Oil Field Grade Materials

The oil and gas industry relies on robust and reliable materials to withstand harsh environments and maintain operational integrity. Oil field grade materials are specifically designed and tested to meet these demands. In this web page, we will explore the significance of oil field grade materials, common application considerations, and discuss standards like AED, NACE TM0297, and NORSOK M-710 that govern these materials.

With Canyon Components, you can be sure that high quality materials that meet you needs are always readily available. Custom & standard Oil Field Grade Materials available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Oil Field Materials Available

Thousands of Oil Field Grade Materials are available now with Canyon Components! Some common Oil Field Grade Materials include the following.

Oil Field Grade Materials Available

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

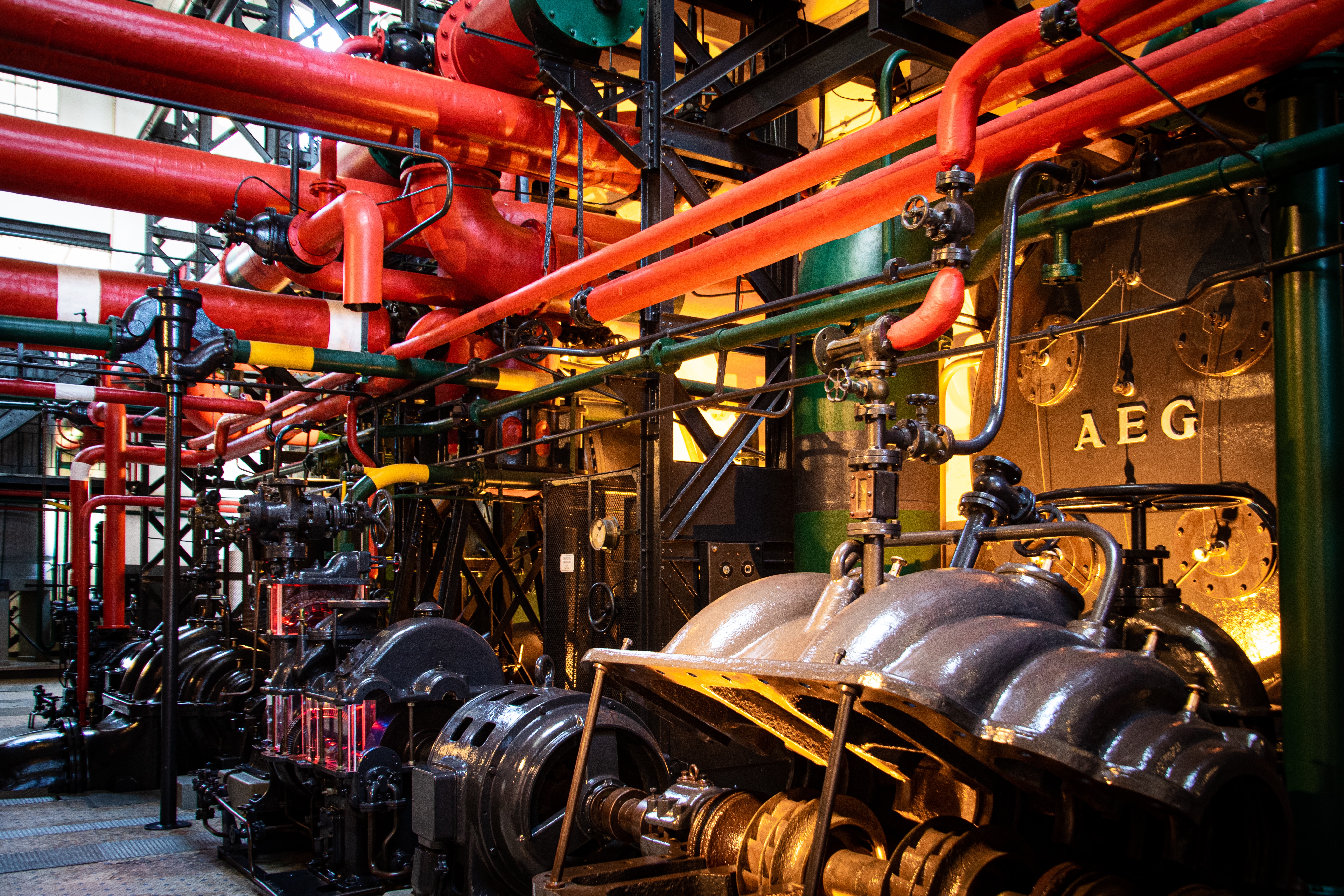

What are Oil Field Grade Materials?

- Oil field grade materials are substances, components, or equipment engineered to withstand the extreme conditions encountered in the oil and gas extraction and processing industry. These materials must be highly durable, corrosion-resistant, and capable of withstanding high pressures and temperatures.

Common Considerations

- Corrosion Resistance: Materials must resist corrosion caused by exposure to harsh chemicals and environments, preventing equipment failure and costly downtime.

