Plastics

Plastics are a broad class of synthetic or semi-synthetic materials known for their versatility and moldability. They are crucial in numerous applications due to their ability to be shaped, lightweight nature, and resistance to chemicals and moisture.

Highlighted below are the diverse types of plastics available through Canyon Components. Each type of plastic has a dedicated page that delves into its scientific composition, properties, and wide-ranging uses, illuminating the essential role these materials play in both specialized and everyday settings.

Each plastic type encompasses a variety of sub-materials tailored for specific applications. From high-impact resistance to thermal insulation, from biodegradable options to those suitable for medical use; Canyon Components caters to an extensive array of requirements, providing solutions for any plastic material need.

The engineers and consultants here at Canyon Components take pride in finding the perfect solution our customer’s needs. Contact our expert staff for assistance with any seal or application questions!

Materials

PEEK (Polyetheretherketone)

PEEK plastic, or polyether ether ketone, is a high-performance thermoplastic known for its exceptional heat resistance, chemical stability, and mechanical strength. It's widely used in aerospace, medical implants, and automotive industries for its durability and ability to withstand harsh environments.

PTFE (Polytetrafluoroethylene, Teflon)

Polytetrafluoroethylene (PTFE) Plastic, commonly known as Teflon, is a highly non-reactive and low-friction thermoplastic. Renowned for its outstanding chemical resistance, heat tolerance, and electrical insulation properties, it's extensively used in cookware coatings, electrical insulation, and various industrial applications.

PMMA (Polymethyl Methacrylate)

Polymethyl Methacrylate (PMMA) Plastic, commonly known as acrylic or Plexiglas, is a transparent thermoplastic with glass-like clarity and excellent light transmission. It's durable, shatter-resistant, and used in applications like lenses, aquariums, signage, and various architectural features due to its weather-resistant properties.

POM (Polyoxymethylene, Acetal)

Polyoxymethylene (POM) Plastic, also known as Acetal or Delrin, is a high-strength, low-friction thermoplastic. It's characterized by its dimensional stability, excellent wear resistance, and low moisture absorption, making it ideal for precision parts in automotive and consumer electronics.

Nylon (Polyamide, PA)

Nylon, a synthetic thermoplastic polymer, is renowned for its high strength, elasticity, and abrasion resistance. It's versatile, easily dyeable, and used in a wide range of products from textiles and ropes to gears and automotive parts.

ABS (Acrylonitrile Butadiene Styrene)

ABS plastic, a thermoplastic polymer blend of acrylonitrile, butadiene, and styrene, is renowned for its toughness, impact resistance, and rigidity. It's easily machinable and ideal for automotive parts, consumer goods, and 3D printing due to its strength and versatility.

PBT (Polybutylene Terephthalate)

PBT (Polybutylene Terephthalate) is a durable, heat-resistant thermoplastic with excellent electrical properties. It's known for its strength, stiffness, and stability under heat, widely used in electrical components, automotive parts, and consumer goods.

PC (Polycarbonate)

Polycarbonate (PC) Plastic is a tough, transparent thermoplastic with exceptional impact resistance, heat tolerance, and optical clarity. Its versatility makes it ideal for bulletproof glass, eyewear lenses, medical devices, and protective gear, offering a unique balance of strength and lightweight properties.

PC/ABS (Polycarbonate ABS Blend)

PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) Plastic is a robust blend combining the heat resistance and mechanical strength of polycarbonate with the flexibility and high-quality finish of ABS. Ideal for automotive, electronics, and consumer goods, it offers excellent impact resistance and durability.

PC/ASA (Polycarbonate ASA Blend)

PC/ASA plastic, a blend of polycarbonate and acrylonitrile styrene acrylate, offers superior UV resistance, high heat stability, and excellent mechanical properties. Ideal for outdoor applications, it combines durability with aesthetic appeal and is widely used in automotive and electronics industries.

PET (Polyethylene Terephthalate)

Polyethylene Terephthalate (PET) is a durable, lightweight thermoplastic, renowned for its clarity, strength, and recyclability. Widely used in beverage bottles, food packaging, and textiles, PET is also food-safe, resistant to water and many chemical solvents, and easily formed into various shapes.

