Industries

Welcome to Canyon Components, where our expertise and cutting-edge solutions bridge the gap between innovation and industry needs. Serving a diverse array of sectors such as aerospace, automotive, healthcare, and technology, we are committed to delivering excellence and driving progress. Our tailored approach ensures that each industry we serve benefits from our deep understanding of its unique challenges and opportunities.

Below is listed many of the major industries that Canyon Components serves. Each industry has a page that dives into common certifications, popular materials, and important considerations.

Each industry has hundreds of sub industries that canyon components serves. From sanitary gaskets in food manufacturing applications, to deep sea oil drilling seals; from sealing aerospace fuel tanks to custom machined high strength gears; Canyon Components can support the needs of any application!

The engineers and consultants here at Canyon Components take pride in finding the perfect solution our customer’s needs. Contact our expert staff for assistance with any seal or application questions!

Industries

Oil Field Grade Materials

Learn more about our specialized products for the Oil & Gas Industry, highlighting our Norsok and NACE tested elastomeric materials, O-rings, and custom components designed to meet the sector's stringent specifications. It emphasizes our commitment to durability, resistance to extreme conditions, and compliance with industry standards, ensuring optimal performance in harsh operational environments.

Medical & Pharmaceutical Grade Materials

See our specialized offerings to the Medical & Pharmaceutical Industry, focusing on the supply of high-quality USP Class VI gaskets, O-rings, and custom plastic components. It emphasizes our commitment to precision, durability, and compliance with stringent industry standards, supporting critical applications in medical devices, equipment sealing, and pharmaceutical production processes.

Food & Dairy Grade Materials

Presenting our dedicated offerings to the Food and Dairy Industry, featuring FDA Compliant, NSF 51, and 3A gaskets, O-rings, and custom parts crafted to meet specific industry requirements. It underscores our focus on food-grade materials, compliance with health and safety standards, and our commitment to durability and hygiene, ensuring our products support safe and efficient production processes.

Semiconductor & Solar Grade Materials

This page details our specialized product offerings for the Semiconductor Industry, including precision-engineered gaskets, O-rings, and custom plastics that meet exacting industry specifications. It emphasizes our commitment to high purity, chemical resistance, and precision fit, ensuring our components support the critical requirements of semiconductor manufacturing and cleanroom environments.

EMI & RFI Shielding Materials

Highlighting our large array of materials and our expertise in providing EMI & RFI shielding materials, showcasing gaskets, O-rings, and custom parts designed to meet industry-specific specifications. Canyon provides solutions that ensure effective electromagnetic and radio frequency interference shielding, highlighting the importance of material conductivity, durability, and compliance with regulatory standards for optimal performance.

Drinking Water Grade Materials

This page introduces our offerings to the Drinking Water Industry, focusing on WRAS, KTW, and NSF 61 gaskets, O-rings, and custom parts that adhere to stringent industry standards for safety and purity. It underscores our commitment to providing components that ensure leak-proof, contaminant-free water delivery systems, emphasizing materials certified for potability and resistance to environmental stressors.

Military, Aerospace, & Automotive Grade Materials

This page outlines our specialized materials for the Military, Aerospace, & Automotive Industries, featuring Mil-Spec and AMS gaskets, O-rings, and custom plastics that meet rigorous specifications for durability, temperature resistance, and performance under extreme conditions. It highlights our dedication to providing high-quality, reliable components essential for the safety and efficiency of critical applications in these sectors.

Chemical Processing Materials

Learn about our offerings for the Chemical Processing Industry, emphasizing extremely resistant gaskets, O-rings, and custom parts designed to withstand aggressive chemicals and extreme temperatures. Canyon Components offers materials that meet industry-specific specifications for chemical resistance, durability, and safety, ensuring reliable sealing and containment solutions in harsh chemical environments.

Nuclear Grade Materials

Explore materials engineered for nuclear applications, designed to withstand radiation, high temperatures, and corrosive environments. Learn about their features, compliance, and performance in critical settings. Canyon Components offers materials that meet industry-specific specifications for purity, chemical resistance, durability, and safety, ensuring reliable sealing and containment solutions in harsh nuclear environments.

UL Certified Materials

This page showcases our range of UL certified materials, including gaskets, O-rings, and custom parts, designed to meet the rigorous safety and quality standards required by the industry. Canyon Components is committed to providing parts that ensure reliability, durability, and compliance with UL specifications, catering to a wide range of applications and industries.

