PEEK 3D Printing

PEEK (Polyetheretherketone) is a high-performance thermoplastic known for its outstanding strength, chemical resistance, and exceptional thermal stability. Leveraging the advanced capabilities of 3D printing, PEEK parts can be manufactured rapidly, cost-effectively, and with complex geometries that traditional methods cannot easily achieve. Canyon Components proudly offers PEEK 3D printing services, providing high-quality parts suited for demanding industrial and technical applications.

For detailed material properties, visit our PEEK material page or request a quote today.

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Victrex® PEEK, Ketron® PEEK, TECAPEEK®, Vestakeep®, Semitron® PEEK, KetaSpire® PEEK, SustaPEEK.

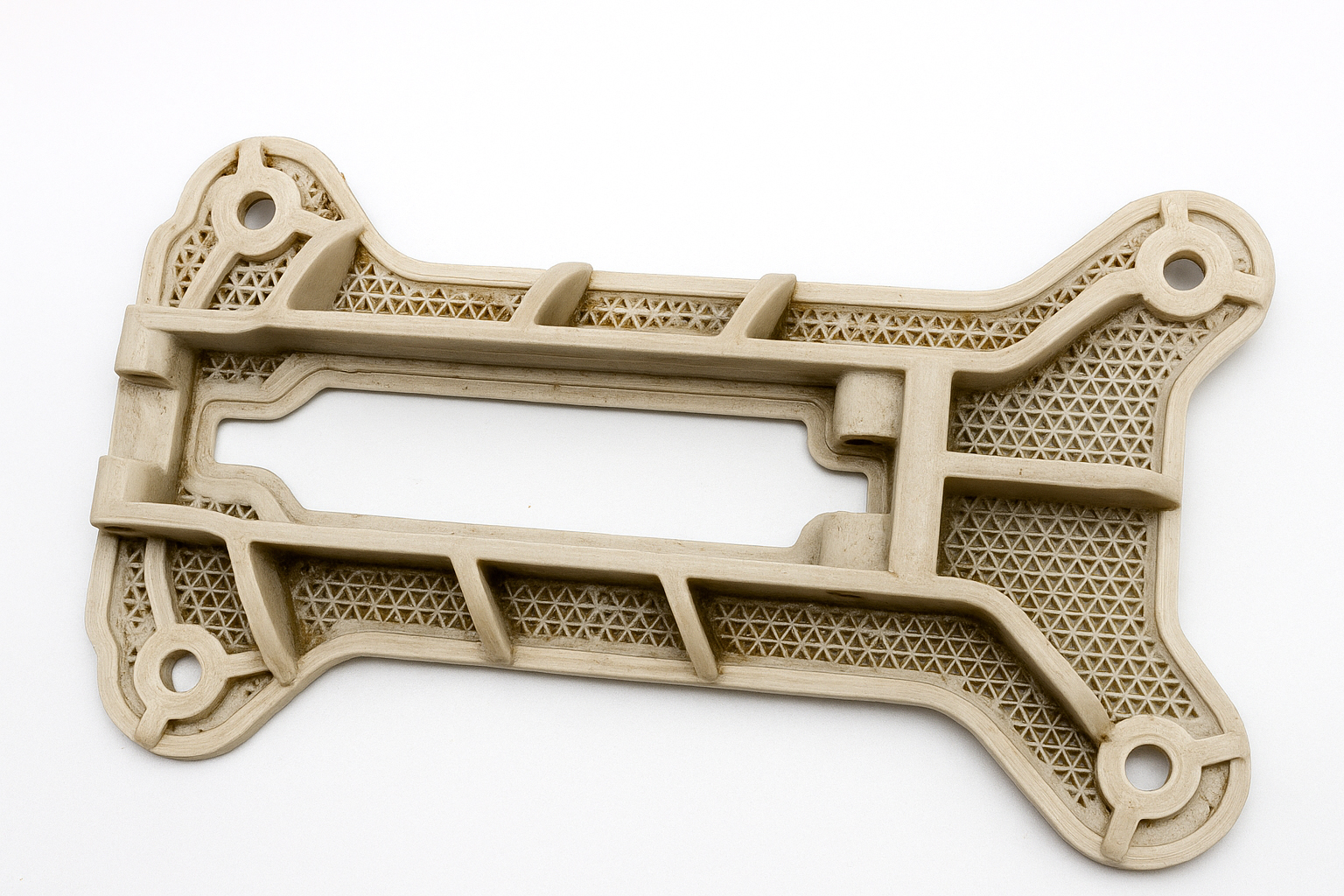

Features of 3D Printed PEEK Parts

- Exceptional Mechanical Strength: Comparable to aluminum, offering superior strength-to-weight ratio ideal for lightweight and durable components.

- High Thermal Stability: Maintains structural integrity in continuous-use temperatures up to 250°C, with short-term use up to 300°C.

- Outstanding Chemical Resistance: Resists most solvents, fuels, oils, acids, and bases, making it suitable for harsh chemical environments.

- Bio-Compatibility: Medical-grade variants of PEEK can be sterilized repeatedly and are FDA and USP Class VI compliant.

- Complex Geometry Capabilities: Enables intricate and complex designs without expensive tooling costs, through the flexibility of 3D printing.

Request a quote for custom PEEK 3D printed parts today.

Common Applications of PEEK 3D Printing

- Aerospace & Defense: Lightweight yet strong components like brackets, structural elements, and housings.

- Medical Devices: Surgical tools, implants, and prosthetics requiring bio-compatibility and sterilization compatibility.

- Automotive: High-performance engine components, sensor housings, and complex under-hood applications.

- Electronics & Semiconductors: Insulators, connectors, and housings for high-temperature electronics.

- Oil & Gas: Components such as valve seats, seals, and pump parts requiring chemical resistance and durability.

Explore our full capabilities on our PEEK page, or directly request a quote.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Specialty Variants of PEEK for 3D Printing

- Carbon-Fiber Reinforced PEEK: Enhanced stiffness and strength for load-bearing parts and structural applications.

- Glass-Filled PEEK: Improved dimensional stability and rigidity, suitable for high-temperature mechanical components.

- Medical-Grade PEEK: Certified materials that meet FDA and USP Class VI standards, ideal for medical applications involving patient contact.

To learn more, check out our PEEK material page, or request a quote for specialized PEEK variants.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Pros and Cons of PEEK 3D Printing

At Canyon Components, we offer industry-leading expertise in PEEK and additive manufacturing, delivering customized, high-performance parts for the most challenging industrial environments. Whether your project demands intricate aerospace components, medical-grade implants, or robust oil and gas equipment, our PEEK 3D printing capabilities will exceed your expectations.

Ready to begin your project? Explore more on our PEEK materials page, or quickly request a quote to connect with our experts today.

Pros of 3D Printed PEEK Parts

- Rapid prototyping and production of high-performance parts.

- Eliminates expensive molds or tooling costs.

- Enables complex geometries and internal channels not achievable through traditional machining.

- Lightweight with outstanding thermal, chemical, and mechanical properties.

Request a quote for custom PEEK 3D printed parts today.

Cons of PEEK 3D Printing

- Higher raw material costs compared to standard plastics.

- Requires specialized equipment and controlled processing conditions.

- Surface finish may require additional post-processing for specific applications.

Discover more about our process on our 3D printing page, or directly request a quote.

Back to Plastics Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More