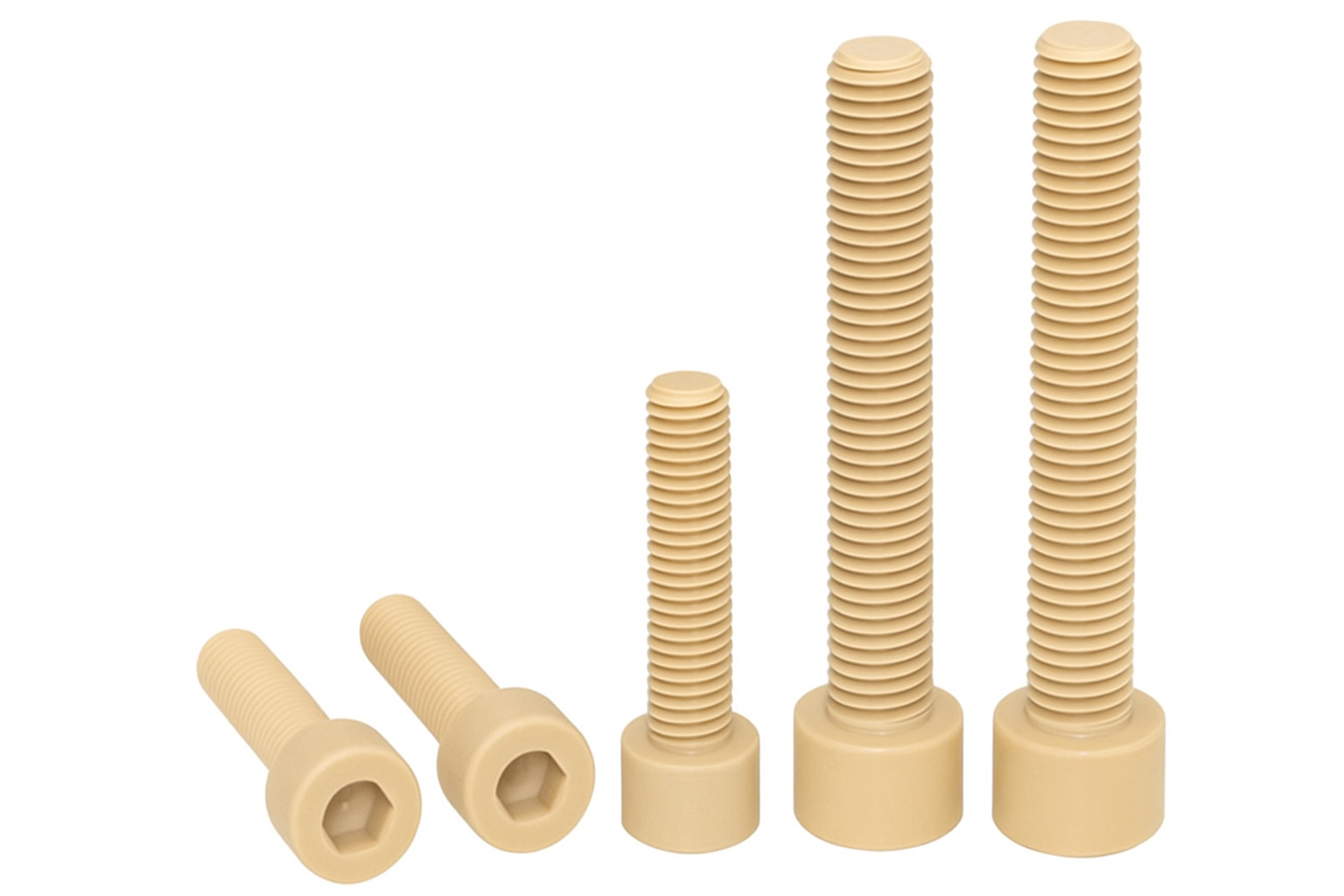

PEEK Fasteners

PEEK (Polyetheretherketone) fasteners are engineered for extreme environments where conventional metallic fasteners fall short. Known for their superior mechanical strength, thermal stability, chemical resistance, and electrical insulation, PEEK fasteners serve as ideal solutions for high-performance applications in aerospace, semiconductor, medical, chemical processing, and energy sectors. As a high-performance thermoplastic, PEEK offers the added benefits of weight reduction, non-magnetic properties, and corrosion resistance, making it a preferred alternative to metals in critical applications.

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Keywords: PEEK raw material, high-performance thermoplastic, PEEK plastic resin, PEEK granules, medical-grade PEEK, industrial PEEK polymer, unfilled PEEK, carbon-filled PEEK, bearing-grade PEEK, PEEK fasteners, high-performance plastic screws, chemical-resistant polymer bolts, custom machined PEEK hardware, PEEK bolts and nuts for cleanroom use, high-temperature plastic fasteners

Types of PEEK Fasteners

Canyon Components supplies and manufactures a wide range of PEEK fasteners, available in both standard and custom configurations:

- Screws: Socket head, pan head, flat head, and other configurations

- Bolts: Hex head, flange, shoulder, and custom bolt designs

- Nuts: Hex, wing, lock, and specialty types

- Washers: Flat, sealing, insulating, and dielectric washers

- Custom-Molded or Machined Components: Designed to customer specifications for unique fastening needs

We offer sizes ranging from micro-fasteners to large structural components, with threads available in UNC, UNF, metric, and specialty formats. Our components can meet or exceed DIN, ISO, and ASTM fastener standards.

Material Grades and Fillers

Our PEEK fasteners are available in a variety of grades and formulations, tailored to the specific mechanical and environmental demands of each application:

- Virgin PEEK: Highest purity and excellent biocompatibility; ideal for medical and cleanroom applications

- Carbon-Filled PEEK: Enhanced tensile strength and stiffness; great for structural loads

- Glass-Filled PEEK: Improved dimensional stability and reduced thermal expansion

- Bearing-Grade PEEK: Filled with PTFE, graphite, or carbon for low-friction and wear-resistant fasteners

- Antistatic/Conductive PEEK: Designed for ESD-sensitive environments such as electronics and semiconductor fabs

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Machining and Customization

Canyon Components offers comprehensive capabilities for manufacturing PEEK fasteners via CNC machining, injection molding, and hybrid methods:

- Tight-tolerance CNC threading and dimensional control

- Multi-axis machining for complex geometries

- Insert molding and overmolding for captive or embedded fasteners

- Custom coatings, secondary finishes, and post-machining treatments

- Scalable production from prototyping through full-scale manufacturing

Benefits of PEEK Fasteners

PEEK fasteners deliver performance advantages that make them a go-to solution for extreme environments:

- High strength-to-weight ratio and mechanical resilience

- Outstanding chemical resistance to acids, solvents, and hydrocarbons

- Operational performance in continuous temperatures up to 260°C (500°F)

- Flame retardant (UL 94 V-0 ratings available)

- Radiolucent and sterilizable by gamma, autoclave, or EtO methods

- Electrically insulating and non-magnetic

- Corrosion-free operation in saltwater, steam, or aggressive media

Why Choose Canyon Components

Canyon Components supports critical quality and regulatory requirements with full traceability, including ISO 9001-compliant quality systems, RoHS and REACH compliance for environmental safety, USP Class VI and ISO 10993 for medical-grade parts, and NORSOK and NACE standards for oil and gas compatibility (upon request).

We bring unmatched experience and technical support to every PEEK fastener project, offering deep expertise in high-performance thermoplastics and material selection, precision manufacturing for both custom and standard components, rapid prototyping, responsive customer service, and a reliable supply chain with fast lead times for critical projects.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Back To Fasteners Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More