EMI & RFI Shielding Materials

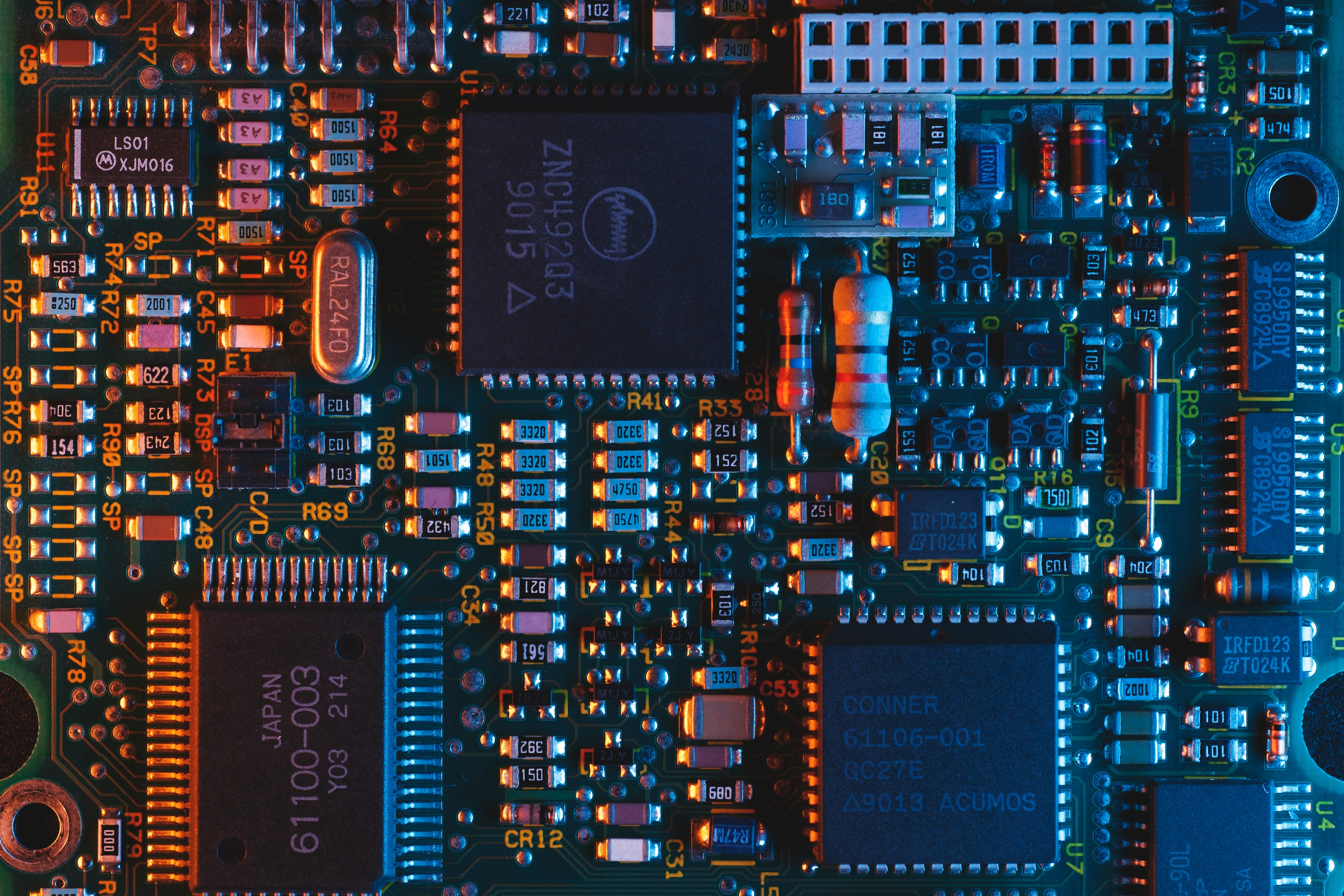

In an increasingly connected world, electromagnetic interference (EMI) and radio-frequency interference (RFI) can disrupt the functionality of electronic devices and systems. EMI & RFI shielding materials are designed to mitigate these interferences, ensuring electromagnetic compatibility (EMC). In this web page, we will explore the significance of EMI & RFI shielding materials, common application considerations, and discuss different types used in various industries.

The CanGuard™ line of materials, O-rings, gaskets, & custom molded parts are at the leading edge of shielding polymer technology. Proven in the field year after year, CanGuard™ materials O-rings, gaskets, & custom molded parts have been developed to offer superior sealing solutions with enhanced electromagnetic interference (EMI) shielding and radio frequency interference (RFI) shielding.

