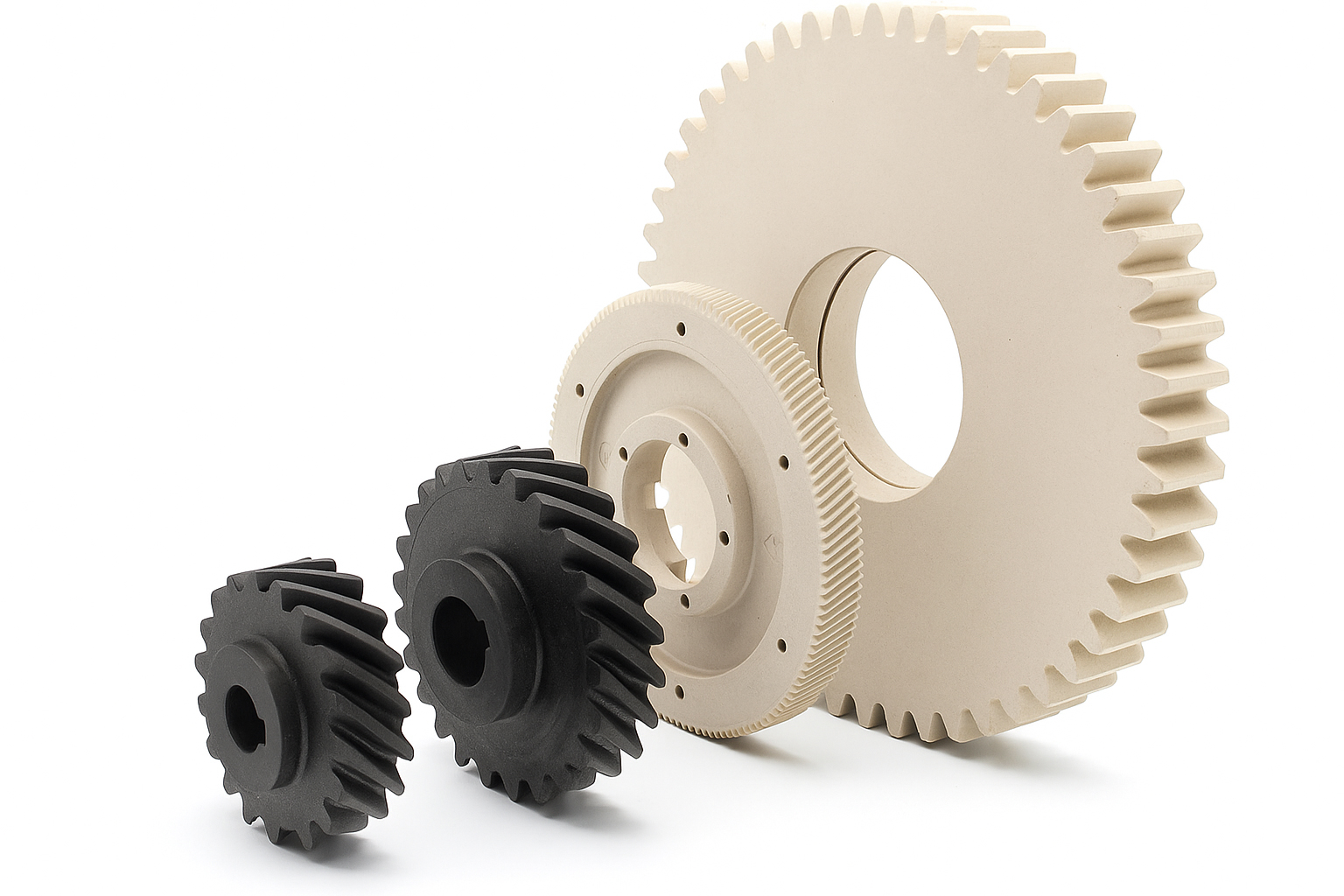

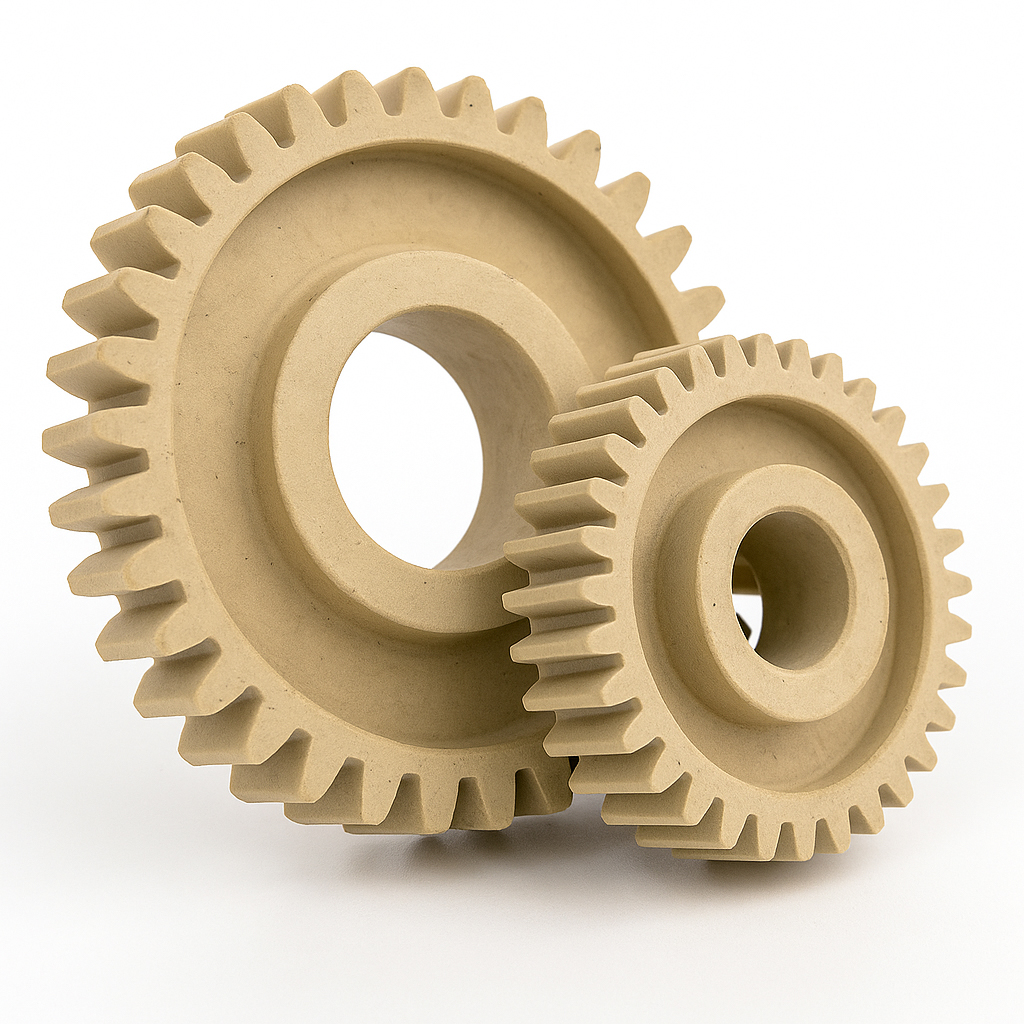

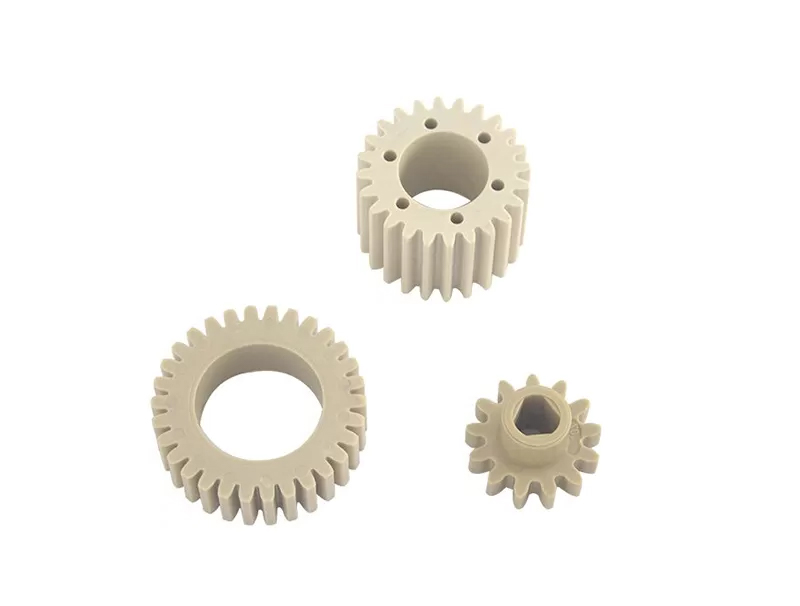

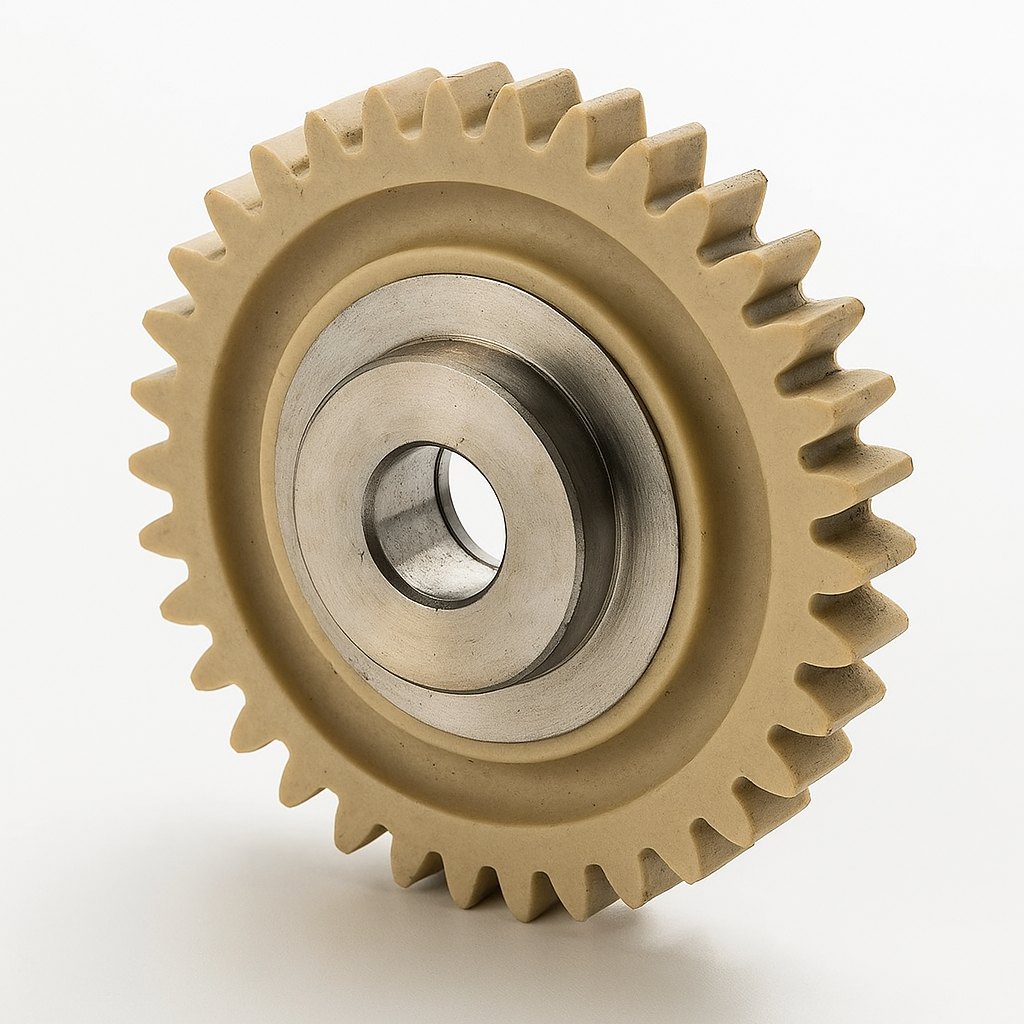

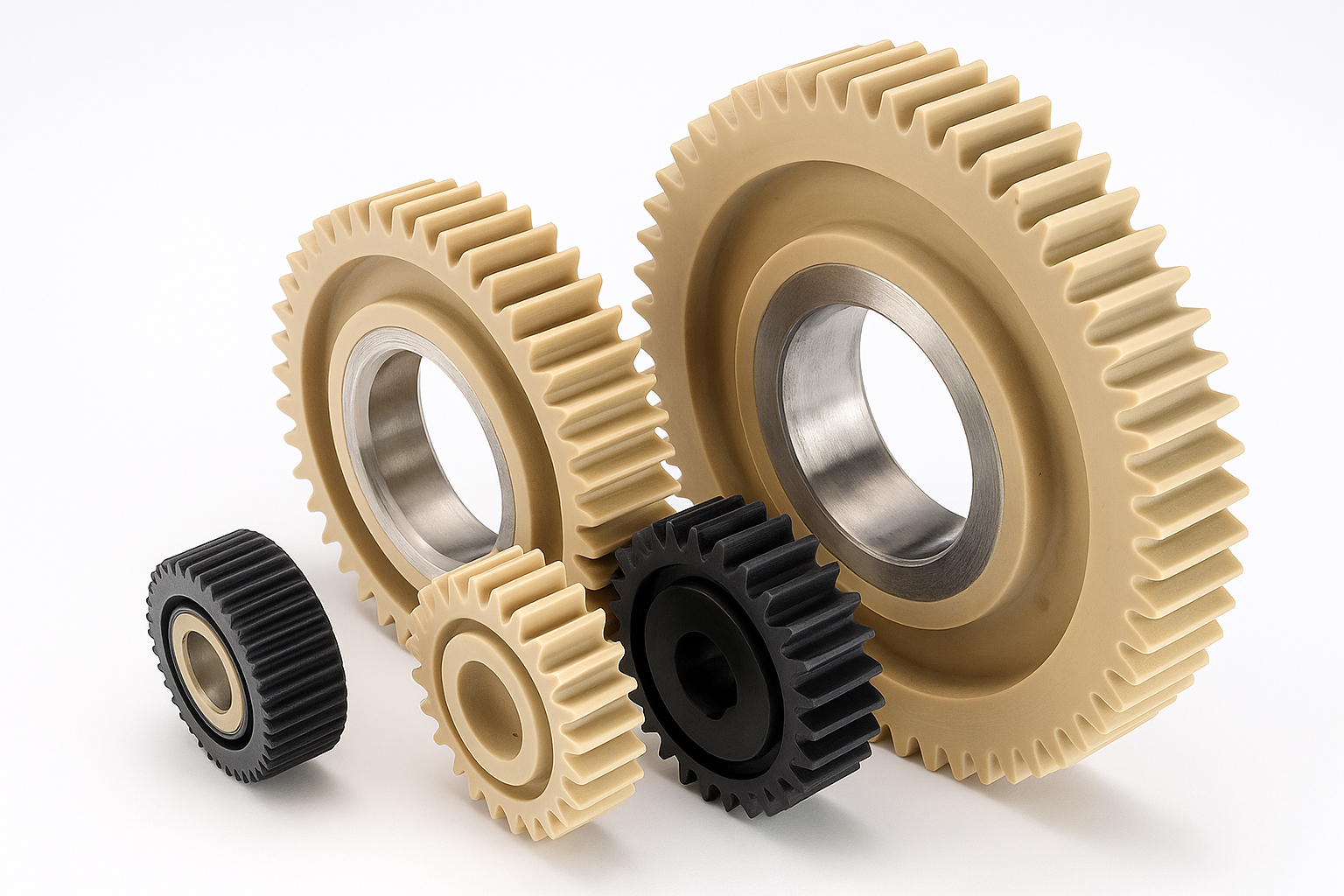

PEEK Gears & Bearings

Polyetheretherketone (PEEK) is a premier choice for manufacturing high-performance gears and bearings that must endure demanding mechanical, thermal, and chemical conditions. At Canyon Components, we offer both standard and custom-engineered PEEK gears and bushings designed for critical applications in aerospace, medical, semiconductor, and industrial machinery. PEEK's ability to maintain dimensional integrity, resist wear, and perform under thermal and chemical stress makes it an ideal replacement for metal and lower-grade plastics in precision motion and support components.

