Food & Dairy Grade O-ring Materials

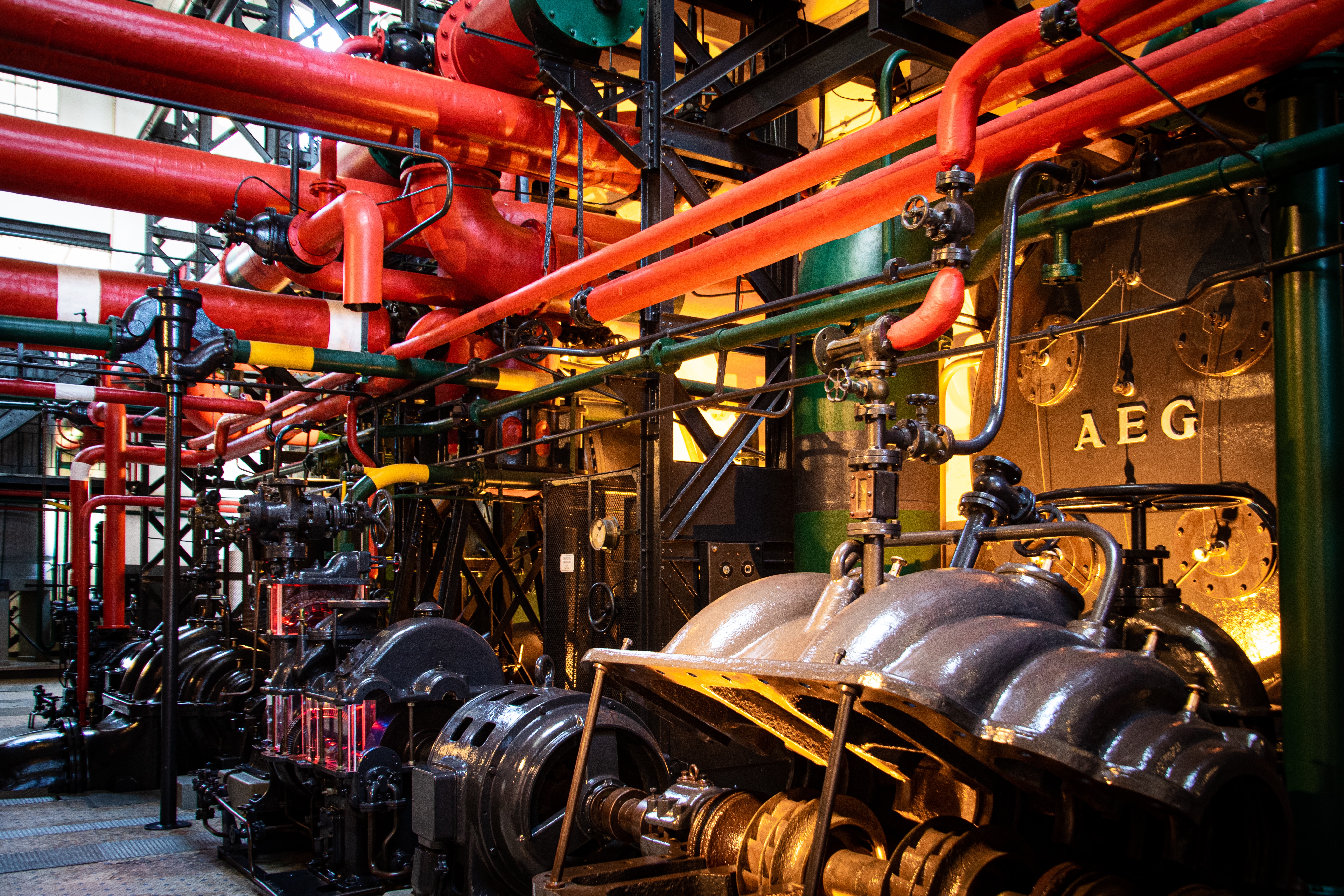

Food and dairy grade materials are essential components in the food processing and dairy industries. These materials must meet strict safety and quality standards to ensure that the products they come into contact with remain safe for consumption. In this web page, we will explore what food and dairy grade materials are, common application considerations, and the different types of certifications and materials available.

With Canyon Components, you can be sure that high quality materials that meet you needs are always readily available. Custom & standard Food & Dairy Grade Materials available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Food & Dairy Materials Available

Thousands of Food & Dairy Grade Materials are available now with Canyon Components! Some common Food & Dairy Grade Materials include the following.

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

What are Food and Dairy Grade Materials?

- Food and dairy grade materials are specifically designed and manufactured to be in direct contact with food and dairy products. These materials must meet stringent regulations and guidelines to ensure they do not contaminate the products they come into contact with and maintain the highest standards of safety and quality.

Common Considerations

- Food Safety: The primary concern in the food and dairy industry is safety. Materials used must not introduce any harmful substances into the products. Ensuring food safety is paramount to protect consumers.

- Hygiene and Cleanability: Materials must be easy to clean and sanitize to prevent the growth of harmful bacteria. Smooth, non-porous surfaces are preferred to minimize the risk of contamination.