- Strength and Toughness: Materials must exhibit high tensile strength and toughness to withstand the mechanical stresses and loads encountered in drilling, production, and processing operations.

- Temperature and Pressure Resistance: Oil field materials must endure a wide range of temperatures and pressures, from arctic conditions to high-temperature reservoirs.

- Chemical Compatibility: Materials should be compatible with the various chemicals and fluids used in drilling, production, and processing, preventing chemical reactions that could compromise safety and performance.

- Regulatory Compliance: Compliance with industry standards and regulations is essential to ensure safety, environmental responsibility, and operational efficiency.

- Longevity: Materials should have a long service life to reduce maintenance costs and equipment replacement frequency.

Material Options

- Advanced Engineering Design (AED) Materials: AED materials are designed to withstand extreme temperatures and pressures, making them suitable for deep-sea drilling and high-pressure applications.

- NACE TM0297 Compliant Materials: NACE TM0297 materials have undergone specific testing to show the materials performance under high pressure carbon dioxide applications where explosive decompression is a risk. It is common for materials, O-rings, gaskets, & custom molded parts that have undergone NACE TM0297 testing to be considered "anti-explosive decompression" (AED).

- NORSOK M-710 Certified Materials: Similar to NACE, NORSOK M-710 materials have undergone specific testing to show the materials performance under high pressure carbon dioxide applications where explosive decompression is a risk. It is common for materials, O-rings, gaskets, & custom molded parts that have undergone NORSOK M-710 testing to be considered "anti-explosive decompression" (AED). NORSOK M-710 also tests chemical compatibility in sour gas.

- Spring Energized Seals & Oil Seals: Filled PTFE and PEEK polymers are resistant to explosive decompression and are highly effective at a wide range of temperatures when paired with a metallic spring energizer in the form of a Spring Energized Seal or custom oil seal.

- Stainless Steel Alloys: Stainless steel alloys, such as 316 and 316L, are resistant to corrosion and are used in oil field equipment like pipelines, valves, and wellhead components.

- High-Strength Carbon Steel: High-strength carbon steels are utilized in drilling equipment and pipelines due to their excellent mechanical properties and durability.

- Exotic Alloys: Exotic alloys like Inconel and Monel are chosen for their exceptional resistance to high temperatures, corrosive environments, and extreme pressure conditions.

- Corrosion-Resistant Coatings: Coatings such as epoxy and polyurethane are applied to surfaces to provide an additional layer of protection against corrosion.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Oil Field & High Pressure

API 6A Materials

Discover API 6A materials for oil and gas, ensuring compliance and reliable performance in extreme conditions.

NORSOK M-710 Materials

Explore NORSOK M-710 anti-explosive decompression materials for oil and gas, ensuring reliability and compliance in harsh environments.

NACE TM0297 Materials

Discover NACE TM0297 anti-explosive decompression materials for sour gas applications, ensuring corrosion resistance, durability, and compliance.

Oil Field Materials Available

Click here to see some of our most commonly served industries!

Each of these materials has its own advantages, limitations, and cost implications. The choice of material usually depends on factors like chemical compatibility, temperature, pressure, dynamic or static use, and specification requirements.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Industries Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Oil field operations place extraordinary stress on sealing materials, combining extreme pressure, corrosive fluids, rapid temperature changes, and abrasive contaminants in a single environment. Every system, from wellhead control and drilling tools to refining and transportation equipment, depends on seals that can endure these conditions without deforming, cracking, or leaking. Canyon Components designs and supplies sealing products engineered specifically for the oil and gas industry. Our custom O-rings, gaskets, and molded components are made from advanced materials such as Kalrez®, Canrez®, Chemraz®, and Parker® compounds, as well as FFKM, FKM, HNBR, EPDM, and Aflas®. Each compound is carefully formulated and tested for chemical compatibility, explosive decompression resistance, and long-term sealing reliability in both onshore and offshore environments.

What are the most common failure modes for oil field seals?

Failure in oil field seals often results from a combination of thermal cycling, pressure spikes, chemical attack, and mechanical wear. Typical failure modes include extrusion damage, rapid gas decompression (RGD), cracking, thermal hardening, and volume swell. Exposure to drilling fluids and sour gas mixtures can accelerate these effects, leading to premature leakage or component failure. Canyon Components mitigates these risks by supplying materials with controlled cross-linking structures and internal lubricants that limit gas absorption and improve flexibility. Our compounds are extensively tested under compression set and decompression cycles to replicate extreme operating conditions, ensuring they maintain elasticity, sealing force, and dimensional stability throughout long-term use. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Which materials are most suitable for oil and gas applications?

Material selection depends on the system’s pressure, temperature, and chemical composition. FFKM compounds, such as Canrez® and Kalrez®, are ideal for environments requiring resistance to strong acids, sour gas, and amines at temperatures over 600°F. FKM (Viton®) is suitable for hydrocarbons and fuels, balancing cost efficiency with thermal and chemical durability. HNBR combines exceptional mechanical strength with oil and abrasion resistance, making it ideal for packers, blowout preventers, and dynamic applications. Aflas® provides superior resistance to steam, bases, and amine corrosion, while EPDM is often chosen for water, glycol, or steam injection systems. Canyon Components maintains a complete library of tested compounds to match customer requirements for chemical compatibility, compression resistance, and flexibility under pressure. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does explosive decompression (AED or RGD) affect seals, and how is it prevented?