General Purpose Materials

This page features our selection of general-purpose materials, highlighting gaskets, O-rings, and custom parts that cater to a broad spectrum of industrial applications. It underscores our commitment to versatility, quality, and performance, with materials designed to meet diverse specifications for durability, flexibility, and resistance, serving various sectors with efficiency and reliability.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

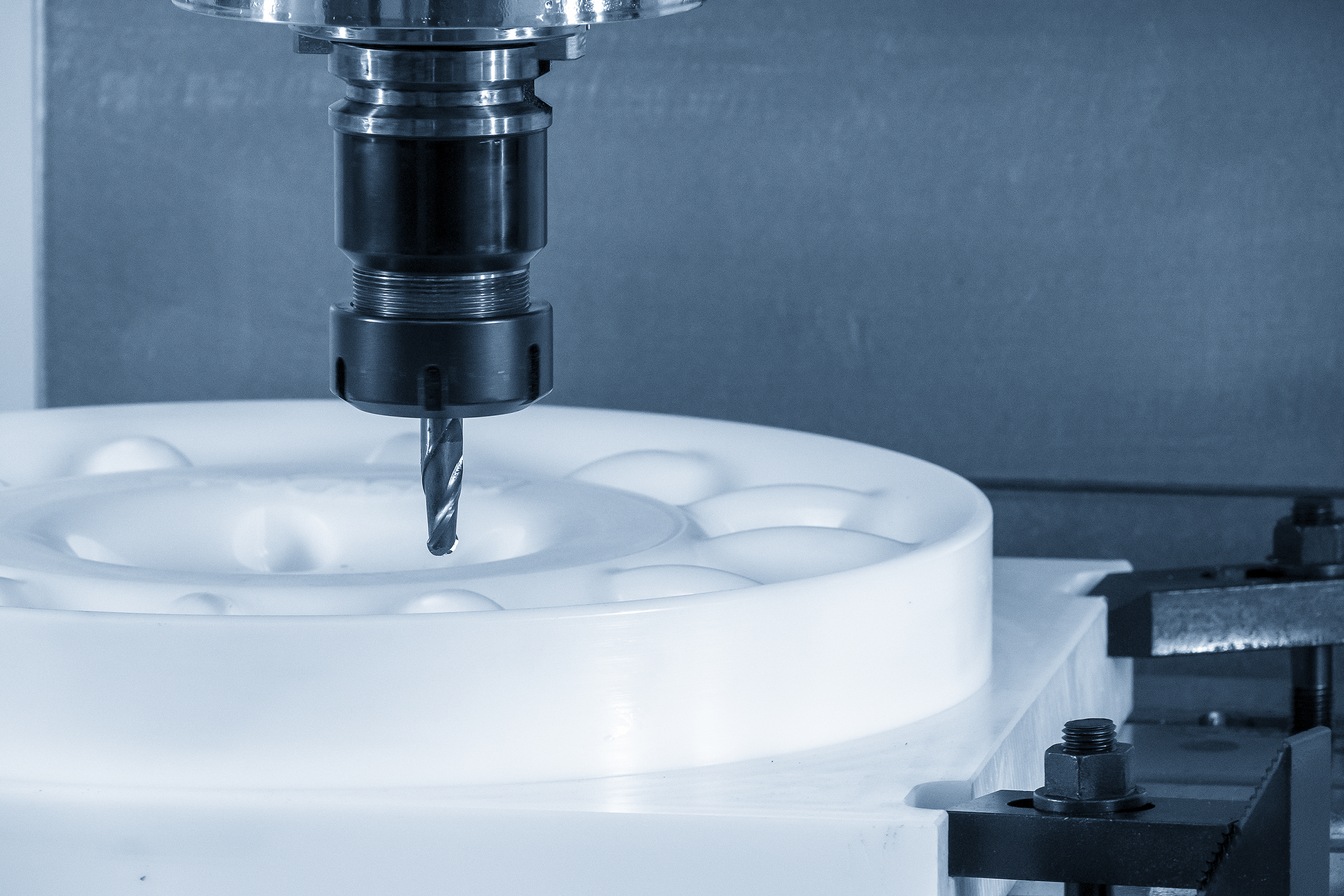

Custom Parts & Custom O-rings

Learn More

FAQ

Canyon Components supports a wide range of industries that depend on precision sealing, durability, and material performance under extreme conditions. From aerospace and automotive engineering to healthcare, semiconductor, and food production, each sector requires specialized elastomers, plastics, and metals that meet strict regulatory and environmental demands. Our engineering team provides technical assistance, material selection guidance, and compliance support to ensure every product performs reliably in its intended environment. Whether you need FFKM O-rings for chemical resistance or FDA-approved gaskets for sanitary systems, Canyon Components has the expertise to deliver complete sealing solutions.