- Resistance to Chemicals: Food processing often involves the use of various chemicals for cleaning and processing. Materials should be resistant to these chemicals to maintain their integrity.

- Temperature Resistance: In dairy and food processing, materials may be exposed to extreme temperatures. Materials should be able to withstand these temperature fluctuations without deteriorating.

- Compliance with Regulatory Standards: Adherence to industry-specific regulations and certifications is essential. Materials should meet the standards set by organizations such as the FDA (Food and Drug Administration) and NSF International.

Key Standards

- FDA CFR 21.177.2600: Canyon Components offers an array of FDA compliant materials that can be used to manufacture standard parts like O-rings and sanitary seals, as well as custom parts of any geometry. The specification typically used to define Canyon elastomers compliance to FDA standards is FDA CFR 21.177.2600 sections A, B, C, D, E, & F depending on the use case of the final component.

- Dry Foods (A-D): This section of CFR 21.177.2600 describes the regulations and the composition necessary for rubber O-rings, gaskets, & custom molded articles intended for repeated use in applications involving dry foods. It defines ingredients that are allowed in the production process of rubber parts, O-rings, gaskets, & custom molded parts.

- Aqueous Foods (A-E): Section E of CFR 21.177.2600 describes the extractable limitations under specific conditions of rubber O-rings, gaskets, & custom molded articles intended for use in applications where the articles contact aqueous foods.

- Fatty Foods (A-F): Section F of CFR 21.177.2600 describes the extractable limitations under specific conditions of rubber O-rings, gaskets, & custom molded articles intended for use in applications where the articles contact fatty foods.

- 3A Sanitary Standards: Canyon offers many materials manufactured to 3-A sanitary requirements. The USDA 3-A Sanitary Standards maintains design criteria for equipment and processing systems designed to promote acceptance of products by the USDA, FDA, and state regulatory bodies.

- NSF 51: NSF 51 compliant Canyon Components materials are also commonly used in the food manufacturing industry. This certification defines the requirements necessary in manufacturing plastics and rubbers that are used in various food equipment and food contact applications. NSF has based these requirements on certain FDA regulations.

- EU Regulation 1935/2004: The EU 1935/2004 regulation is a key piece of legislation regarding materials and articles intended to come into contact with food. Parts that are compliant with this regulation must meet specific criteria to ensure they are safe for food contact. These parts are typically made from materials that do not release harmful substances into the food, maintaining the food's quality and safety. The regulation covers a wide range of materials, including plastics, ceramics, glass, metals, and paper. EU 1935/2004 compliant parts are designed to withstand the conditions of their intended use, such as temperature changes and cleaning processes, without degrading or affecting the food product.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Food & Dairy

FDA Compliant Materials

Discover FDA compliant materials for food, medical, and pharmaceutical use, meeting strict safety standards.

NSF 51 Materials

Discover NSF 51 materials for food equipment, ensuring safety, regulatory compliance, hygiene, and durability.

USDA 3A Materials

Explore USDA 3A materials for dairy and food processing, ensuring hygiene, safety, and USDA compliance.

EU 1935/2004 Materials

Explore EU 1935/2004 materials for food contact, ensuring safety, hygiene, and compliance with regulations.

Food & Dairy Materials Available

Click here to see some of our most commonly served industries!

Each of these materials has its own advantages, limitations, and cost implications. The choice of material usually depends on factors like chemical compatibility, temperature, pressure, dynamic or static use, and specification requirements.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Industries Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Seals used in food, beverage, and dairy processing must perform reliably in demanding environments while meeting strict sanitary and regulatory standards. These components are exposed to hot water, steam, cleaning chemicals, fats, and acids that can degrade standard elastomers or cause contamination. Canyon Components provides FDA compliant, 3A Sanitary, NSF, and USP Class VI certified sealing materials that ensure product purity and process integrity. Our food-grade O-rings, gaskets, and custom-molded parts are available in Kalrez®, Canrez®, Chemraz®, and Parker® compounds, including FFKM, EPDM, silicone, and fluorosilicone. Each compound is designed to resist thermal cycling, aggressive cleaning agents, and microbial growth while maintaining compliance with global food safety standards.

What are the key regulatory standards for food and beverage seals?

Food-grade sealing materials must meet several strict international standards to ensure product safety. The most common include FDA CFR 21.177.2600 for rubber articles intended for repeated food contact, 3A Sanitary Standards for dairy and beverage processing equipment, and NSF 51 and NSF 61 for materials used in food and potable water systems. Additional certifications such as USP Class VI, EU 1935/2004, and WRAS may apply for export or specialized use. Canyon Components provides full documentation, including Certificates of Conformance, batch traceability, and compliance verification, with every shipment. All compounds are manufactured under controlled conditions to prevent cross-contamination, ensuring that every seal meets the hygienic and safety requirements of global food and beverage producers. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do sealing materials maintain hygiene and prevent contamination?

