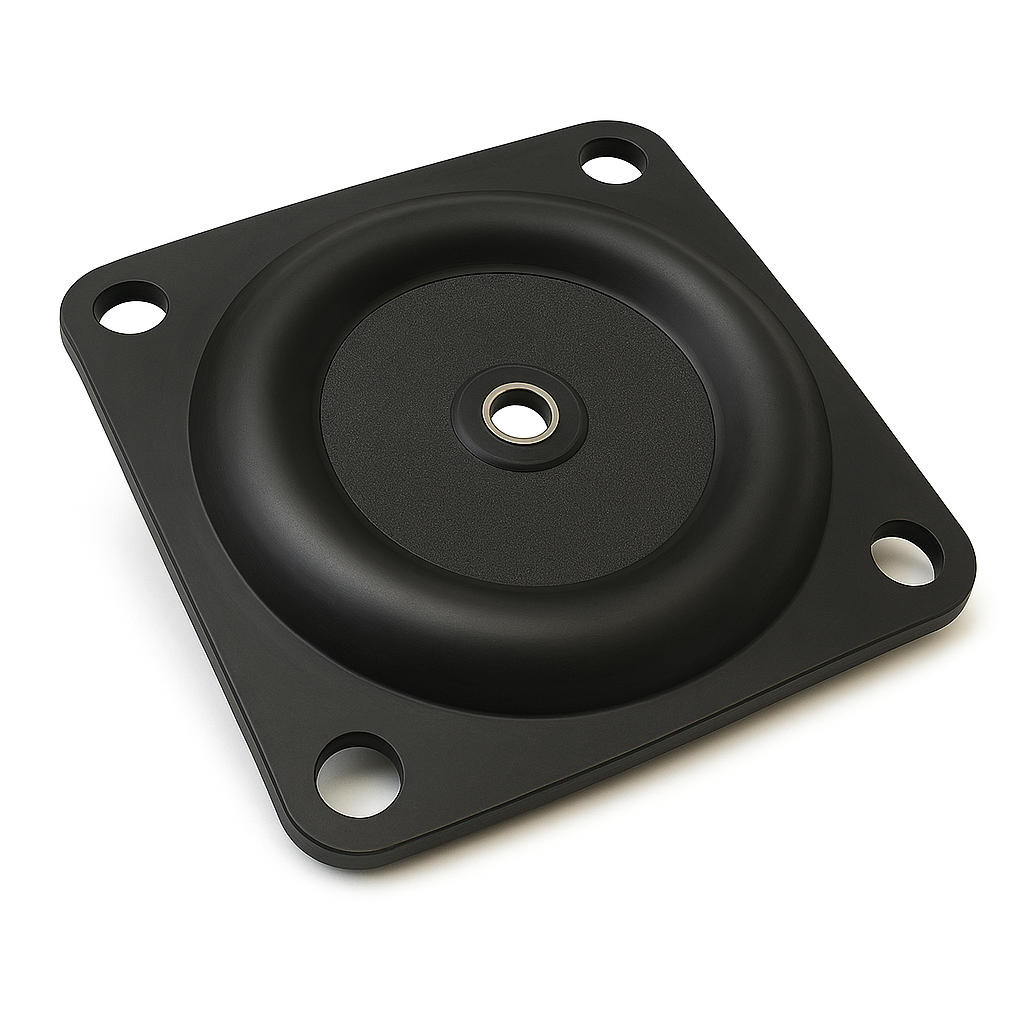

Fabric Reinforced Diaphragms

Canyon Components specializes in custom-designed fabric reinforced diaphragms, engineered specifically for applications in actuators, controls, regulators, valves, pumps, and accumulators. Our diaphragms can be precisely die-cut, formed from rubber-coated fabric, or insert molded with fabric reinforcement, depending on your unique requirements. We also offer diaphragms molded with metal inserts, and optional PTFE coatings for enhanced chemical resistance and reduced friction.

Our advanced material laboratory is fully equipped with TGA, IR, DSC, and DTMA analytical equipment, allowing precise material selection, development, and stringent quality control. Certifications are available to demonstrate compliance with international standards such as FDA, WRAS (formerly WRC), ECE R67 / 110, and EN 549.

Learn more about our full capabilities on our elastomer diaphragms page, or request a quote today.

Features of Fabric Reinforced Diaphragms

- Custom Engineering: All diaphragms are custom-engineered specifically for your application's demands—no standard off-the-shelf range.

- Fabric Reinforcement: Enhanced strength, pressure resistance, and durability through embedded fabric inserts such as polyamide (Nylon), polyester (Dacron), aramid fiber (Nomex), or glass fiber.