With Canyon Components, you can be sure that high quality materials that meet you needs are always readily available. Custom & standard EMI & RFI Shielding Materials available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

EMI & RFI Shielding Materials Available

Thousands of EMI & RFI Shielding Materials are available now with Canyon Components! Some common EMI & RFI Shielding Materials include the following.

EMI & RFI Shielding Materials Available

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

What are EMI & RFI Shielding Materials?

- EMI & RFI shielding materials are substances, coatings, or components engineered to block or absorb electromagnetic and radio-frequency signals, preventing unwanted interference with electronic devices. These materials are critical for maintaining the reliability and performance of sensitive electronic systems.

Common Considerations

- Frequency Range: Materials must be selected based on the specific frequency range of the interference to be shielded. Different materials are effective at different frequencies.

- Shielding Effectiveness: The shielding effectiveness of materials, measured in decibels (dB), determines their ability to attenuate or block electromagnetic and radio-frequency signals.

- Material Form: EMI & RFI shielding materials are available in various forms, including specialty elastomer blends, foils, conductive paints, gaskets, and enclosures. The choice depends on the application and installation requirements.

- Environmental Conditions: Consider the environmental conditions, such as temperature, humidity, and exposure to chemicals, to ensure that the selected materials remain effective over time.

- Regulatory Compliance: Materials should comply with industry standards and regulations, such as MIL-DTL-83528 for military applications or FCC regulations for consumer electronics.

- Integration with Design: The integration of shielding materials into the design of electronic devices or enclosures is crucial to achieving optimal EMI & RFI performance.

Material Options

- Conductive Gaskets and Seals: Conductive gaskets and seals are used to create a conductive seal between mating surfaces, providing EMI & RFI protection in enclosures.

- Conductive Foils: Conductive foils made of materials like copper or aluminum are used to create effective shields within enclosures or on the surfaces of electronic devices.

- Conductive Paints and Coatings: Conductive paints and coatings contain metallic particles and can be applied directly to surfaces to create shielding layers.

- Conductive Fabrics and Tapes: Conductive fabrics and tapes are flexible materials that can be used to wrap or cover sensitive components or cables.

- Shielded Enclosures: Entire enclosures can be designed to act as shields, offering complete protection for electronic equipment.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Electronics EMI & RFI Shielding

EMI and RFI Shielding Materials

Explore CanGuard EMI & RFI Shielding materials, designed to protect electronics from interference and ensure reliable performance in sensitive applications.

Vacuum Baking & Cleaning

Explore our specialized services: vacuum baking for material degassing, ultrasonic cleaning for precision parts, and custom bagging for product protection. Request a quote today!

Clean Room Manufactured Materials

Discover clean room manufactured material features, applications, and how they meet strict cleanliness standards in medical, pharmaceutical, and semiconductor environments.

EMI & RFI Shielding Materials Available

Click here to see some of our most commonly served industries!

Each of these materials has its own advantages, limitations, and cost implications. The choice of material usually depends on factors like chemical compatibility, temperature, pressure, dynamic or static use, and specification requirements.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Industries Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Electromagnetic interference (EMI) and radio frequency interference (RFI) can disrupt sensitive electronics, compromise communication systems, and degrade equipment performance in critical environments. Effective shielding requires precision materials that combine electrical conductivity with strong environmental sealing properties. Canyon Components’ CanGuard EMI and RFI shielding line provides O-rings, gaskets, and custom components engineered from conductive elastomers and plastics that block unwanted interference while maintaining sealing integrity against dust, moisture, and vibration. Our products are available in silicone, fluorosilicone, EPDM, and metal-filled conductive compounds, suitable for aerospace, defense, telecom, and electronic applications where both electrical continuity and environmental protection are essential. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What materials are used in conductive EMI and RFI shielding seals?

Conductive elastomers are silicone or fluorosilicone bases loaded with fine metal particles to create a flexible, conductive path. Common fillers include silver-aluminum, silver-copper, nickel-graphite, silver-glass, and pure silver, each selected for specific conductivity and corrosion resistance requirements. For environments exposed to fuel, oil, or solvents, fluorosilicone-based conductive compounds are preferred. Canyon Components also provides conductive thermoplastics and fabric-reinforced gaskets for lightweight applications. Every compound is engineered to achieve a balance between electrical conductivity, mechanical resilience, and environmental sealing, ensuring that the gasket or O-ring performs reliably even under vibration, temperature cycling, and humidity. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components’ CanGuard product line differ from standard conductive seals?

