Compliances

Compliance is a critical aspect of ensuring the safety, reliability, and performance of the materials and components used in a wide range of industries, from food and beverage to pharmaceuticals and aerospace.

Below is a list of many of the compliance standards that Canyon Components adheres to. Each compliance page provides detailed information on the standards, regulations, and testing procedures that our materials meet, ensuring they are safe, durable, and effective in their respective applications.

Whether you're working with FDA, NSF, or NORSOK standards, Canyon Components offers materials that meet the strictest regulatory requirements, helping you achieve compliance and success in even the most demanding environments.

The engineers and consultants here at Canyon Components take pride in finding the perfect solution our customer’s needs. Contact our expert staff for assistance with any seal or application questions!

Table of Contents

Food & Dairy

Food and Dairy Materials

Explore FDA Compliant and 3A Materials: designed for food and dairy industries, ensuring hygiene and safety.

FDA Compliant Materials

Discover FDA compliant materials for food, medical, and pharmaceutical use, meeting strict safety standards.

NSF 51 Materials

Discover NSF 51 materials for food equipment, ensuring safety, regulatory compliance, hygiene, and durability.

USDA 3A Materials

Explore USDA 3A materials for dairy and food processing, ensuring hygiene, safety, and USDA compliance.

EU 1935/2004 Materials

Explore EU 1935/2004 materials for food contact, ensuring safety, hygiene, and compliance with regulations.

Medical & Pharmaceutical

Medical and Pharmaceutical Materials

Discover Medical & Pharmaceutical Materials: ensuring safety, compliance, and performance in devices and drug manufacturing.

USP Class VI Materials

Explore USP Class VI materials for medical devices, pharmaceuticals, and food processing, ensuring safety and purity.

ISO 10993-1

Discover ISO 10993-1 materials, certified for biocompatibility in medical devices, ensuring safety and performance.

Vacuum Baking & Cleaning

Explore our specialized services: vacuum baking for material degassing, ultrasonic cleaning for precision parts, and custom bagging for product protection. Request a quote today!

Clean Room Manufactured Materials

Discover clean room manufactured material features, applications, and how they meet strict cleanliness standards in medical, pharmaceutical, and semiconductor environments.

Semiconductor & Solar

Semicon and Solar Materials

Discover materials for semiconductor and solar applications: specialized for manufacturing and durability in advanced energy systems.

Vacuum Baking & Cleaning

Explore our specialized services: vacuum baking for material degassing, ultrasonic cleaning for precision parts, and custom bagging for product protection. Request a quote today!

Clean Room Manufactured Materials

Discover clean room manufactured material features, applications, and how they meet strict cleanliness standards in medical, pharmaceutical, and semiconductor environments.

Oil Field & High Pressure

Oil Field Materials

Explore materials for oil field applications: durable, resistant, and engineered to withstand harsh energy operations.

API 6A Materials

Discover API 6A materials for oil and gas, ensuring compliance and reliable performance in extreme conditions.

NORSOK M-710 Materials

Explore NORSOK M-710 anti-explosive decompression materials for oil and gas, ensuring reliability and compliance in harsh environments.

NACE TM0297 Materials

Discover NACE TM0297 anti-explosive decompression materials for sour gas applications, ensuring corrosion resistance, durability, and compliance.

Drinking Water

Drinking Water Materials

Discover materials for drinking water: certified, safe options meeting rigorous health standards for distribution and storage.

NSF 61 Materials

Explore NSF 61 materials for drinking water systems, ensuring safety, compliance, and clean water in applications.

WRAS Materials

Explore WRAS materials for potable water systems, ensuring safety, compliance, and integrity across industries.

KTW Materials

Discover KTW materials for drinking water systems, ensuring safety, compliance, and reliability in potable applications.

Electronics EMI & RFI Shielding

EMI and RFI Shielding Materials

Explore CanGuard EMI & RFI Shielding materials, designed to protect electronics from interference and ensure reliable performance in sensitive applications.

Vacuum Baking & Cleaning

Explore our specialized services: vacuum baking for material degassing, ultrasonic cleaning for precision parts, and custom bagging for product protection. Request a quote today!

Clean Room Manufactured Materials

Discover clean room manufactured material features, applications, and how they meet strict cleanliness standards in medical, pharmaceutical, and semiconductor environments.

Military, Aerospace, & Automotive

Military, Aerospace, and Automotive Materials

Explore materials for military, aerospace, and automotive applications, designed for strength, precision, and durability in extreme conditions.

Glossary of Specifications

Explore our Glossary of Specifications, offering clear definitions and explanations of key industry standards and certifications. Learn how these specifications impact material selection and compliance in various industries.

AMS (Aerospace Material Specification)

Learn about AMS (Aerospace Material Specification) materials, designed to meet rigorous standards for aviation and aerospace industries. Discover their features, compliance, and how they ensure performance and safety in critical applications.

Mil-Spec Elastomeric Materials

Discover Mil-Spec elastomeric materials, engineered to meet stringent military specifications for strength, durability, and precision. Learn about their features, compliance, and how they perform in extreme conditions for defense applications.