PETG (Polyethylene Terephthalate Glycol)

PETG plastic, a glycol-modified version of polyethylene terephthalate, is valued for its clarity, excellent chemical resistance, and thermoformability. It's a popular choice for 3D printing, packaging, and medical devices due to its durability, impact resistance, and ease of fabrication.

Polyethylene (PE)

Polyethylene (PE) plastic, renowned for its versatility, is a widely used thermoplastic. It's lightweight, impact-resistant, and has excellent chemical resistance. Commonly used in packaging, containers, and pipes, PE is available in varying densities for different applications, including high and low-density forms.

PP (Polypropylene)

Polypropylene (PP) plastic, known for its exceptional chemical resistance and durability, is a lightweight thermoplastic. It's resilient against fatigue, has a high melting point, and is ideal for packaging, automotive parts, and textiles, thanks to its versatility and recyclability.

PPSU (Polyphenylsulfone)

Polyphenylsulfone (PPSU) Plastic is a high-performance thermoplastic known for its exceptional heat resistance, toughness, and stability under thermal stress. It's widely used in medical instruments, aerospace, and plumbing components due to its excellent chemical resistance and ability to withstand repeated sterilizations.

PS (Polystyrene)

Polystyrene (PS) plastic, a versatile and cost-effective thermoplastic, is known for its rigidity, clarity, and insulating properties. Widely used in packaging, disposable tableware, and insulation, PS is available in both solid and foam forms, catering to a broad range of applications.

PVC (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) plastic, a widely utilized thermoplastic, is celebrated for its durability, chemical resistance, and versatility. It's commonly used in construction for pipes and fittings, medical devices, and window frames, and can be made more flexible with the addition of plasticizers.

SAN (Styrene Acrylonitrile)

Styrene Acrylonitrile (SAN) plastic is a copolymer blend known for its clarity, rigidity, and resistance to chemicals and heat. It combines the strength of polystyrene with the toughness of acrylonitrile, making it ideal for household and commercial items like containers and kitchenware.

Product Types

All Products

Explore our full range of products, including gaskets, O-rings, screws, custom parts, and more. Discover high-quality components designed to meet the needs of various industrial applications.

Fasteners

Explore a wide range of standard and custom fasteners designed for diverse applications in industries such as construction, automotive, and electronics. Learn about their features, materials, and how to select the right fastener for your specific needs.

Standard and Custom Kitting

Learn about our standard and custom kitting services for O-rings, gaskets, and custom parts, designed to streamline assembly and reduce downtime. Discover how our tailored kits meet your specific project requirements.

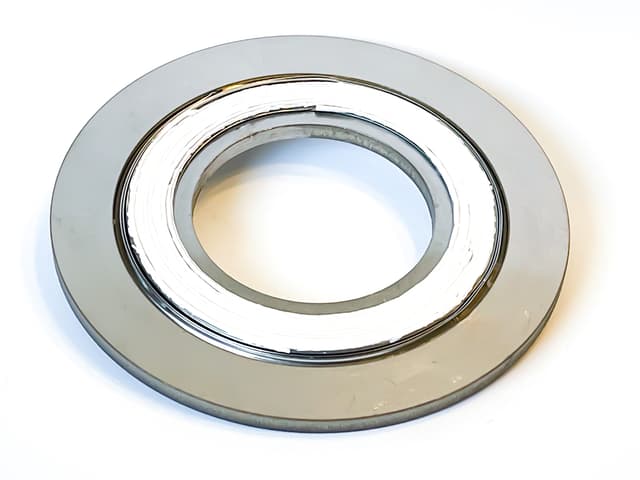

Spiral Wound Gaskets

Discover the advantages of spiral wound gaskets, designed for high-pressure and high-temperature applications. Learn about their construction, common uses, and how they provide reliable sealing in demanding environments.