The CanGuard series is designed to deliver consistent performance across a wide range of environmental and electromagnetic conditions. Each formulation undergoes testing for volume resistivity, shielding effectiveness, compression set, and environmental exposure to verify long-term stability. CanGuard materials maintain their conductive properties even after repeated compression cycles, minimizing contact resistance between mating surfaces. Canyon Components also tailors compound formulations to meet MIL-DTL-83528, ASTM, & SAE AMS specifications, ensuring compatibility with aerospace and defense requirements. Beyond standard sizes, we offer custom extrusions, molded shapes, and overmolded components, providing complete integration between EMI protection and mechanical sealing. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What is the difference between conductive silicone and conductive fluorosilicone?

Conductive silicone is ideal for general-purpose EMI and RFI shielding in enclosures and housings that are not exposed to harsh fluids. It provides excellent flexibility, temperature resistance, and low compression set. Conductive fluorosilicone, on the other hand, is formulated for environments where fuels, hydraulic fluids, and solvents are present, such as aircraft, defense systems, and industrial electronics. Canyon Components supplies both materials with a range of conductive fillers that achieve surface resistivities as low as 0.004 ohm-cm. Our engineers help customers determine whether the chemical compatibility of fluorosilicone or the broader temperature tolerance of silicone best suits the intended environment. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How are EMI and RFI shielding gaskets tested for performance?

Shielding gaskets are tested for shielding effectiveness in decibels (dB), measuring their ability to attenuate electromagnetic signals across specific frequency ranges. Tests often follow methods such as MIL-DTL-83528 depending on the application. Canyon Components evaluates CanGuard products for both electrical conductivity and mechanical endurance, ensuring the gasket maintains its contact resistance and sealing properties after compression, vibration, and temperature exposure. We also perform salt fog, humidity, and corrosion testing to confirm that conductive fillers remain stable and that the gasket continues to meet required performance standards over extended service life. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide hybrid or dual-function sealing solutions?

Yes. Many modern applications require seals that provide both EMI/RFI protection and traditional environmental sealing against water, dust, or gas. Canyon Components produces hybrid gaskets and O-rings that combine conductive paths with non-conductive elastomers, achieving both electrical shielding and IP-rated environmental protection. These hybrid seals are ideal for connectors, housings, or bulkheads that must meet both EMC and ingress protection (IP) standards. We can mold conductive and insulating sections into a single component or bond them mechanically to provide seamless integration between electrical and mechanical sealing functions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are CanGuard materials compatible with aerospace and defense applications?

Yes. Many CanGuard compounds are designed to meet the performance expectations of MIL-DTL-83528, SAE AMS specifications, and NASA outgassing standards. These materials are commonly used in avionics housings, radar systems, satellite communications, and military electronics where EMI suppression is critical to mission safety and communication clarity. Canyon Components also provides documentation for material traceability, batch testing, and compliance with RoHS and REACH directives. For aerospace customers, our team can assist with design optimization to minimize weight while maximizing shielding performance and vibration resistance in extreme temperature or altitude environments. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How are EMI and RFI shielding gaskets integrated into equipment designs?

Integration depends on the geometry and operating environment of the equipment. Conductive gaskets are typically installed between conductive metal surfaces, allowing them to bridge the gap and form an electrical seal. Canyon Components offers custom die-cut, molded, and extruded profiles that match complex housing designs, from thin flange interfaces to large rectangular enclosures. For high-frequency shielding, we provide knitted wire mesh and fabric-over-foam solutions that conform to uneven surfaces without compromising contact continuity. Our engineers collaborate with design teams to ensure proper compression force, contact area, and surface finish, which are all vital to achieving consistent EMI and RFI protection. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide custom-engineered EMI and RFI shielding parts?

Absolutely. Every application has unique geometry, frequency exposure, and environmental requirements. Canyon Components specializes in custom-molded conductive O-rings, frame gaskets, connector seals, and integrated assemblies that meet precise design tolerances. We use CAD modeling and precision tooling to replicate or improve existing designs, producing components that offer both mechanical durability and electromagnetic integrity. Our rapid prototyping services allow customers to evaluate performance before committing to full-scale production, ensuring optimal fit and shielding efficiency. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What advantages does Canyon Components offer over other EMI and RFI gasket suppliers?

Canyon Components distinguishes itself through its engineering expertise, material diversity, and manufacturing flexibility. Our CanGuard product line includes materials capable of operating across extreme environments while maintaining consistent electrical and mechanical performance. We provide full testing documentation, traceable batch records, and compliance certifications with every order. Customers benefit from our ability to deliver both standard AS568 sizes and custom shapes with fast lead times and exacting tolerances. Whether the application involves sensitive aerospace avionics, ground-based radar systems, or telecommunications enclosures, Canyon Components ensures that every EMI and RFI shielding product meets the highest standards of precision, reliability, and long-term stability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!