Military, Aerospace, & Automotive Grade Materials

In the military, aerospace, and automotive industries, materials play a pivotal role in ensuring safety, performance, and reliability. Military, aerospace, & automotive grade materials are specifically designed and rigorously tested to meet the demanding requirements of these sectors. In this web page, we will explore the significance of these materials, common application considerations, and discuss the different types used across these industries.

With Canyon Components, you can be sure that high quality materials that meet you needs are always readily available. Custom & standard Military, Aerospace, & Automotive Grade Materials available now!

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Military, Aerospace, & Automotive Materials Available

Thousands of Military, Aerospace, & Automotive Grade Materials are available now with Canyon Components! Some common Military, Aerospace, & Automotive Grade Materials include the following.

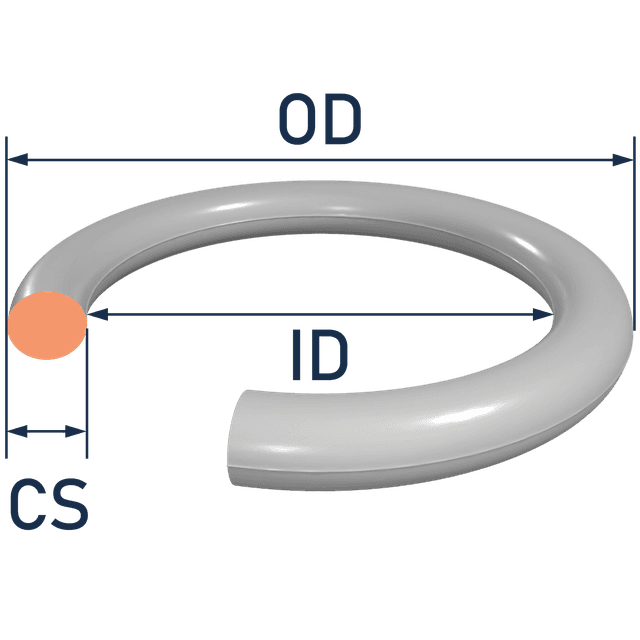

This table shows many of our standard materials and links out to our O-ring store. Get in touch with us if you need a custom gasket, custom molded part, or non-standard geometry!

Filter by

Temperature Search (°C)

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

What are Military, Aerospace, & Automotive Grade Materials?

- Military, aerospace, & automotive grade materials are substances, components, or equipment engineered to excel in the challenging and high-performance environments of these sectors. These materials must meet strict criteria for strength, durability, thermal stability, and safety.

Common Considerations

- Weight and Strength: Materials must strike a balance between low weight and high strength to meet the stringent weight restrictions in aerospace and automotive applications.

- Thermal Performance: Thermal stability and resistance to extreme temperatures are crucial, particularly in aerospace and automotive engine components.

- Durability and Reliability: Materials must withstand rigorous testing, vibrations, and mechanical stresses, ensuring long-term durability and reliability.

- Safety and Security: Materials should comply with safety standards and regulations, ensuring the protection of personnel and assets.

- Cost-Efficiency: While performance is vital, cost considerations are essential to optimize material selection and production processes.

Material Options

Fluorosilicone:

- Military: Fluorosilicone is used in military applications for its resistance to fuel, oil, and solvents, particularly in fuel systems and various seals.

- Aerospace: In aerospace, it's valued for its wide temperature range and resistance to fuels and degradation in harsh environments, making it suitable for seals and gaskets in aircraft.

- Automotive: For the automotive industry, fluorosilicone finds use in fuel systems and transmission components due to its resistance to petroleum oils and fuel.

EPDM (Ethylene Propylene Diene Monomer):

- Military: EPDM's durability and weather resistance make it suitable for outdoor military equipment and vehicles, protecting against water, UV, and temperature variations.

- Aerospace: In aerospace, EPDM is used for its excellent resistance to ozone, weathering, and aging, ideal for window seals, hoses, and insulation materials in certain aircraft applications.

- Automotive: In automotive applications, EPDM is commonly used for weatherstripping, door seals, and hoses due to its resistance to ozone, coolants, and heat.

NBR (Nitrile Butadiene Rubber):

- Military: NBR is used in military applications for gaskets and seals in fuel handling systems because of its resistance to oils and fuels.

- Aerospace: It's utilized in aerospace for components like fuel hoses and seals, offering good resistance to oils and various hydrocarbons.

- Automotive: In the automotive industry, NBR is prevalent in fuel and oil handling systems, like fuel hoses, gaskets, and O-rings, due to its oil resistance.

Silicone:

- Military: Silicone's flexibility and high-temperature resistance make it ideal for military electronic components and seals in extreme environments.