Explosive decompression occurs when gases absorbed into an elastomer under high pressure escape too rapidly during pressure release. This sudden expansion creates internal voids, blistering, or cracking, which can destroy a seal in seconds. In oil and gas environments, where pressures can exceed 20,000 psi, this phenomenon is one of the leading causes of seal failure. Canyon Components supplies AED-rated materials such as high-density FKM, HNBR, and FFKM compounds tested under NORSOK M-710 and NACE TM0297 standards. These materials feature controlled permeability and optimized polymer structure that allow gases to vent gradually, preventing internal rupture. We also advise proper groove design and compression ratios to further minimize decompression-related stress and extend seal service life. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What testing and validation processes are performed on oil field materials?

Canyon Components conducts a comprehensive range of tests to confirm material performance under simulated oil field conditions. Testing includes ASTM D471 fluid compatibility, compression set retention, tensile and elongation analysis, and NORSOK M-710 explosive decompression testing. We also evaluate resistance to amines, methanol, drilling muds, and crude oil derivatives to confirm that the material will maintain structural integrity over time. For high-temperature validation, materials undergo prolonged exposure testing up to 600°F to monitor hardness and elasticity changes. When required, we coordinate third-party testing for NACE, API 6A, and MIL-SPEC compliance. All test results are documented and traceable, ensuring that each compound meets or exceeds the industry’s performance and regulatory requirements. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are Canyon Components’ seals compatible with common drilling and completion fluids?

Yes. Our sealing materials are designed for compatibility with a wide range of drilling and completion fluids, including hydrocarbon-based muds, synthetic drilling fluids, water-glycol systems, corrosion inhibitors, and hydraulic oils. Standard elastomers often swell or degrade in these environments, but Canyon Components’ formulations are engineered to maintain volume stability and tensile strength after extended chemical exposure. For systems that use aggressive additives or cleaning solutions, we recommend FFKM or Aflas® compounds, which provide near-universal chemical resistance. Our materials are also tested against various lubricants, methanol, and sour gas to ensure reliable sealing even in highly reactive or abrasive fluid environments. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What components are most critical for sealing performance in oil and gas systems?

Oil and gas systems depend on a wide array of seals, each designed for specific pressure, motion, and chemical conditions. O-rings remain the most common sealing element, used in static or slow dynamic applications. Backup rings and T-seals prevent extrusion in high-pressure environments. Packer elements, bonded metal-to-rubber seals, and spring-energized PTFE seals are used for dynamic motion and extreme pressure cycling. Canyon Components designs and manufactures all of these parts to exact tolerances, ensuring proper gland fit and uniform compression across the sealing surface. Each part can be supplied with coatings or lubricants to reduce installation friction, improve wear resistance, and enhance overall seal longevity. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components produce seals for high-pressure and high-temperature wells?

Yes. Our materials are engineered for both HPHT (High Pressure, High Temperature) and ULHP (Ultra-High Pressure) environments, where conventional elastomers fail. Canyon Components produces FFKM and HNBR compounds capable of continuous use above 500°F while maintaining low compression set and flexibility. In extreme cases, we recommend metal-energized or composite sealing systems that combine the resilience of elastomers with the structural support of metallic springs or retainers. Our seals are used in downhole drilling tools, subsea valves, and refinery equipment where both thermal and chemical endurance are essential. Every batch is tested for physical stability, ensuring reliable performance under conditions that push materials to their theoretical limits. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components support maintenance and replacement programs for oil field customers?

We recognize that downtime in the oil field has major financial consequences, so we provide fast, reliable replenishment services for both standard and custom seals. Canyon Components offers inventory management programs, blanket purchase orders, and on-site consignment options to keep critical components available at all times. We also assist with reverse engineering of legacy parts, allowing operators to replace discontinued seals with modern equivalents that improve durability and ease of installation. Each replacement component is verified for dimensional accuracy, material equivalence, and compliance with performance standards such as API 6A and ASTM D2000. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What sets Canyon Components apart from other seal suppliers in the oil and gas industry?

Canyon Components combines deep material expertise with application-specific engineering. Unlike suppliers that only distribute standard O-rings, we manufacture and customize components for each environment. Our approach integrates material testing, design optimization, prototyping, and documentation into every project. Customers gain access to advanced materials like Canrez® FFKM, which rivals Kalrez® and Chemraz® in chemical and thermal performance but with improved cost efficiency and faster availability. We also maintain robust traceability for every part, providing Certificates of Conformance, test data, and batch documentation to simplify compliance audits. The result is a partnership focused on reducing downtime, improving performance, and ensuring reliability in even the harshest oil field conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!