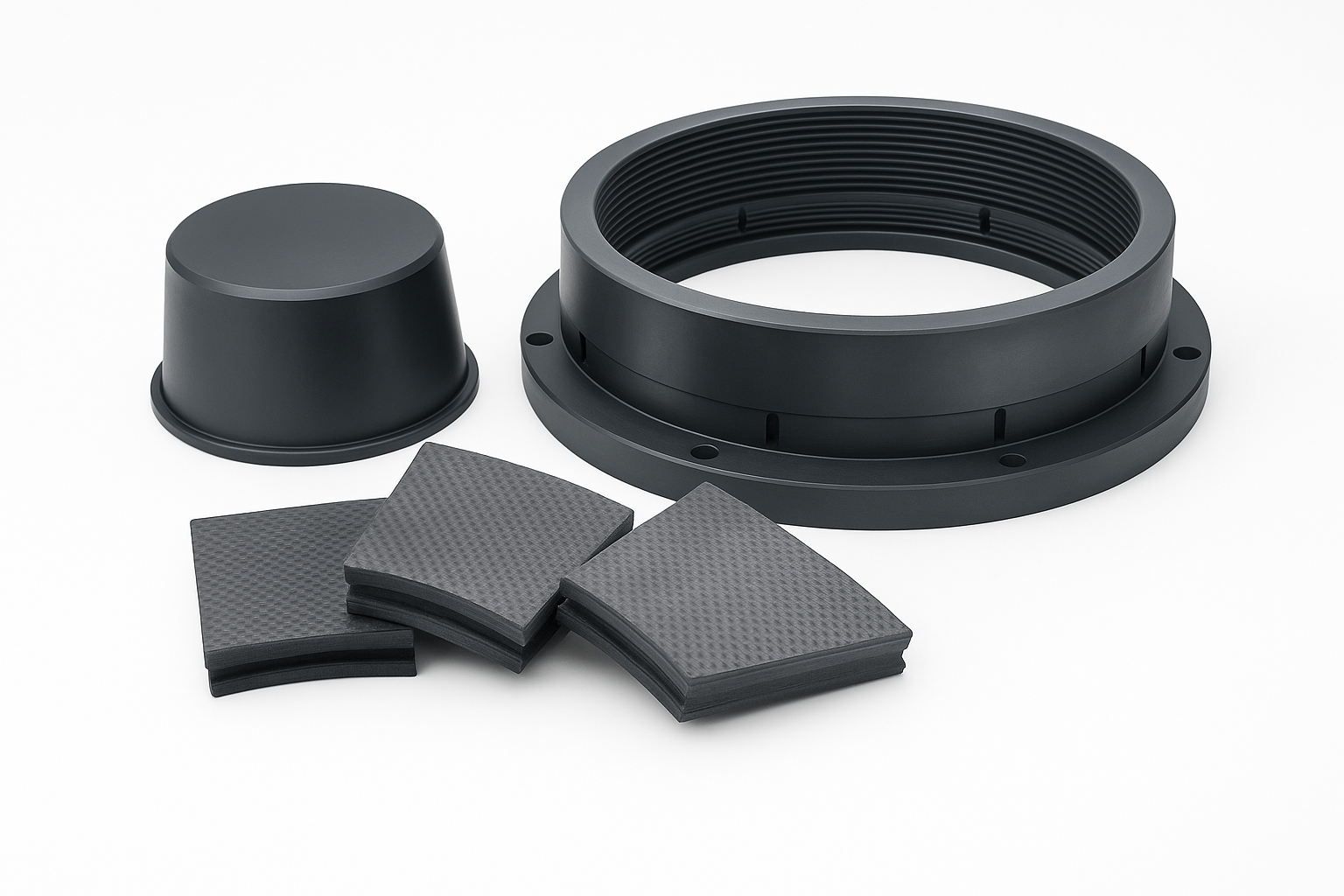

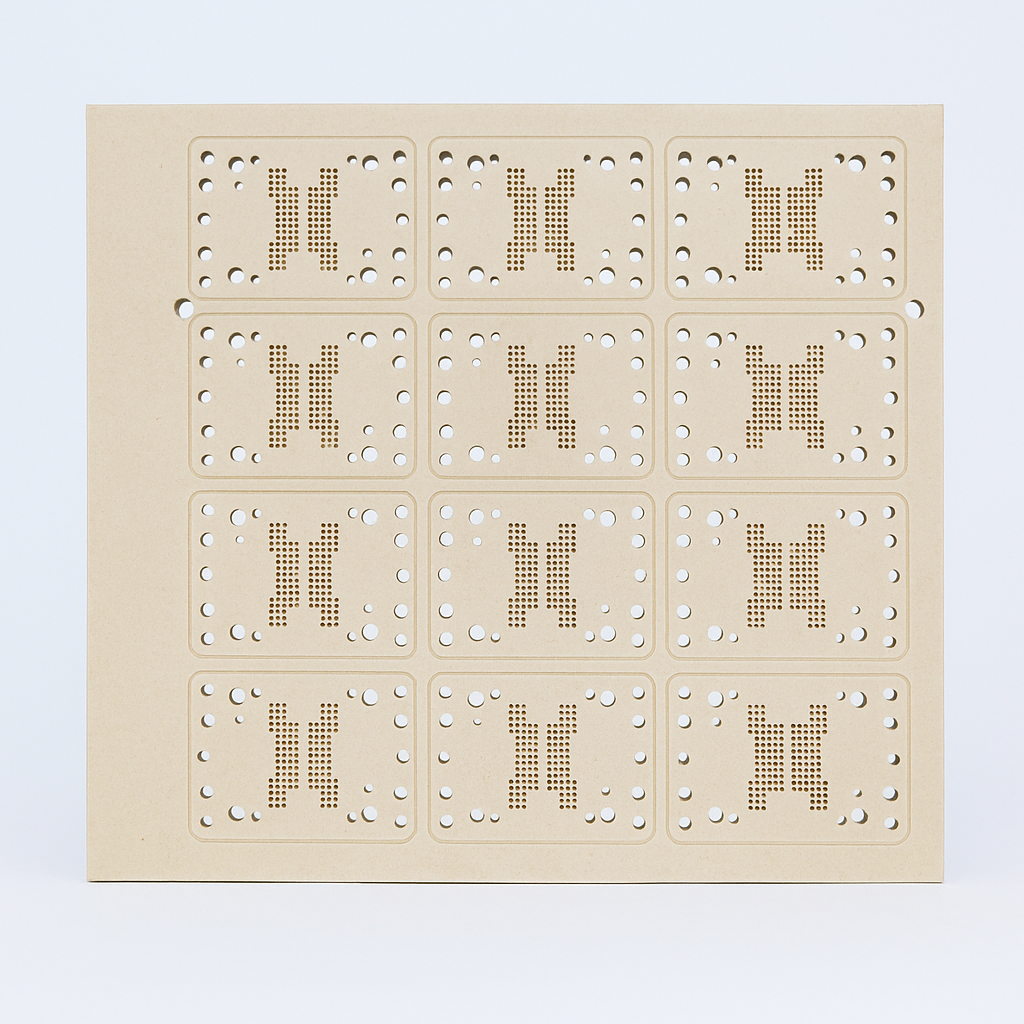

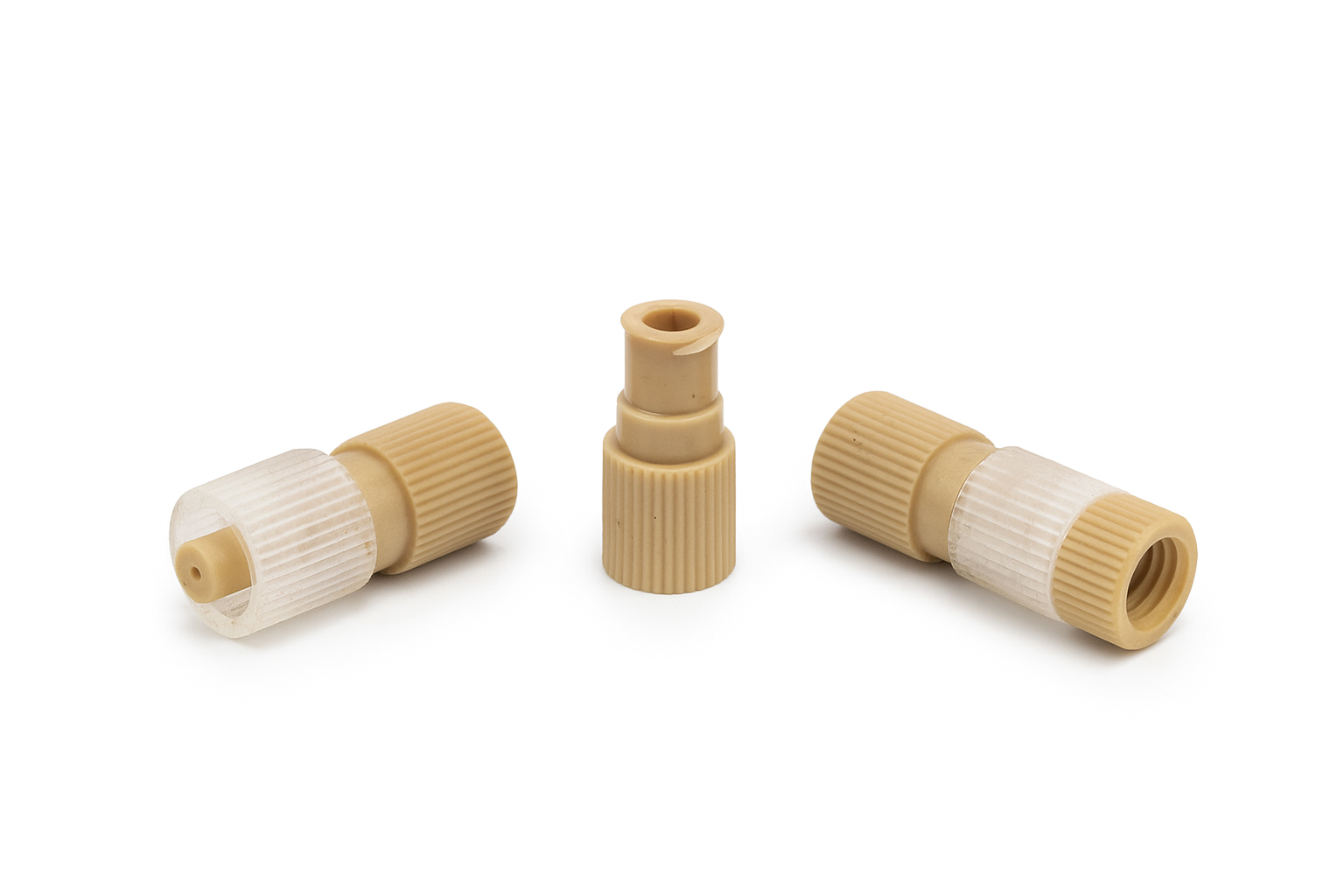

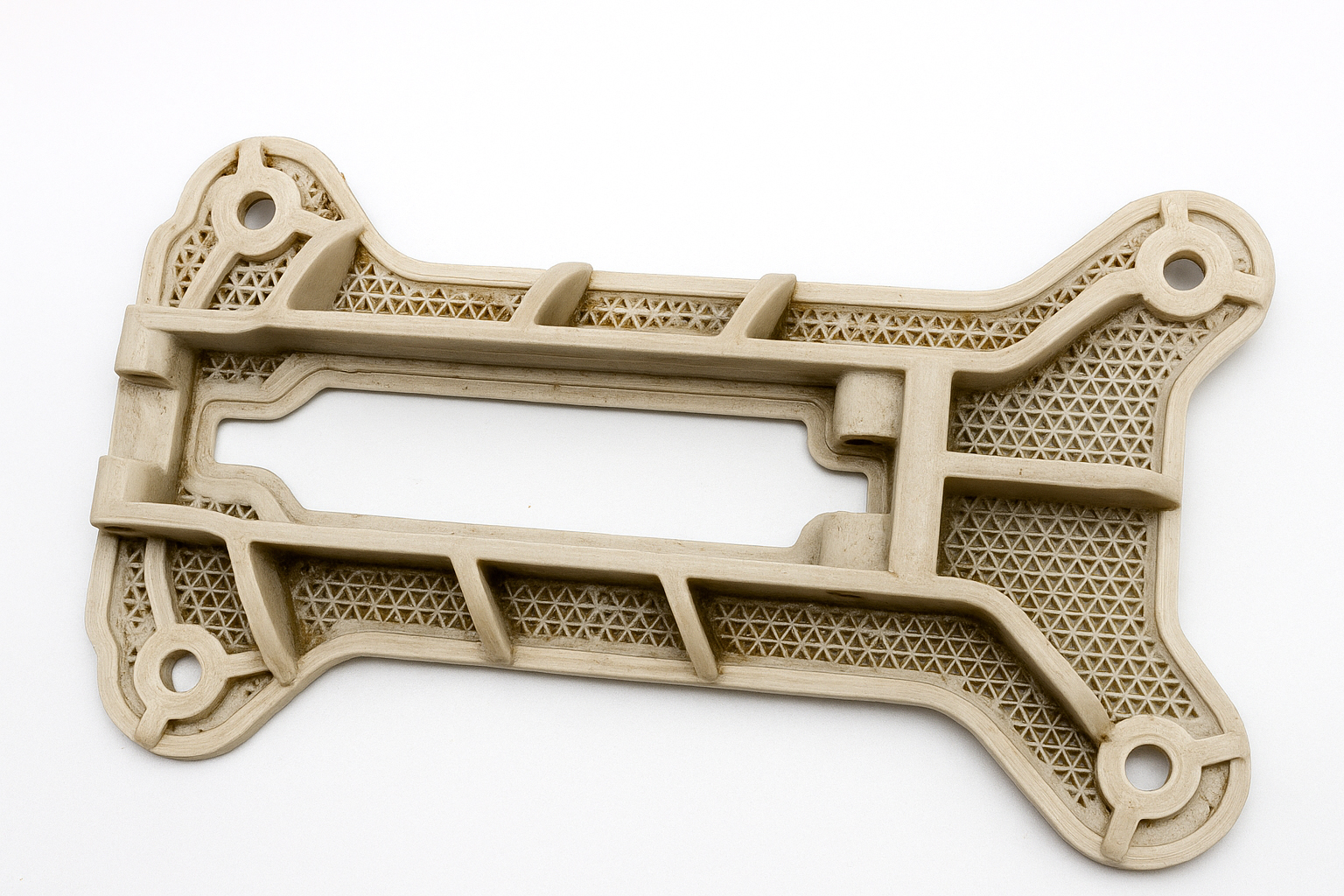

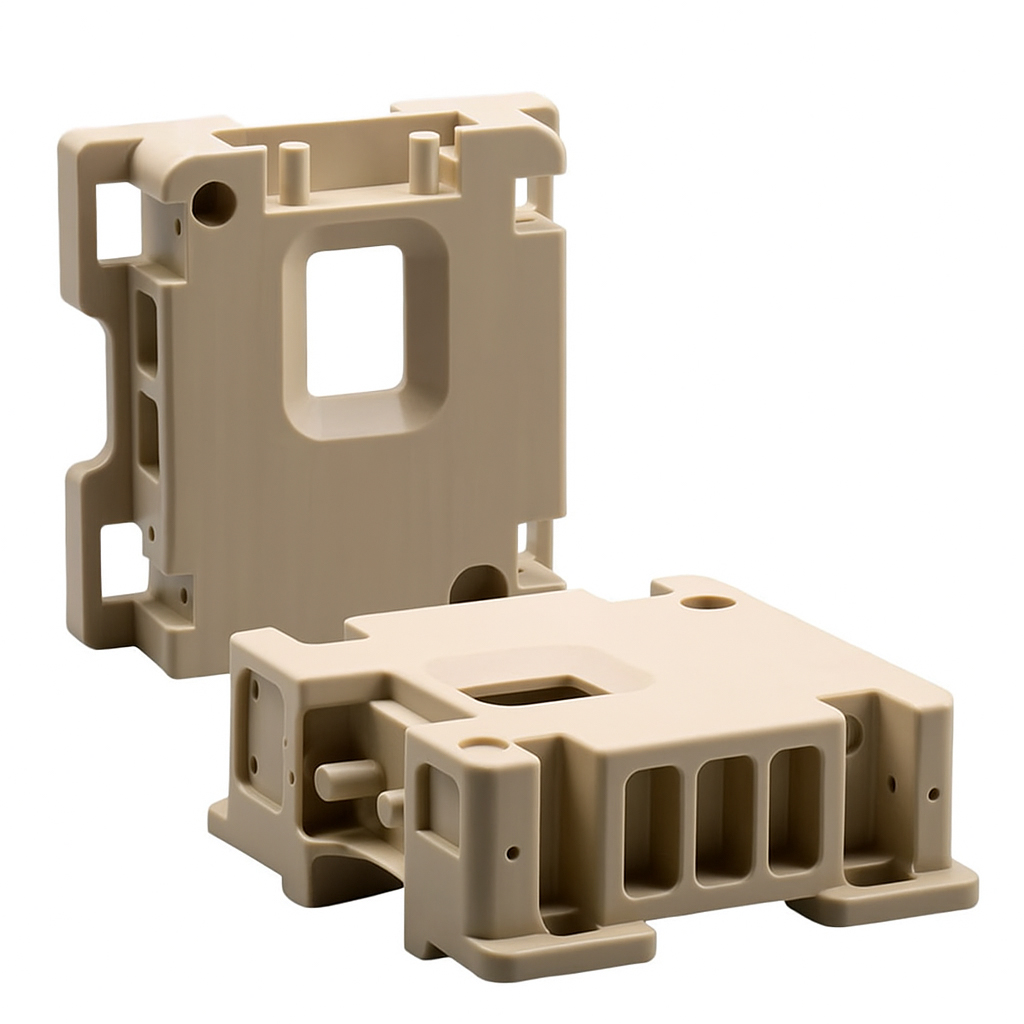

PEEK Custom Parts

Canyon Components provides advanced manufacturing and engineering support for custom PEEK (Polyetheretherketone) parts across a wide range of high-performance industries. Recognized for its exceptional strength-to-weight ratio, thermal stability, and chemical resistance, PEEK is ideal for applications that require mechanical durability, tight tolerances, and long-term reliability in aggressive environments. Our capabilities include CNC machining, injection molding, 3D printing, insert molding, and complex secondary operations—allowing us to handle everything from early-stage prototyping to large-scale production.

Check with one of Canyon’s helpful product engineers for an expert material and manufacturing recommendation.

Keywords: PEEK raw material, high-performance thermoplastic, PEEK plastic resin, PEEK granules, medical-grade PEEK, industrial PEEK polymer, unfilled PEEK, carbon-filled PEEK, bearing-grade PEEK

Why PEEK?

PEEK is a semi-crystalline, high-performance thermoplastic with a melting point around 343°C (649°F). It exhibits high tensile strength, low outgassing, excellent fatigue resistance, low moisture absorption, and inherent flame retardancy. It also maintains dimensional stability across wide temperature ranges and is inherently resistant to radiation, steam sterilization, and most chemicals—including hydrocarbons, acids, and bases.