- Aerospace: Widely used in aerospace for its thermal stability and low outgassing properties, silicone is ideal for seals, gaskets, and insulation in aircraft.

- Automotive: In automotive, silicone is used for hoses, gaskets, and seals, particularly in high-temperature areas like engine compartments.

FKM (Fluorocarbon Rubber):

- Military: FKM is used for seals and gaskets in military vehicles and equipment due to its excellent resistance to high temperatures, fuels, and chemicals.

- Aerospace: In aerospace, it's used for O-rings, seals, and gaskets, especially in fuel systems and engines, due to its resistance to jet fuel, hydraulic fluids, and high temperatures.

- Automotive: FKM finds application in automotive fuel systems, transmission seals, and O-rings, thanks to its resistance to high temperatures and various fluids.

EMI & RFI Shielding Materials:

- Military: These materials are critical in military applications for protecting sensitive electronic equipment from electromagnetic interference and radio frequency interference.

- Aerospace: In aerospace, they are used in aircraft electronics and communication systems to prevent interference and ensure the reliability of onboard systems.

- Automotive: In the automotive sector, EMI and RFI shielding materials are used in electronic systems to prevent interference with critical vehicle functions and communication systems.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Military, Aerospace, & Automotive

Glossary of Specifications

Explore our Glossary of Specifications, offering clear definitions and explanations of key industry standards and certifications. Learn how these specifications impact material selection and compliance in various industries.

AMS (Aerospace Material Specification)

Learn about AMS (Aerospace Material Specification) materials, designed to meet rigorous standards for aviation and aerospace industries. Discover their features, compliance, and how they ensure performance and safety in critical applications.

Mil-Spec Elastomeric Materials

Discover Mil-Spec elastomeric materials, engineered to meet stringent military specifications for strength, durability, and precision. Learn about their features, compliance, and how they perform in extreme conditions for defense applications.

USA Manufactured Parts

Discover high-quality O-rings, rubber, plastic, and metal parts manufactured in the USA. Learn about our commitment to American-made products that meet rigorous quality standards for diverse industries.

Military, Aerospace, & Automotive Materials Available

Click here to see some of our most commonly served industries!

Each of these materials has its own advantages, limitations, and cost implications. The choice of material usually depends on factors like chemical compatibility, temperature, pressure, dynamic or static use, and specification requirements.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Back to Industries Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Sealing technology for military, aerospace, and automotive systems requires more than general chemical and temperature resistance. These industries demand absolute reliability under extreme conditions such as rapid pressure fluctuations, thermal cycling, fuel exposure, and high mechanical loads. Canyon Components provides Kalrez®, Canrez®, Chemraz®, and Parker® O-rings, gaskets, and custom-molded parts that meet these challenges with precision and consistency. Our materials include FFKM, FKM, EPDM, NBR, neoprene, Aflas, fluorosilicone, and silicone, as well as specialty elastomers and fluoropolymers designed for fuel resistance, anti-explosive decompression, and long-term durability. Every product is engineered to meet or exceed industry standards such as AMS, MIL-SPEC, NORSOK, and ISO, ensuring consistent performance in the harshest operational environments. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Which materials are most commonly used for high-performance sealing in these industries?

Material selection depends on environmental exposure and performance requirements. FFKM (Perfluoroelastomer) compounds such as Canrez® and Kalrez® deliver the highest level of chemical and thermal resistance for extreme aerospace and military environments, with certain blends withstanding continuous temperatures above 600°F. FKM (Viton®) offers an excellent balance between fuel resistance and temperature capability, making it ideal for automotive and aviation fuel systems. Silicone and fluorosilicone compounds provide flexibility and low-temperature performance in aerospace cabin pressurization systems and sensor housings. EPDM is used in brake systems and environmental seals that require ozone and steam resistance. Canyon Components also offers Aflas® and HNBR for applications involving sour gas, amines, or high mechanical stress. Each compound is formulated and tested for tensile strength, elongation, and hardness stability under the specific conditions of its intended use. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components ensure compliance with industry standards and specifications?

Canyon Components produces and verifies materials according to globally recognized standards such as AMS 7276, AMS 7277, MIL-DTL-25988, MIL-R-83248, and NORSOK M-710. Each batch undergoes strict quality control testing for hardness, tensile strength, elongation, and compression set. Our materials are also validated for low-outgassing and high-purity performance where required by aerospace and defense customers. Canyon Components maintains complete traceability through every stage of manufacturing, providing Certificates of Conformance, lot-specific test reports, and full compliance documentation. Our engineering and quality assurance teams collaborate with OEMs and government contractors to ensure every seal meets or exceeds performance expectations under regulatory and mission-critical conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What challenges do seals face in aerospace and defense applications?