How do sealing requirements vary between aerospace and automotive applications?

Aerospace systems experience extreme temperatures, altitude changes, and fuel exposure that require high-performance materials such as FKM, FFKM, and fluorosilicone. Automotive systems, on the other hand, prioritize resistance to hydrocarbons, pressure cycles, and vibration. Canyon Components provides both sectors with precision O-rings, gaskets, and bonded components produced from AMS, MIL-SPEC, and automotive-grade materials. Our focus on dimensional accuracy and consistency ensures safe, leak-free performance under severe conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes medical and pharmaceutical applications so demanding?

Medical and pharmaceutical equipment often operates in sterile environments where even microscopic contamination can pose a risk. Materials must be biocompatible, chemically inert, and capable of withstanding sterilization processes like autoclaving or gamma irradiation. Canyon Components supplies USP Class VI, ISO 10993, and FDA-compliant materials used in peristaltic pumps, fluid transfer systems, and surgical equipment. Cleanroom manufacturing, vacuum packaging, and full traceability ensure every component maintains its purity and reliability. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Why are specialized materials required for semiconductor manufacturing?

Semiconductor fabrication involves high-purity gases, vacuum chambers, and plasma processes that can quickly degrade conventional elastomers. Low-outgassing, high-temperature materials such as FFKM and PTFE are required to prevent contamination and particle generation. Canyon Components supplies plasma-resistant and etch-resistant compounds used in wafer etching, deposition, and cleaning systems. By maintaining tight tolerances and material cleanliness, we help semiconductor manufacturers achieve higher yield rates and longer equipment uptime. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do material requirements differ in food and beverage processing?

Food and beverage production requires materials that can handle steam cleaning, temperature cycling, and contact with both acidic and alkaline substances. Elastomers such as EPDM, silicone, and FKM are common choices for their durability and hygienic performance. Canyon Components supplies seals and gaskets certified to FDA CFR 21.177.2600, 3A Sanitary, and NSF 51/61 standards, including metal- and x-ray-detectable compounds that enhance safety. Our sanitary sealing solutions are engineered to reduce downtime and simplify maintenance during frequent washdowns. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the biggest challenges in the chemical processing industry?

Chemical processing plants expose materials to strong acids, bases, solvents, and extreme pressures. Seals must resist swelling, embrittlement, and chemical breakdown over long service cycles. Canyon Components offers FFKM, PTFE, and AFLAS compounds that withstand aggressive chemicals and elevated temperatures. Our engineers perform compatibility analysis and recommend materials based on real-world test data, ensuring safe operation in pumps, valves, and reactors where reliability is critical. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Why are elastomer and metal compatibility considerations important?

In many systems, elastomers are used alongside metals or plastics, and mismatched thermal expansion or hardness can lead to failure. Proper selection of materials ensures stability and long-term sealing integrity. Canyon Components provides guidance on metal-to-rubber bonding, hybrid assemblies, and gasket interfaces, helping customers avoid premature wear, galvanic corrosion, or mechanical stress issues. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do regulations influence material and component selection?

Compliance with industry-specific standards ensures safety, consistency, and legal acceptance of materials in production environments. Aerospace applications often require AMS, MIL-SPEC, or AS9100-certified materials, while healthcare and food applications rely on FDA, USP, and NSF compliance. Canyon Components tracks and documents all certifications, providing customers with fully traceable materials and testing data to simplify audits and meet global regulatory expectations. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can a supplier provide parts across multiple industries?

Yes, but it requires a deep understanding of each industry’s unique requirements. Canyon Components serves as a multi-industry partner, supplying O-rings, gaskets, and custom-molded parts across aerospace, automotive, semiconductor, and healthcare sectors. By offering materials that meet diverse compliance frameworks and manufacturing processes that adapt to any production volume, we ensure consistent performance and reduced lead times across industries. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do advanced materials contribute to sustainability and efficiency?

Modern materials extend product life and reduce waste through improved durability, chemical stability, and energy efficiency. For example, high-performance elastomers like FFKM reduce the frequency of maintenance shutdowns, while lightweight plastics and metals help lower energy consumption in transportation and aerospace systems. Canyon Components supports sustainable manufacturing by supplying long-lasting materials, promoting efficient design, and reducing waste through precise, application-specific engineering.