PEEK Machining Profiles

PEEK (Polyetheretherketone) is a high-performance thermoplastic prized for its exceptional strength, chemical resistance, and dimensional stability under heat and mechanical stress. Its unique machinability makes it an ideal material for mission-critical applications in industries such as semiconductor manufacturing, aerospace, medical devices, and high-performance industrial equipment. At Canyon Components, we support both ends of the manufacturing spectrum: we supply PEEK profiles—including tubes, rods, sheets, and blocks—for customers who do their own in-house machining, and we offer full-service CNC machining of custom PEEK parts built to exacting specifications.

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Keywords: PEEK raw material, high-performance thermoplastic, PEEK plastic resin, PEEK granules, medical-grade PEEK, industrial PEEK polymer, unfilled PEEK, carbon-filled PEEK, bearing-grade PEEK, PEEK CNC machining, precision PEEK profiles, custom machined PEEK, PEEK fabrication services, PEEK rods, PEEK tubes, PEEK sheets, PEEK blocks.

PEEK Profiles for Machining

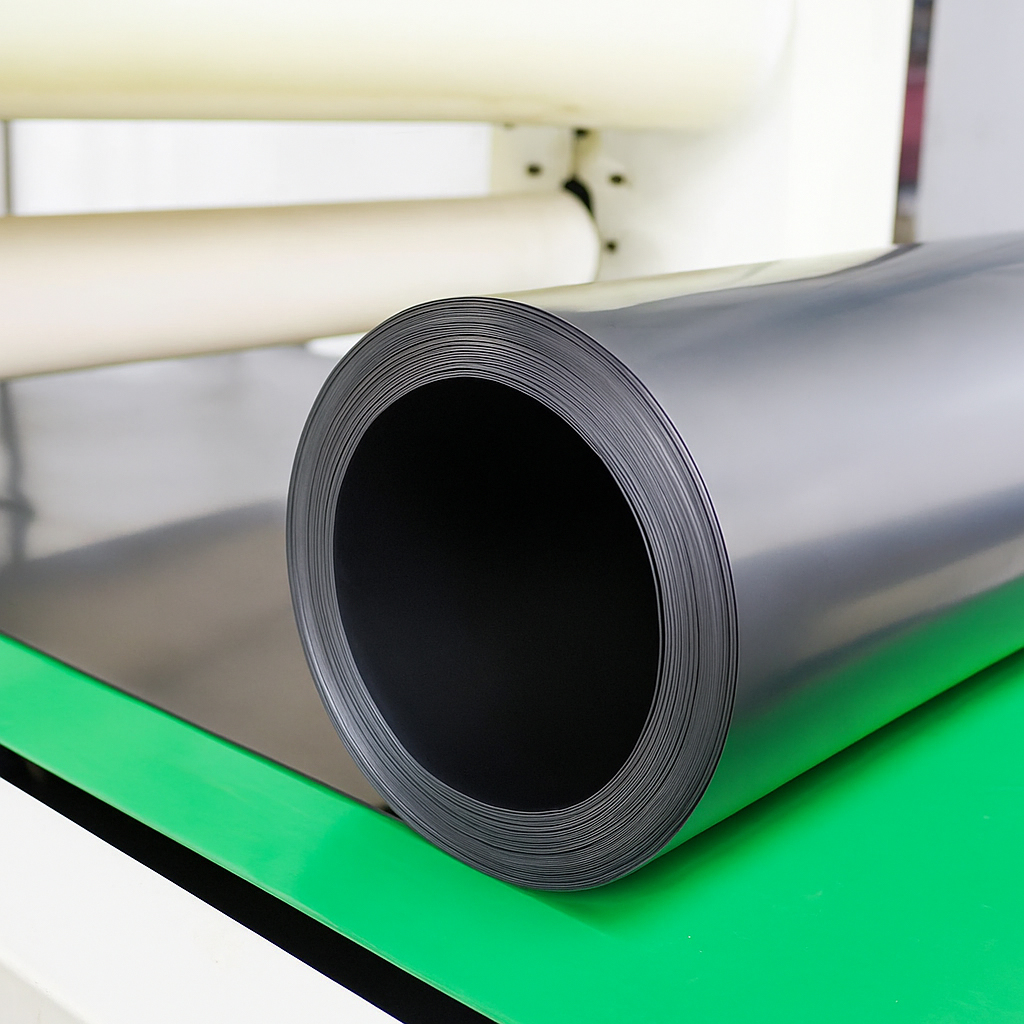

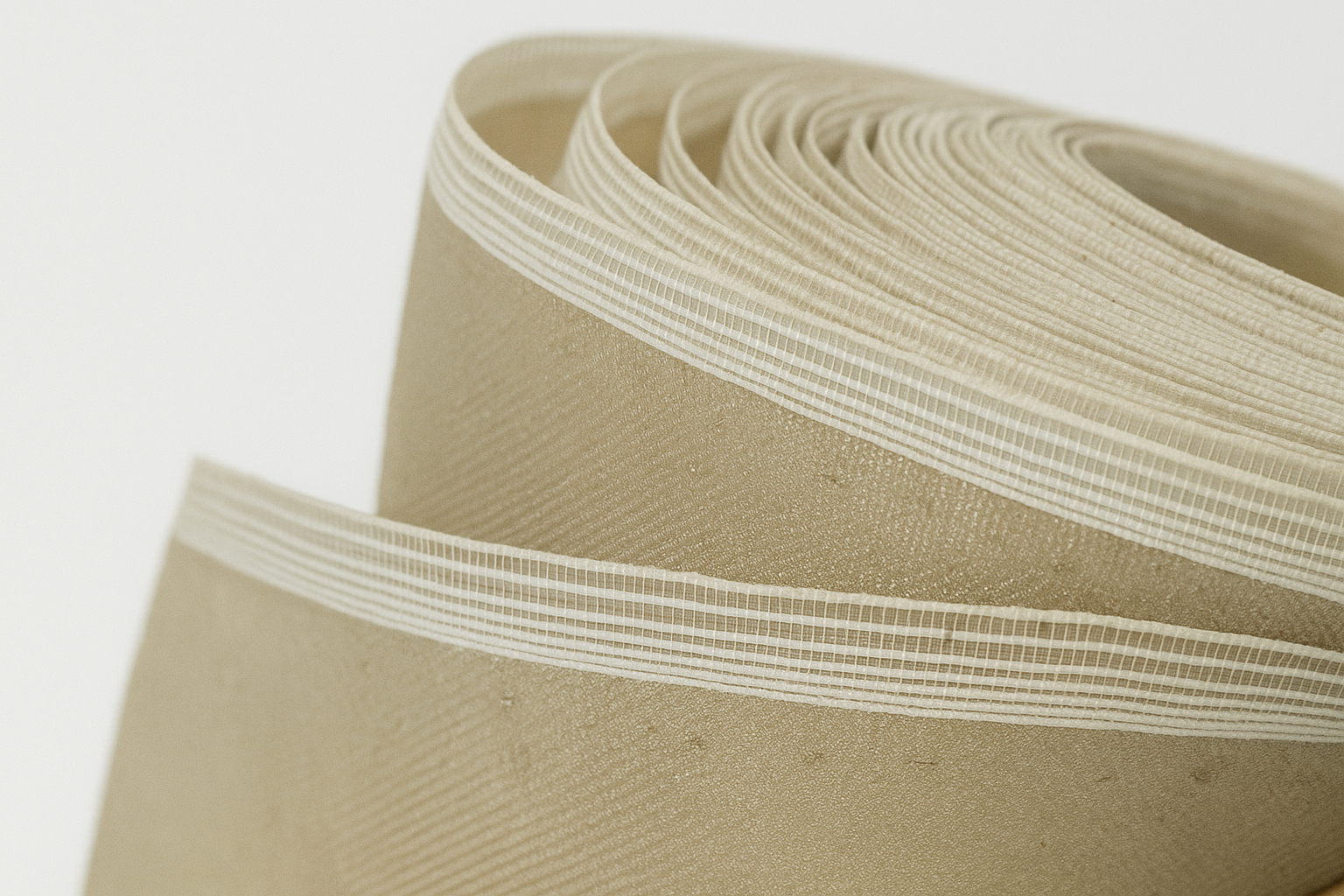

We supply high-quality PEEK profiles including rods, tubes, sheets, and blocks in a variety of grades such as unfilled, glass-filled, carbon-filled, bearing-grade, and medical-grade PEEK. These profiles are ideal for customers seeking to machine their own precision parts. Contact us for pricing and availability across different dimensions, tolerances, and specialty formulations. Our profiles are stress-relieved for dimensional stability and offered in options suitable for both high-temperature and cleanroom applications.