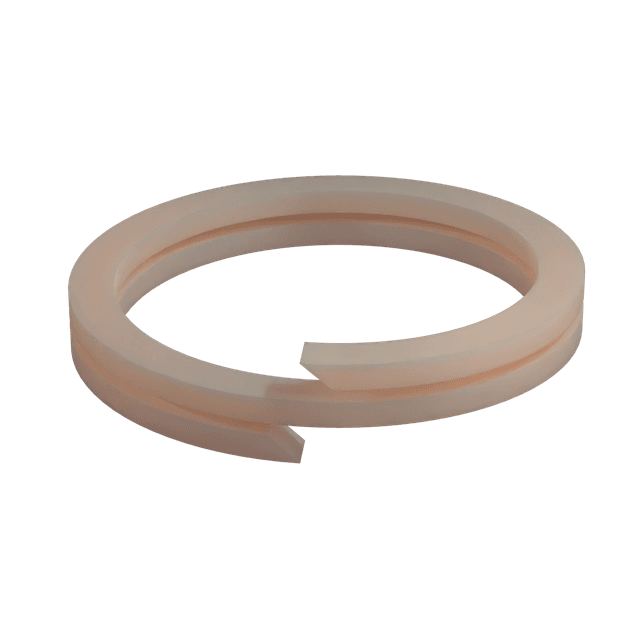

Backup Rings

Explore backup rings, essential components that enhance O-ring performance in high-pressure applications. Learn about their types, materials, selection criteria, and best practices for installation and maintenance to prevent seal extrusion.

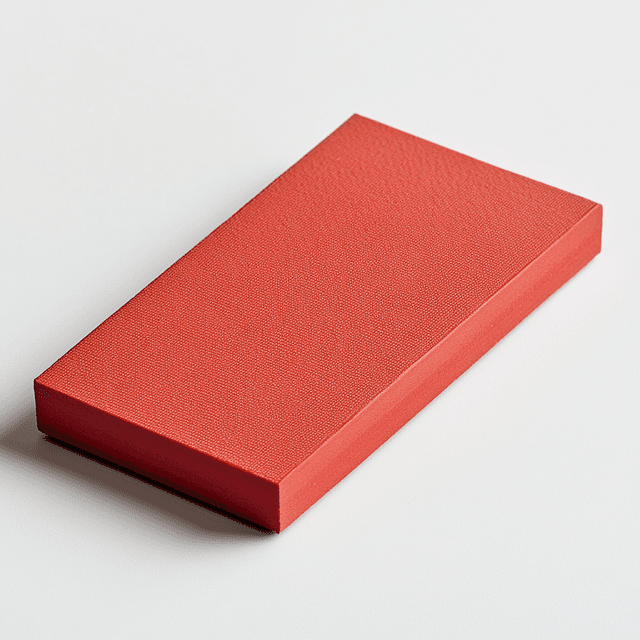

High-Performance Foam and Sponge Materials

Explore high-performance foam and sponge materials designed for superior cushioning, insulation, and sealing. Learn about their features, common applications, and how they provide reliable performance in demanding environments.