Canyon Components is your partner in the successful development and manufacture of high-performance custom PEEK parts. Whether you're sourcing components for FDA-compliant medical devices or designing a new solution for aerospace, we deliver the material insight, engineering support, and production precision you need.

Customization Options

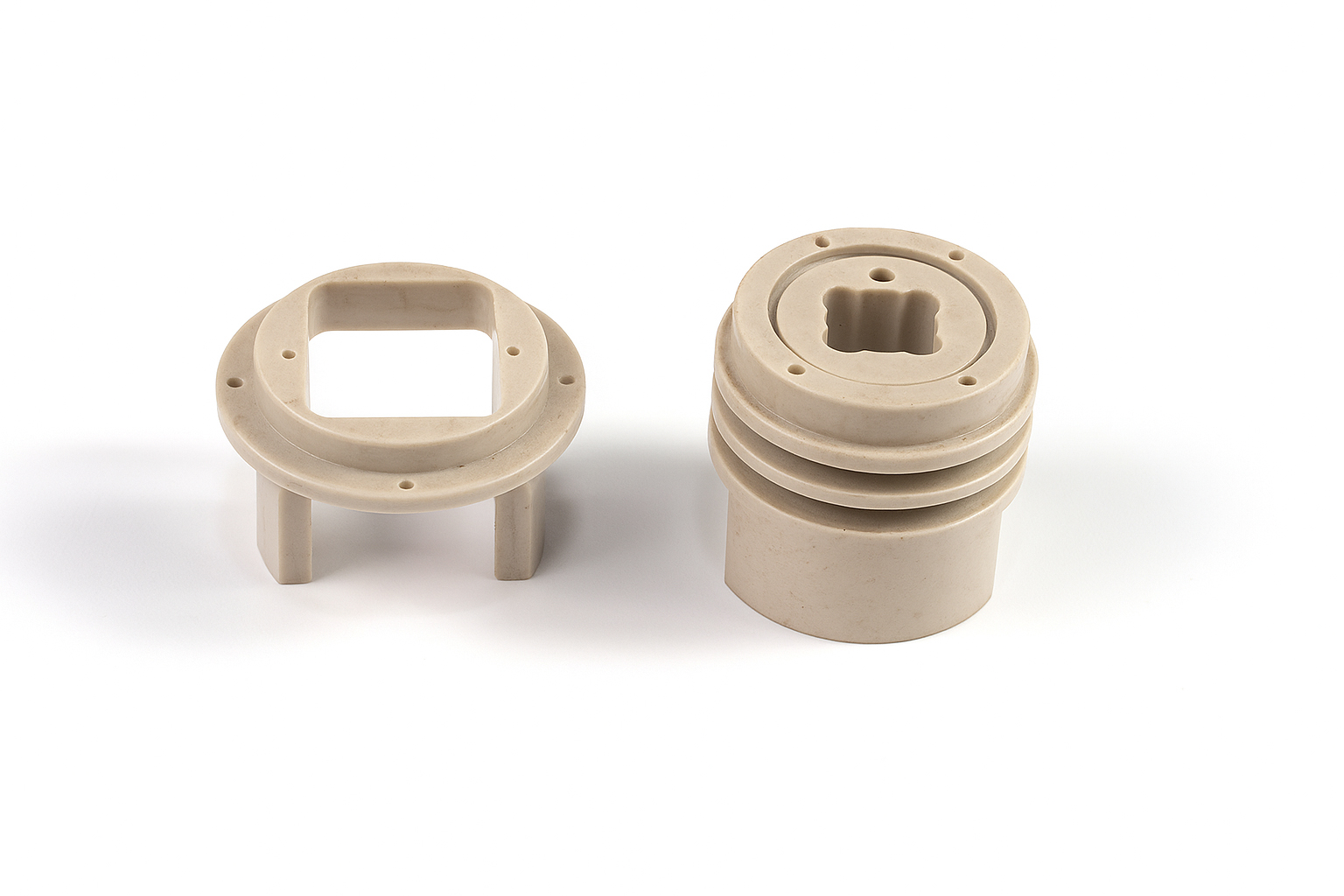