PEEK Profiles for Machining

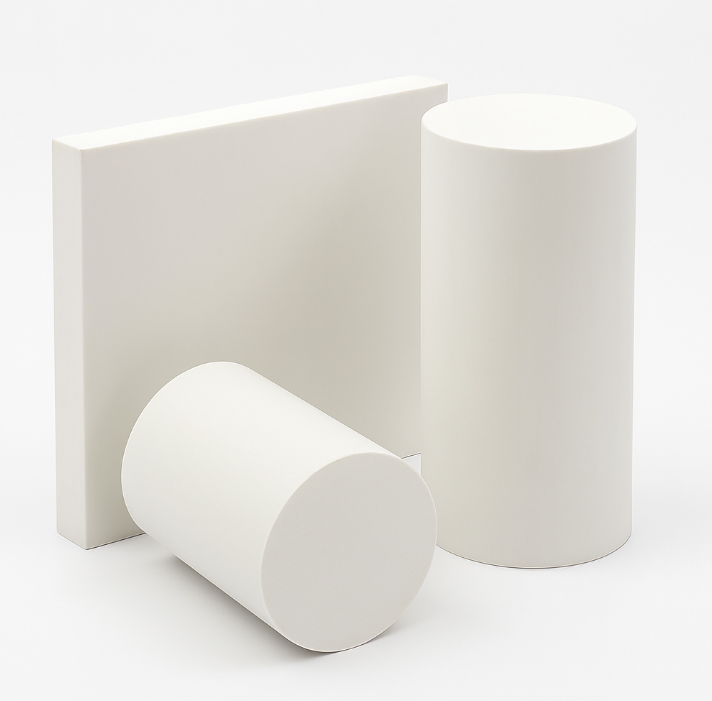

Canyon Components offers a wide range of PEEK stock shapes ready for precision machining:

- PEEK Rods: Available in multiple diameters and grades, ideal for turned or milled components.

- PEEK Tubes: Suited for hollow parts, insulators, and lightweight structural components.

- PEEK Sheets: Useful for creating flat stock parts, gaskets, and custom panels.

- PEEK Blocks: Excellent for parts requiring deep milling or multi-axis machining.

All profiles are available in virgin and filled grades such as glass-filled, carbon-filled, and bearing-grade materials. We offer stress-relieved stock to minimize distortion during machining, and select profiles are cleanroom-compatible, making them suitable for semiconductor and medical applications.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