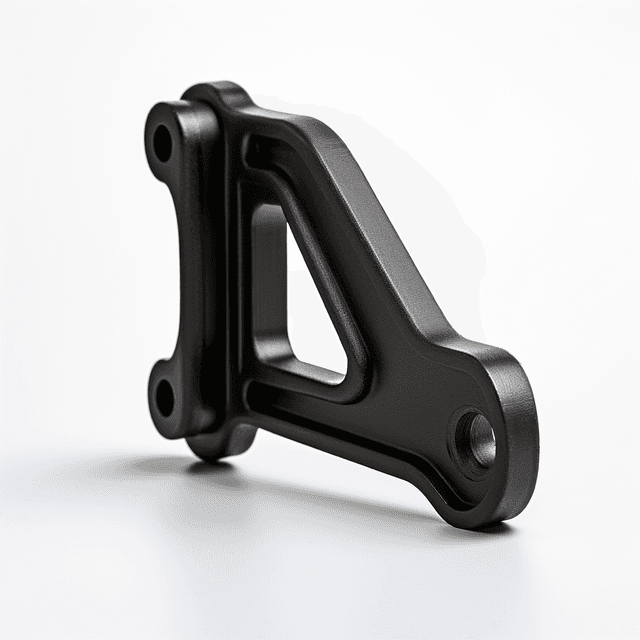

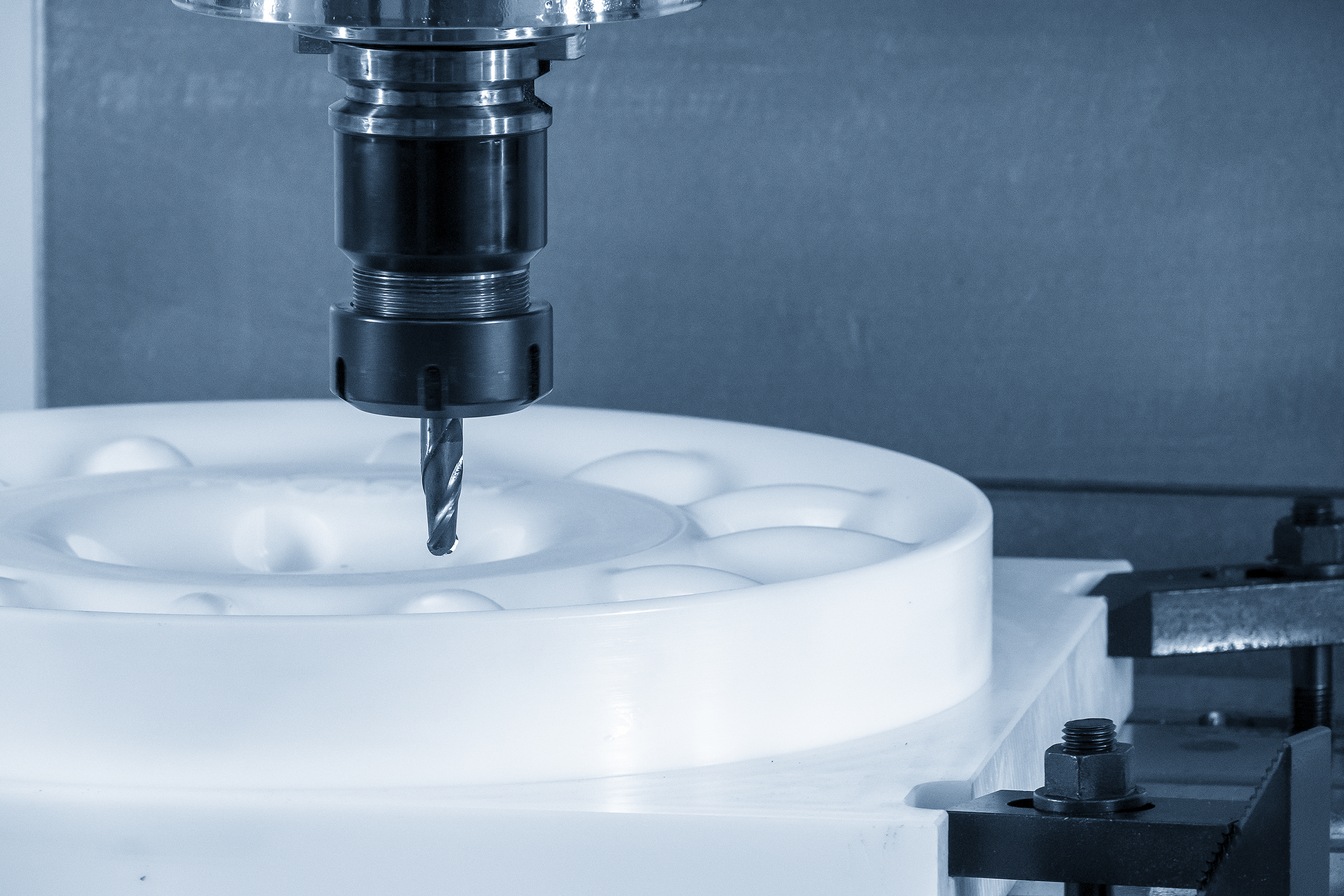

Custom Plastic Parts

Discover custom plastic parts designed for your unique specifications. Learn about our advanced manufacturing processes, material options, and how we provide reliable, high-quality plastic components for various industries.