The key to hygienic sealing lies in material formulation and surface finish. Food and dairy seals must have a smooth, non-porous surface to prevent bacterial buildup or product residue. Canyon Components offers materials with low surface energy, minimal absorption, and resistance to biofilm formation. Our compounds are free from plasticizers, heavy metals, and other additives that could migrate into food or beverages. For applications requiring extra cleanliness, we supply metal-detectable and X-ray-detectable elastomers that allow in-line detection of any accidental seal fragments. Every material is carefully post-cured, washed, and inspected to eliminate residual volatiles, ensuring purity for direct food contact. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What materials are most commonly used in food and dairy sealing applications?

The most widely used food-grade materials include EPDM, silicone, FKM, and FFKM, each selected for specific chemical and temperature requirements. EPDM provides outstanding resistance to steam, water, and cleaning chemicals, making it a primary choice for pasteurizers and CIP (clean-in-place) systems. Silicone is valued for flexibility and temperature stability of over 450°F, ideal for baking, dairy, and beverage applications. FKM combines heat resistance with compatibility against oils and fats, while FFKM compounds like Canrez® and Kalrez® deliver the highest level of chemical resistance, maintaining integrity under both acidic and alkaline conditions. Canyon Components also supplies PTFE-encapsulated O-rings and composite seals for specialized applications where mechanical strength and purity are equally important. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do cleaning and sterilization cycles affect seal performance?

Cleaning and sterilization are among the most demanding conditions for food-processing seals. Systems often use high-temperature steam, alkaline detergents, chlorinated sanitizers, and peroxide-based agents that can attack conventional rubber compounds. Over time, inferior seals can become hard, cracked, or swollen, leading to leaks or product contamination. Canyon Components’ food-grade elastomers are engineered to withstand these environments without losing elasticity or changing volume. For example, our EPDM and FFKM compounds maintain mechanical integrity after hundreds of steam sterilization cycles, while our silicone materials retain flexibility in both cryogenic and high-heat environments. We also offer specialized coatings and internal lubricants that reduce friction, ease installation, and prevent surface damage during repeated cleaning operations. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide sanitary gaskets and tri-clamp seals?

Yes. We manufacture and supply tri-clamp, flange, and sanitary gaskets in FDA- and 3A-compliant materials for use in hygienic piping and processing systems. These seals are available in a variety of profiles such as standard, envelope, and screen gaskets. Canyon Components also produces custom gaskets and molded seals for pumps, valves, and heat exchangers, ensuring a precise fit and compliance with industry-specific geometries. For dairy operations, we offer seals that meet 3A 18-03 and USDA standards, providing excellent cleanability and resistance to milkstone buildup. Our sanitary sealing products are compatible with leading equipment manufacturers, offering drop-in replacements or custom-engineered alternatives for specialized systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What causes seal degradation in food and dairy applications, and how can it be prevented?

Seal degradation typically results from chemical attack, temperature cycling, or mechanical stress during repeated cleaning or operation. In dairy applications, exposure to lactic acids and cleaning agents can erode seal surfaces, while high-pressure washdowns can physically dislodge poorly fitted seals. Canyon Components helps prevent these issues through proper material selection, optimized gland design, and surface finishing. Our materials are compounded for chemical and thermal stability, and our engineering team provides groove and compression recommendations to ensure uniform sealing force. For highly aggressive cleaning environments, we may recommend FFKM or PTFE-based materials that provide long-term durability even in strong acid or base solutions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are Canyon Components’ food and dairy materials traceable and certified?

Yes. Every material and part supplied for food or dairy service comes with full traceability and certification. Canyon Components maintains documentation that includes Certificates of Conformance, FDA and 3A compliance statements, USP Class VI reports, NSF and WRAS approvals, and lot traceability records. This level of documentation supports audit readiness for HACCP, FDA, and ISO 22000-compliant facilities. Materials can also be supplied with inspection and test data confirming hardness, tensile strength, compression set, and surface finish. Our customers receive clear, organized records that simplify quality assurance and regulatory reporting. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components provide custom formulations or prototypes for new food equipment designs?

Absolutely. We work with equipment manufacturers and food-processing engineers to develop custom elastomer and plastic compounds that meet specific performance targets. This includes creating unique durometer levels, color-coded materials, and blends designed for compatibility with proprietary cleaning chemicals. Canyon Components also provides rapid prototyping and small-batch production for new system designs, allowing customers to evaluate seal performance before committing to large-scale production. All prototypes can be supplied with the same level of certification and documentation as standard parts, ensuring seamless transition from design to manufacturing. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a reliable partner for the food and dairy industry?

Canyon Components stands apart by combining regulatory expertise, technical precision, and responsiveness. We understand that food and dairy manufacturers must maintain continuous operation and regulatory compliance while minimizing downtime. Our engineering team provides fast support for material selection, cross-referencing, and custom gasket design. We maintain an extensive inventory of FDA and 3A compliant materials, ensuring short lead times and consistent quality. Beyond supplying parts, Canyon Components serves as a technical resource, helping customers meet hygienic design standards, extend seal service life, and maintain absolute confidence in their food and dairy production systems. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!