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Keywords: PEEK raw material, high-performance thermoplastic, PEEK plastic resin, PEEK granules, medical-grade PEEK, industrial PEEK polymer, unfilled PEEK, carbon-filled PEEK, bearing-grade PEEK, PEEK gears, PEEK bushings, wear-resistant thermoplastics, high-temperature plastic bearings, PEEK bearings, PEEK components, engineered thermoplastics for motion control

PEEK Material Advantages

PEEK offers a unique combination of tribological and mechanical benefits:

- Low Coefficient of Friction: Naturally slick surface minimizes wear and heat generation.

- High PV (Pressure-Velocity) Limits: Sustains high rotational speeds under load.

- Self-Lubricating Grades: Filled versions with PTFE, graphite, or carbon fiber reduce the need for external lubricants.

- Excellent Dimensional Stability: Minimal creep under load and low thermal expansion ensure tight tolerances.

- Thermal and Chemical Resistance: Operates in continuous service temperatures up to 260°C (500°F) and withstands aggressive chemicals, steam, and cleaning agents.

Machined vs. Molded Gears and Bearings

Canyon Components supports both precision machining and injection molding of PEEK gears and bushings:

- Machined PEEK Parts: Ideal for low to mid-volume production, prototypes, and applications requiring ultra-tight tolerances or complex geometries. CNC machining allows for quick turnaround and design flexibility.

- Molded PEEK Parts: Best for high-volume production, molded components reduce per-part cost and can include integrated design features like self-centering hubs or lubrication grooves.

Our team can advise on the most cost-effective and performance-appropriate method for your specific project.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Industry Applications