Aerospace seals are exposed to vacuum, temperature extremes, and aggressive fuels or hydraulic fluids that can degrade unprotected elastomers. Seals must resist jet fuel, Skydrol® hydraulic fluid, synthetic lubricants, and oxidizers while maintaining low compression set and high sealing efficiency. Military seals face similar challenges but often require enhanced durability against shock, vibration, and environmental contaminants. Canyon Components provides materials that remain flexible from cryogenic temperatures to over 600°F, preventing leakage during rapid altitude and temperature transitions. We also offer AED (Anti-Explosive Decompression) resistant compounds for high-pressure systems, ensuring safety and reliability under sudden depressurization or extreme stress events. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How do automotive sealing requirements differ from aerospace and military needs?

Automotive sealing emphasizes long-term endurance and cost efficiency under constant dynamic motion and chemical exposure. Modern engines and electric vehicles demand materials that resist fuels, oils, coolants, and environmental pollutants without deteriorating. Canyon Components’ automotive-grade FKM and HNBR seals provide the elasticity and chemical compatibility needed for engine gaskets, transmission seals, and EGR systems. For electric and hybrid vehicles, we supply silicone and fluorosilicone seals designed for temperature extremes and dielectric isolation. We also support high-performance and motorsport applications with custom FFKM and FKM compounds that withstand both high combustion temperatures and aggressive synthetic fuels. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How are Canyon Components’ aerospace and defense materials tested for reliability?

Reliability testing is fundamental to aerospace and defense applications. Canyon Components conducts extensive validation that includes thermal cycling, pressure testing, compression set measurement, and chemical compatibility analysis with fuels, hydraulic fluids, and oxidizers. Materials intended for flight-critical systems are tested under vacuum and high-temperature conditions to confirm resilience against outgassing and shrinkage. In defense applications, we test for ozone resistance, explosive decompression, and mechanical fatigue. Our testing protocols align with standards such as ASTM D2000, AMS 3217, and MIL-STD-810, ensuring that seals perform consistently through repeated operational cycles. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What role do fluorosilicones and specialty elastomers play in aerospace sealing?

Fluorosilicone elastomers bridge the gap between high-temperature and chemical resistance. They combine silicone’s flexibility with fluorocarbon’s fluid resistance, making them perfect for applications involving fuel, hydraulic fluids, and aviation oils. Canyon Components supplies fluorosilicone O-rings, gaskets, and molded components that retain elasticity at temperatures from -100°F to 400°F depending on the blend. These materials perform exceptionally well in static environments, including flight control systems, environmental seals, and avionics enclosures. For even more demanding conditions, we provide metal-to-rubber bonded seals and spring-energized PTFE assemblies, which combine the strength of metallic reinforcement with the sealing performance of high-purity elastomers. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can Canyon Components supply custom parts and prototypes for aerospace or military systems?

Yes. We specialize in custom-molded and machined components for unique sealing applications that standard parts cannot accommodate. Canyon Components provides rapid prototyping and precision tooling to produce components that meet exact dimensional tolerances and material specifications. Our engineers can reverse-engineer legacy parts, optimize groove designs, and develop new compounds that satisfy modern performance requirements. We also offer short production runs for testing and qualification before full-scale manufacturing. Each prototype is produced under controlled conditions and supplied with supporting documentation for traceability and certification. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Do Canyon Components’ materials perform under extreme temperature and pressure conditions?

Absolutely. Our Canrez FFKM materials operate continuously at temperatures above 600°F while maintaining mechanical stability under high pressures. For cryogenic and vacuum environments, silicone and fluorosilicone compounds maintain flexibility and compression recovery far below freezing temperatures. Canyon Components’ materials are validated to perform under rapid thermal transitions and sustained mechanical stress. Whether the application involves jet engine combustion zones, hydraulic flight systems, or high-pressure automotive pumps, our seals retain their structural integrity and sealing force over long service intervals, preventing leaks and ensuring operational safety. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a trusted partner for high-performance sealing solutions?

Canyon Components combines deep material expertise, precision manufacturing, and full regulatory compliance to deliver seals trusted across military, aerospace, and automotive industries. We provide not only components but complete engineering support, from compound selection to application testing. Our materials are manufactured in certified facilities, tested under real-world conditions, and packaged with full traceability and documentation. Customers rely on Canyon Components for rapid turnaround times, custom solutions, and dependable quality that meets the toughest global standards. Whether supplying flight-qualified O-rings, fuel system gaskets, or high-performance automotive seals, we ensure that every component upholds the strength, precision, and durability demanded by these critical industries. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!