- Metal and Thermoplastic Inserts: Options include aluminum, steel, and high-performance thermoplastics (glass-filled Nylon, PPS, and PEEK), providing dimensional stability and structural strength.

- PTFE Coatings: Diaphragms available with bonded PTFE coatings to enhance chemical resistance, reduce friction, and extend service life.

- Bonded Flange Gaskets: Diaphragms can be supplied pre-bonded to various flange gasket materials, simplifying installation and improving sealing reliability.

Visit our comprehensive diaphragms materials and features page or request a quote.

Common Applications for Fabric Reinforced Diaphragms

- Actuators and Control Systems: Precisely control and regulate fluid flow, pressure, and mechanical movements.

- Valves and Regulators: Consistently reliable sealing in flow control and pressure management applications.

- Pumps and Accumulators: Efficiently handle pulsating pressures and continuous cycle operation in fluid-handling equipment.

- Automotive and Aerospace: Fuel system components, emission control equipment, and fluid management solutions requiring durability and consistent performance.

- Medical and Pharmaceutical: Compliance with FDA and other international medical standards ensures safety in critical patient-contact applications.

Learn more about application-specific diaphragm solutions at our diaphragms applications page, or request a quote directly.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Available Elastomer and Fabric Materials

Elastomers include:

- FFKM (Perfluoroelastomer, Canrez®, Kalrez®, Chemraz®)

- FKM, type A, GF, GLT, GFLT, ETP, etc. (fluorocarbon, Viton®)

- VMQ (silicone)

- FVMQ (fluorosilicone)

- EPDM (ethylene propylene diene monomer)

- ECO (epichlorohydrin)

- NBR (nitrile, buna-N)

- HNBR (hydrogenated nitrile, e.g. Therban®)

- CR (chloroprene, Neoprene®)

Fabrics and textile inserts include:

- Polyamide (Nylon)

- Polyester (Dacron)

- Aramid fiber (Nomex)

- Glass fiber

Explore more about diaphragm materials on our dedicated elastomer diaphragms materials page, or request a quote for customized solutions.

Specialty Variants

To further meet specialized needs, Canyon Components offers:

- Metal Insert Diaphragms: Molded-in metal inserts including aluminum and steel for enhanced structural support.

- Thermoplastic Insert Diaphragms: Glass-filled Nylon, PPS, and PEEK inserts for applications needing superior dimensional stability and mechanical strength.

- PTFE-Coated Diaphragms: Chemically inert PTFE coatings for demanding chemical environments and reduced friction operation.

- Diaphragm-Flange Gasket Combinations: Diaphragms supplied pre-bonded to compatible flange gasket materials to streamline assembly and ensure reliability.

Fiber reinforced diaphragms are particularly advantageous in low-pressure applications, effectively eliminating "ballooning" and providing outstanding dimensional stability. Additionally, they can be combined with traditional fabric reinforced diaphragms for extremely high-pressure applications, significantly enhancing diaphragm strength and reducing the risk of blow-through.

Key Benefits of Fiber Reinforced Diaphragms:

- Eliminates ballooning in low-pressure scenarios

- Outstanding gasketing performance due to low compression set

- Capable of being manufactured in thin profiles for high sensitivity

- Superior strength, consistency, and repeatability versus homogeneous diaphragms

- Extended stroke-to-bore ratios exceeding the typical 1:1 limit associated with traditional fabric-reinforced diaphragms

Request a quote for your specialty fabric reinforced diaphragm today.

Get a Quote Now!

Pros and Cons of Fabric Reinforced Diaphragms

Canyon Components provides comprehensive design and manufacturing expertise in custom-engineered, fabric reinforced diaphragms. Our state-of-the-art lab equipment (TGA, IR, DSC, DTMA) ensures precise material analysis, quality control, and compliance with rigorous industry standards.

With flexible material combinations, expert guidance, and reliable delivery timelines, Canyon Components delivers solutions matching or exceeding leading diaphragm manufacturers like Diacom and Trelleborg. Trust us to provide durable, high-performance diaphragms tailored specifically to your application requirements.

Ready to start your diaphragm project? Visit our detailed elastomer diaphragms page, or quickly request a quote.

Pros of 3D Printed PEEK Parts

- Superior pressure and tear resistance through fabric reinforcement

- Customization flexibility (elastomers, fabrics, coatings, inserts)

- Compliance with industry-specific standards (FDA, WRAS, ECE R67/110, EN 549)

- Reliable sealing performance and long service life

Cons of Fabric Reinforced Diaphragms

- Typically higher initial cost compared to simpler diaphragm designs

- Specialized materials and configurations may extend manufacturing lead times

- Limited flexibility for extremely intricate shapes due to embedded inserts

For further insights into diaphragm advantages, visit our diaphragms features page or request a quote.

Back to Plastics Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More