PEEK gears and bushings are trusted in sectors that require high precision and resistance to wear, chemicals, and temperature extremes:

- Aerospace: Actuator gears, flap drive components, and environmental control systems

- Chemical Processing: Pump bushings, agitator bearings, and chemical valve gear sets

- Semiconductor & Vacuum Systems: Outgassing-resistant, non-contaminating bearings and drive gears

- Medical Devices & Robotics: Surgical tool bushings, motion control gears, and components for MRI-safe and sterilizable equipment

- Energy & Industrial Equipment: Turbine support gears, compressor bearings, and cryogenic mechanisms

Specialty Variants

We offer a wide range of bearing-grade PEEK formulations engineered to meet specific performance goals:

- PTFE-Filled PEEK: Low friction and excellent wear resistance for dry-running conditions

- Graphite-Filled PEEK: Enhanced thermal stability and lubrication at higher temperatures

- Carbon Fiber-Filled PEEK: Increased strength, stiffness, and dimensional accuracy under load

- Custom Compound Blends: Formulated for high-load, high-speed, or FDA/medical-grade compliance

Why Choose Canyon Components

These specialty compounds allow engineers to tailor performance for applications involving extreme speeds, prolonged use, or minimal maintenance requirements.

Canyon Components is ready to support your project from material selection to final production. Whether you're developing a custom gear for aerospace actuators or sourcing high-precision bushings for a vacuum pump, we deliver engineered solutions backed by deep material expertise.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Back to Plastics Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More