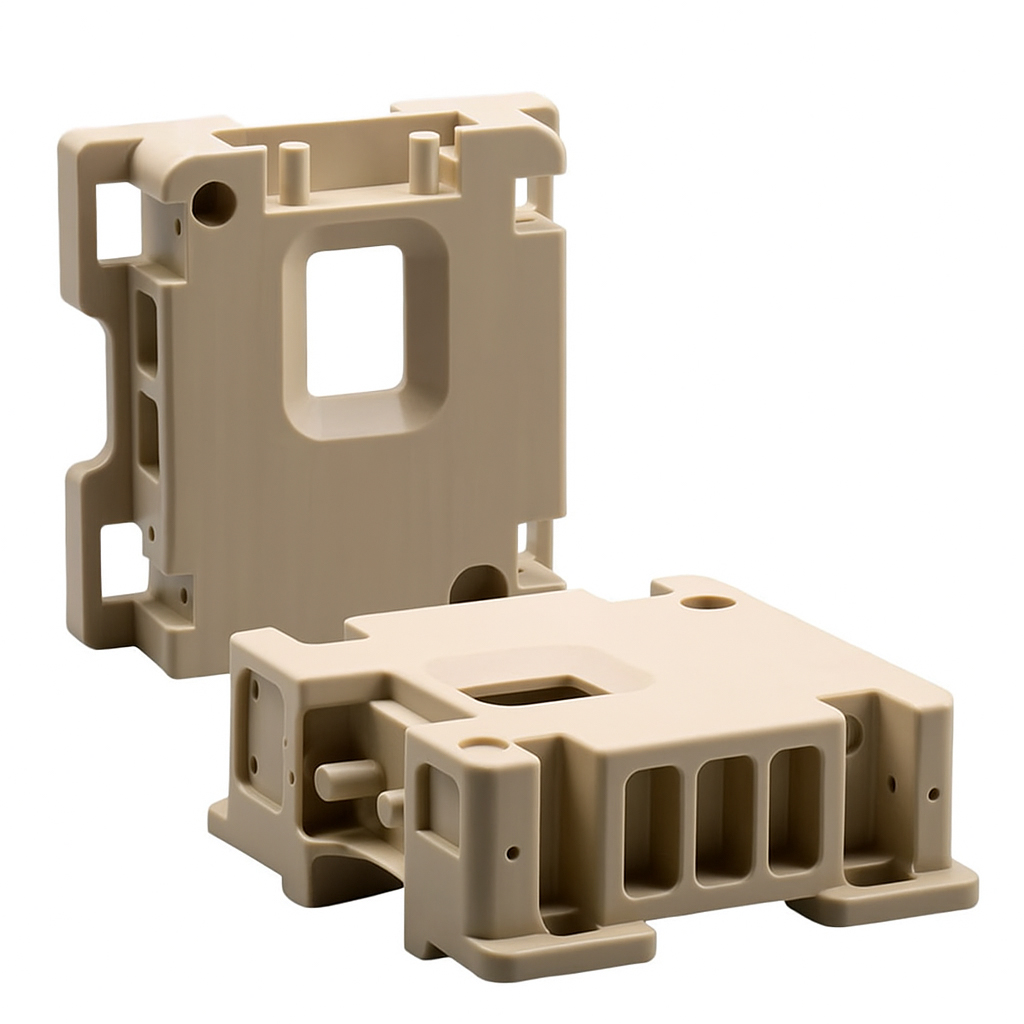

Custom Machined PEEK Parts

Custom Machined PEEK Parts

In addition to raw profiles, Canyon Components provides precision CNC machining of custom PEEK parts. Our capabilities include:

- CNC Turning and Milling: Tight-tolerance cylindrical and prismatic parts

- Drilling and Threading: Complex internal geometries, fasteners, and connectors

- Surface Finishing: Optimized for critical interfaces, wear zones, or fluid exposure

We routinely manufacture:

- Insulators and electrical standoffs

- Sealing components and custom gaskets

- Medical device enclosures and components

Our machining process supports high-spec tolerance control, thin-wall structures, and intricate geometries with excellent repeatability.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Design Considerations

Machining PEEK requires attention to several key factors:

- Stress Relief: Always use stress-relieved stock to avoid warping

- Anisotropy: Consider grain orientation in extruded or molded profiles

- Thermal Expansion: Account for thermal growth in high-temperature environments

- Post-Machining Tolerance: Leave allowances for final conditioning, especially in tight-tolerance fits

- Our engineers are available to assist with design-for-manufacturing and material optimization.

Common Applications for Machined PEEK

PEEK's combination of thermal, mechanical, and chemical resistance makes it ideal for a variety of demanding applications:

- Semiconductor: Wafer guides, insulators, chemical-resistant components

- Aerospace: Thermal brackets, lightweight bushings, and sensor enclosures

- Medical Devices: Reusable surgical tools, housings, and sterilizable assemblies

- Industrial: Seals, wear plates, high-load structural components

Get a Quote Now!

Manufacturing Options for PEEK

PEEK parts can be manufactured using several methods, each suitable for different applications and part complexities.

Each of these methods has its own advantages, limitations, and cost implications. The choice of manufacturing technique usually depends on factors like the complexity of the design, required precision, material properties, and production volume.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

PEEK Pros

- Excellent wear and chemical resistance

- Maintains dimensional stability under thermal load

- High strength-to-weight ratio

- Biocompatibility and low outgassing

PEEK Cons

- Higher raw material cost than commodity plastics

- Requires sharp tooling and proper chip evacuation

- Slower feed rates compared to metals or soft plastics

PEEK Profile Material Options

Standard PEEK

Virgin, unfilled PEEK offers excellent strength, thermal stability, and chemical resistance. It is ideal for high-purity applications and general machining. Available in tubes, rods, blocks, and slabs.

Voltage Resistant PEEK

Formulated for high dielectric strength and insulation performance, this grade is ideal for electrical components, insulators, and connectors. Available in tubes, rods, blocks, and slabs.

Low Thermal Conductivity PEEK

Designed to reduce heat transfer, this grade supports applications in cryogenics and thermal isolation systems. Available in tubes, rods, blocks, and slabs.

PTFE-Filled PEEK

Combines PEEK’s strength with the lubricity of PTFE for superior wear resistance and low friction, ideal for moving parts and bearings. Available in tubes, rods, blocks, and slabs.

Antistatic PEEK

Modified for controlled surface resistivity, this grade prevents static discharge in electronics and cleanroom equipment. Available in tubes, rods, blocks, and slabs.

Ceramic-Filled PEEK

Provides enhanced stiffness and thermal performance while maintaining excellent dimensional stability. Suitable for high-heat or abrasive environments. Available in tubes, rods, blocks, and slabs.

Glass Fiber-Filled PEEK

Offers improved stiffness and load resistance while maintaining processability. Suitable for brackets and housings. Available in tubes, rods, blocks, and slabs.

High Strength Carbon Fiber-Filled PEEK

Reinforced with high carbon content for superior mechanical strength and conductivity. Used in aerospace and structural parts. Available in tubes, rods, blocks, and slabs.

Carbon-Filled PEEK

Balanced reinforcement for increased wear resistance, thermal conductivity, and stiffness. Widely used in bushings and seals. Available in tubes, rods, blocks, and slabs.

Back to Plastics Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More