USA Manufactured Parts

Discover high-quality O-rings, rubber, plastic, and metal parts manufactured in the USA. Learn about our commitment to American-made products that meet rigorous quality standards for diverse industries.

UL Certified

UL Certified Materials

Explore UL Certified Materials, rigorously tested for safety and performance, meeting strict standards for reliability across industries.

UL 157 Elastomeric Materials

Explore UL 157 elastomeric materials, certified for sealing applications requiring fire resistance and durability. Learn about their features, compliance with UL standards, and how they ensure reliable performance in critical environments.

Chemical Processing

Chemical Processing Materials

Discover high-performance O-rings for chemical processing applications and optimal performance in harsh industrial environments.

Chemical Compatibility Table

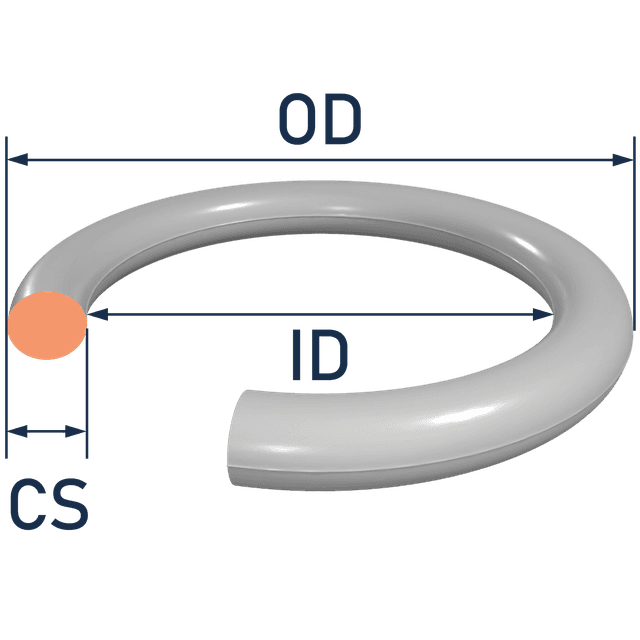

The successful implementation and performance of O-rings, gaskets, and custom molded parts heavily depend on the material compatibility of the components.

Miscellaneous Specifications

General Purpose Materials

Discover General Purpose Materials, versatile and cost-effective options for a wide range of applications in manufacturing, processing, and construction.

ASTM D2000 Elastomeric Materials

Explore ASTM D2000 elastomeric materials, designed to meet industry standards for performance and durability.

O-Ring Rubber Shelf Life

Learn about the shelf life of O-ring rubber materials, factors affecting longevity, and best storage practices to maintain sealing performance. Ensure your O-rings stay reliable and effective over time.

Vacuum Baking & Cleaning

Explore our specialized services: vacuum baking for material degassing, ultrasonic cleaning for precision parts, and custom bagging for product protection. Request a quote today!

Clean Room Manufactured Materials

Discover clean room manufactured material features, applications, and how they meet strict cleanliness standards in medical, pharmaceutical, and semiconductor environments.

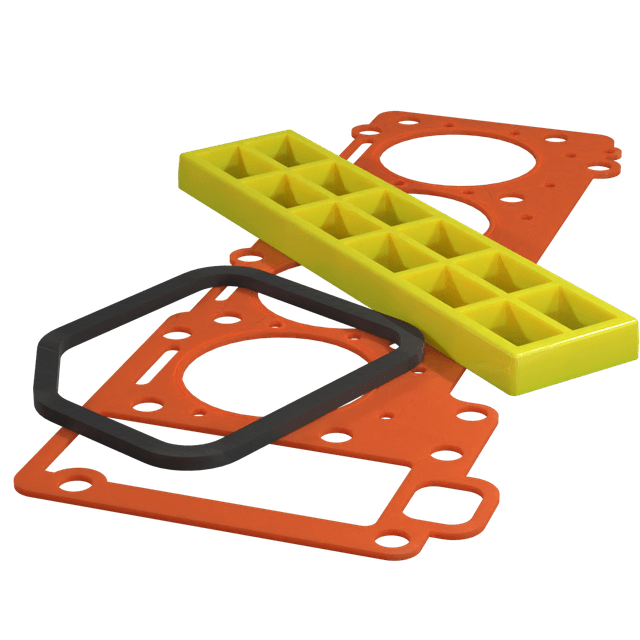

Product Types

Custom Parts

Here at Canyon Components, we make sure to offer our customers any manufacturing technique they desire. Whether your O-rings, gaskets, & custom molded parts be rubber, plastic, or metal, rest assured that Canyon Components can make it!

Gaskets & Custom Cutting

Whether your custom cut parts be rubber, plastic, sponge, composite, or metal, rest assured that Canyon Components can make it! Canyon Components strives to meet all customer service requests. If you need something that isn't listed, feel free to contact a Canyon Components product and application consultant.

Infinite "Giant" Diameter O-Rings

By either Continuous Molding O-rings, or Splice & Vulcanizing O-rings, Canyon can provide mold-less, infinitely large O-rings at competitive prices!