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Plastics are some of the most versatile materials in modern engineering, offering an exceptional balance of strength, precision, and chemical resistance. From lightweight structural components to precision seals, plastics play a crucial role in industries ranging from aerospace to semiconductor manufacturing. Each material, whether PTFE, PEEK, Nylon, UHMW, or Acetal, offers its own balance of performance characteristics for specific environments. At Canyon Components, our engineering team helps customers select the right plastic for their needs, offering design assistance, prototyping, and manufacturing services to ensure performance, reliability, and cost-efficiency. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the main types of plastics offered by Canyon Components?

Canyon Components supplies a wide range of plastics, including PTFE, PEEK, Acetal, Nylon, and UHMW. PTFE offers outstanding chemical resistance and the lowest friction coefficient of any solid material. PEEK is a high-performance thermoplastic known for strength and high-temperature capability. Acetal (Delrin®) provides excellent dimensional stability, Nylon offers wear resistance and toughness, and UHMW delivers superior impact and abrasion resistance. Each can be machined or molded for tight-tolerance applications. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What industries rely on plastic components?

Virtually every industry benefits from advanced plastic materials. Aerospace and defense manufacturers use high-strength, lightweight plastics to reduce weight without compromising reliability. Medical and pharmaceutical sectors require biocompatible, sterilization-resistant materials. Semiconductor and electronics industries depend on ultra-clean, low-outgassing plastics like PEEK and PTFE. Food, beverage, and water systems rely on FDA, NSF, and 3A-compliant plastics for sanitary performance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How are plastic parts manufactured at Canyon Components?

Plastic components are produced through several precision manufacturing methods, including CNC machining, injection molding, extrusion, and compression molding. CNC machining is ideal for tight tolerances or small production runs, while injection molding suits higher-volume parts. Canyon Components also provides cutting, forming, and post-machining services to ensure that every component meets customer specifications and dimensional accuracy requirements. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are the key performance advantages of engineering plastics?

Engineering plastics combine strength, low weight, corrosion resistance, and excellent electrical insulation. They can often replace metals in demanding applications, reducing cost and simplifying maintenance. Many plastics exhibit low friction, making them ideal for sliding, rotating, or dynamic assemblies. With thermal and chemical stability, plastics can operate in environments that would degrade or corrode other materials, extending service life and improving system reliability.

Can plastics handle high temperatures or extreme conditions?

Yes. Many engineering plastics are designed to perform in harsh environments. PEEK can withstand continuous use above 480°F, PTFE remains stable to 500°F, and Acetal operates reliably in moderate thermal ranges. Specialized blends and reinforced plastics can resist radiation, cryogenic temperatures, and high pressures. Canyon Components assists customers in selecting the right grade based on their required temperature range and operating environment. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Are plastic materials resistant to chemicals and corrosion?

Chemical resistance varies by polymer type. PTFE and PEEK provide near-universal resistance to acids, bases, and solvents, while Acetal and Nylon perform well in hydrocarbons and mild chemicals. UHMW resists most corrosive media and provides excellent performance in wet, abrasive conditions. Canyon Components maintains detailed chemical compatibility data to help customers identify safe and long-lasting materials for each application.

Can plastics be used in FDA, medical, or sanitary environments?

Yes. Canyon Components offers a range of FDA CFR 21.177, USP Class VI, and NSF-compliant plastics suitable for medical, pharmaceutical, food, and potable water use. Materials like PTFE, PEEK, and Acetal can be supplied with full traceability and certifications. Our cleanroom manufacturing and packaging options further ensure that parts remain free of contaminants throughout production and delivery.

Can plastic components be customized for specific applications?

Absolutely. Canyon Components provides custom-machined, injection-molded, and extruded plastic parts built to precise dimensional and performance specifications. Our team supports everything from prototype development to full-scale production, offering design for manufacturability, tolerance analysis, and material selection assistance. Specialty additives, fillers, or reinforcements can also be incorporated to enhance wear resistance or conductivity. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What value does Canyon Components provide beyond plastic material supply?

Canyon Components delivers end-to-end support for plastic-based components, sealing, and structural solutions. Our team assists with material testing, reverse engineering, and compliance documentation to ensure every product meets regulatory and performance standards. With experience across industries and materials, we help customers streamline development, reduce downtime, and achieve consistent, high-quality performance in every application. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!