Specialty Compliances

Canyon have materials available for O-rings, gaskets, & custom parts with compliances ranging from USP Class VI <87> & <88> for medical applications, to FDA CFR 21.177.2600 grades A through F for different food types, to the various drinking water specifications like KTW and NSF. Whether it's metal, rubber, or plastic, Canyon can meet your needs!

Back to Products Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More

FAQ

Compliance is essential in every industry that depends on precision materials and safe, reliable performance. Whether sealing systems for food processing, medical equipment, or aerospace assemblies, each application must meet strict regulatory and material standards. Canyon Components’ Compliance Hub brings together all the major certifications in one place, including FDA, NSF, WRAS, NORSOK, and USP Class VI. Our materials are tested and validated to meet or exceed international requirements, and our engineering team can help interpret these standards to ensure your parts achieve full compliance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What does FDA compliance mean for sealing materials?

FDA compliance refers to the United States Food and Drug Administration’s requirements for materials that contact food or pharmaceuticals. The relevant standard, FDA CFR 21.177.2600, outlines allowable ingredients and testing methods for rubber compounds used in food contact. Canyon Components supplies FDA-compliant O-rings and gaskets in materials such as silicone, EPDM, FKM, and FFKM, all designed to withstand cleaning chemicals, high heat, and continuous operation in sanitary systems. Each batch can be supplied with traceable documentation verifying compliance. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What are NSF 51 and NSF 61, and how do they differ?

Both NSF 51 and NSF 61 were developed by NSF International to ensure materials are safe for food and water contact, but they apply to different environments. NSF 51 focuses on materials used in food equipment like mixers and dispensers, while NSF 61 covers components in drinking water systems. Canyon Components offers O-rings, gaskets, and seals tested and certified to both standards, helping customers maintain regulatory compliance and ensure long-term material stability in wet or sanitary environments.

What is WRAS approval, and why is it important for water systems?

WRAS (Water Regulations Advisory Scheme) approval verifies that materials and components used in potable water systems will not contaminate or alter water quality. This certification is required in the United Kingdom and recognized internationally. Canyon Components supplies WRAS-approved EPDM and FKM materials designed to resist chloramine, hot water, and cleaning agents. Our products are tested under strict laboratory conditions to ensure they meet WRAS’s mechanical and chemical standards for long-term performance.

How does USP Class VI testing apply to medical and pharmaceutical materials?

USP Class VI testing evaluates the biocompatibility of materials by exposing them to biological and chemical tests to confirm that no harmful reactions occur. Materials that meet USP <88> and USP <87> are proven safe for contact with living tissue and fluids. Canyon Components provides USP Class VI certified elastomers and plastics that are widely used in medical devices, tubing, and pharmaceutical processing equipment. We also offer full material traceability and cleanroom packaging to support validation in regulated environments. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What does NORSOK M-710 certification indicate about a material?

NORSOK M-710 is a rigorous standard developed for the oil and gas industry to evaluate material resistance to explosive decompression and chemical degradation. This standard ensures that seals maintain elasticity and structural integrity when exposed to rapid gas decompression or harsh fluids such as sour gas. Canyon Components provides AED-resistant FKM, FFKM, and HNBR compounds qualified to NORSOK M-710. These materials are designed to prevent blistering, cracking, or swelling under extreme subsea and high-pressure operating conditions. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

How does Canyon Components verify compliance with international standards?

Verification involves both material testing and supplier certification. Canyon Components sources compounds and raw materials that are independently tested and certified according to ASTM, ISO, or other global standards. Our quality control system maintains documentation, traceability, and inspection records for each batch. Customers can request certificates of conformance, lot traceability, and test reports for every compliant part we supply, ensuring full transparency from material formulation to final delivery. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

Can a single material meet multiple compliance standards?

Yes, many high-performance elastomers and plastics can meet multiple certifications simultaneously. For example, a single EPDM or FKM compound may be FDA, NSF 61, and WRAS compliant, while a medical-grade silicone may also meet USP Class VI and ISO 10993 requirements. Canyon Components helps customers identify materials that offer the widest possible range of compliance, reducing the need for multiple formulations and simplifying inventory management.

How do compliance standards vary between industries?

Compliance requirements differ depending on exposure, safety, and environmental regulations. Food and beverage processing focuses on sanitation and non-toxicity, medical and pharmaceutical sectors prioritize biocompatibility and sterilization stability, and oil and gas industries emphasize resistance to pressure and chemical attack. Canyon Components tailors its material selection and documentation to each sector’s specific regulations, ensuring that customers meet all relevant domestic and international compliance obligations. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!

What makes Canyon Components a trusted partner for compliance-driven projects?

Canyon Components combines material expertise with a deep understanding of regulatory requirements. Our team supports customers through every stage, from material selection and testing to documentation and delivery. We supply certified elastomers, plastics, and metals that meet global compliance frameworks such as FDA, NSF, WRAS, USP, and NORSOK. Every product is backed by engineering assistance, full traceability, and quality assurance, giving customers the confidence that their seals and components will meet or exceed the most demanding compliance expectations. If you have any questions or require design assistance, feel free to reach out to the Canyon Components engineering team!