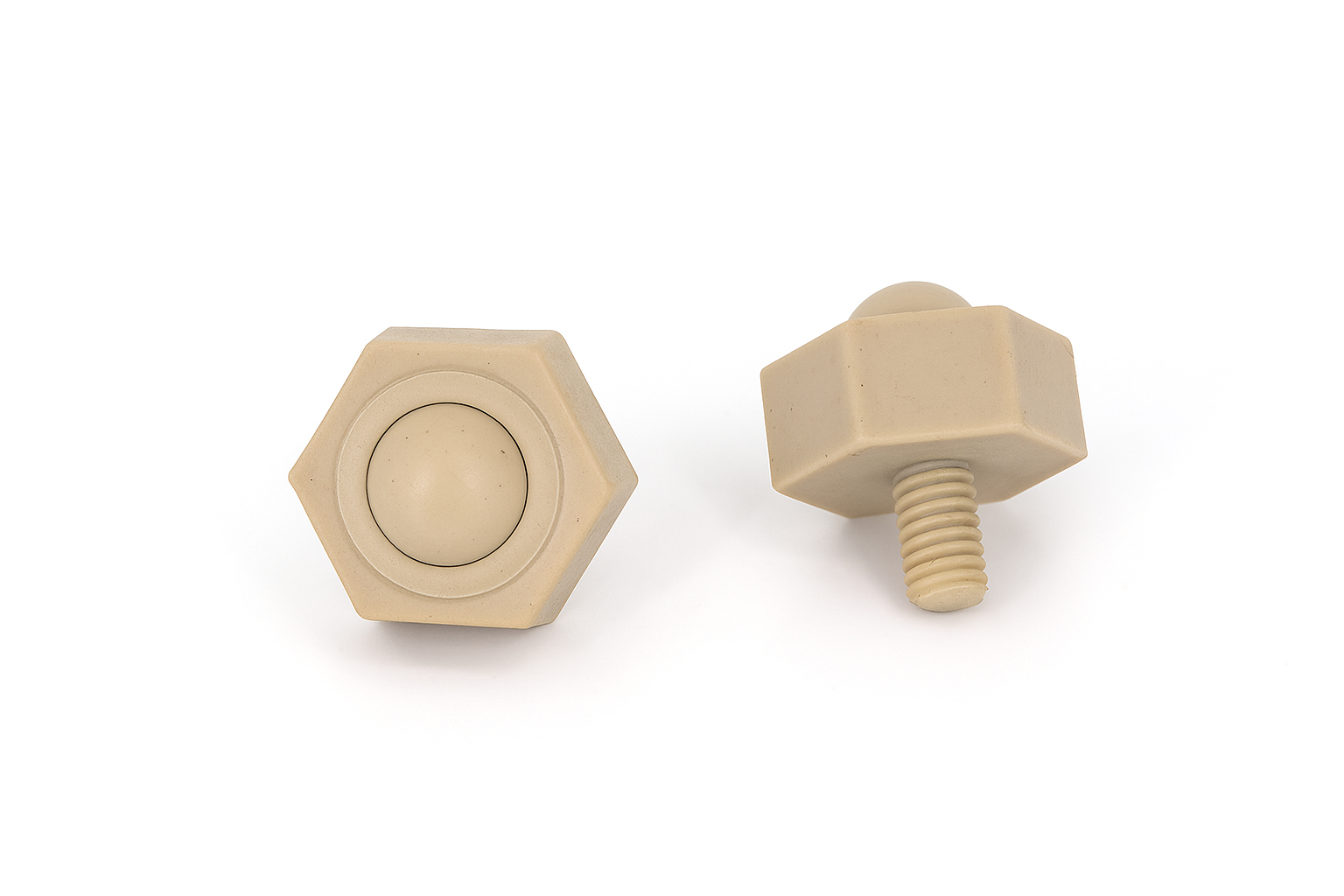

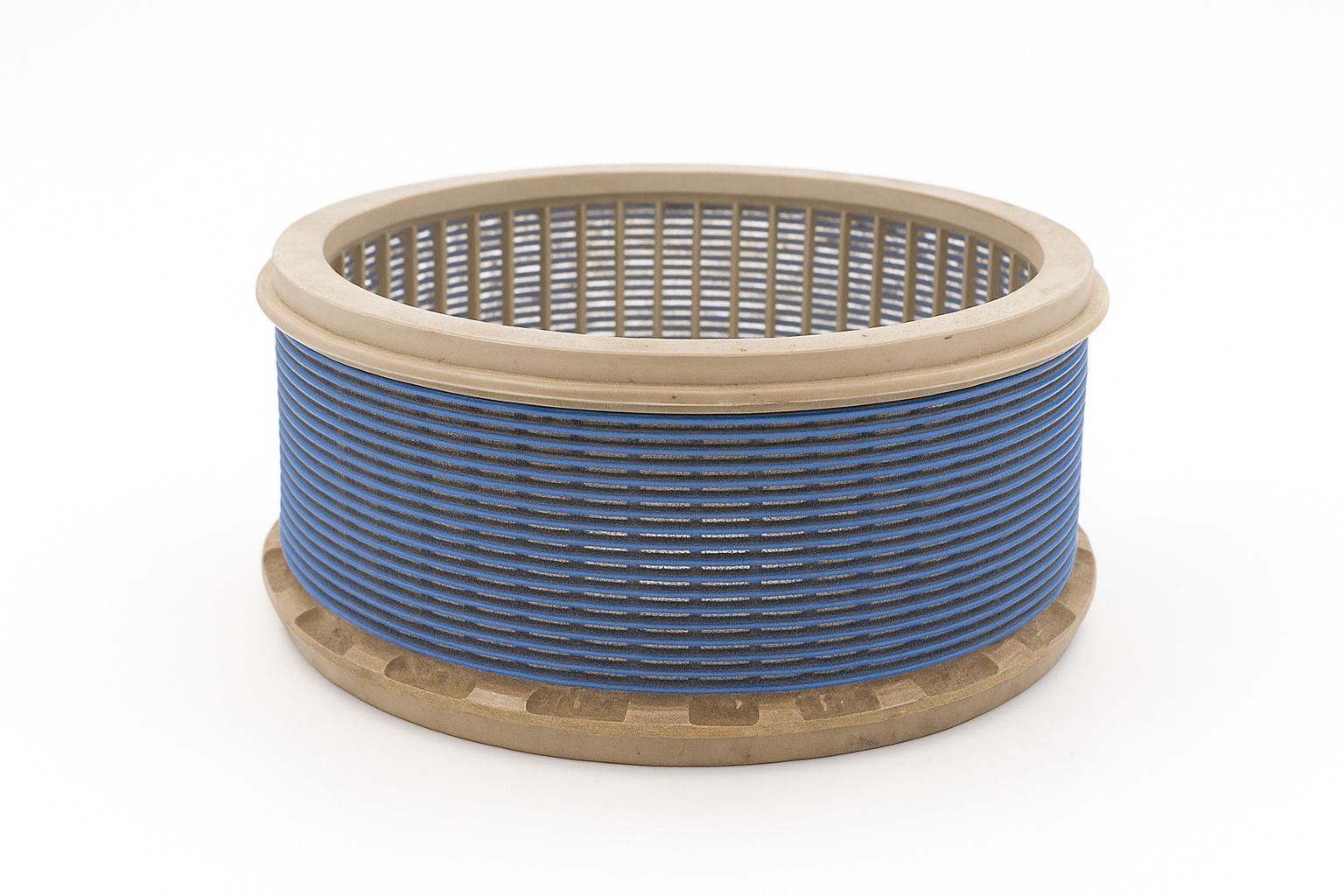

We support a wide range of manufacturing options to meet precise customer requirements:

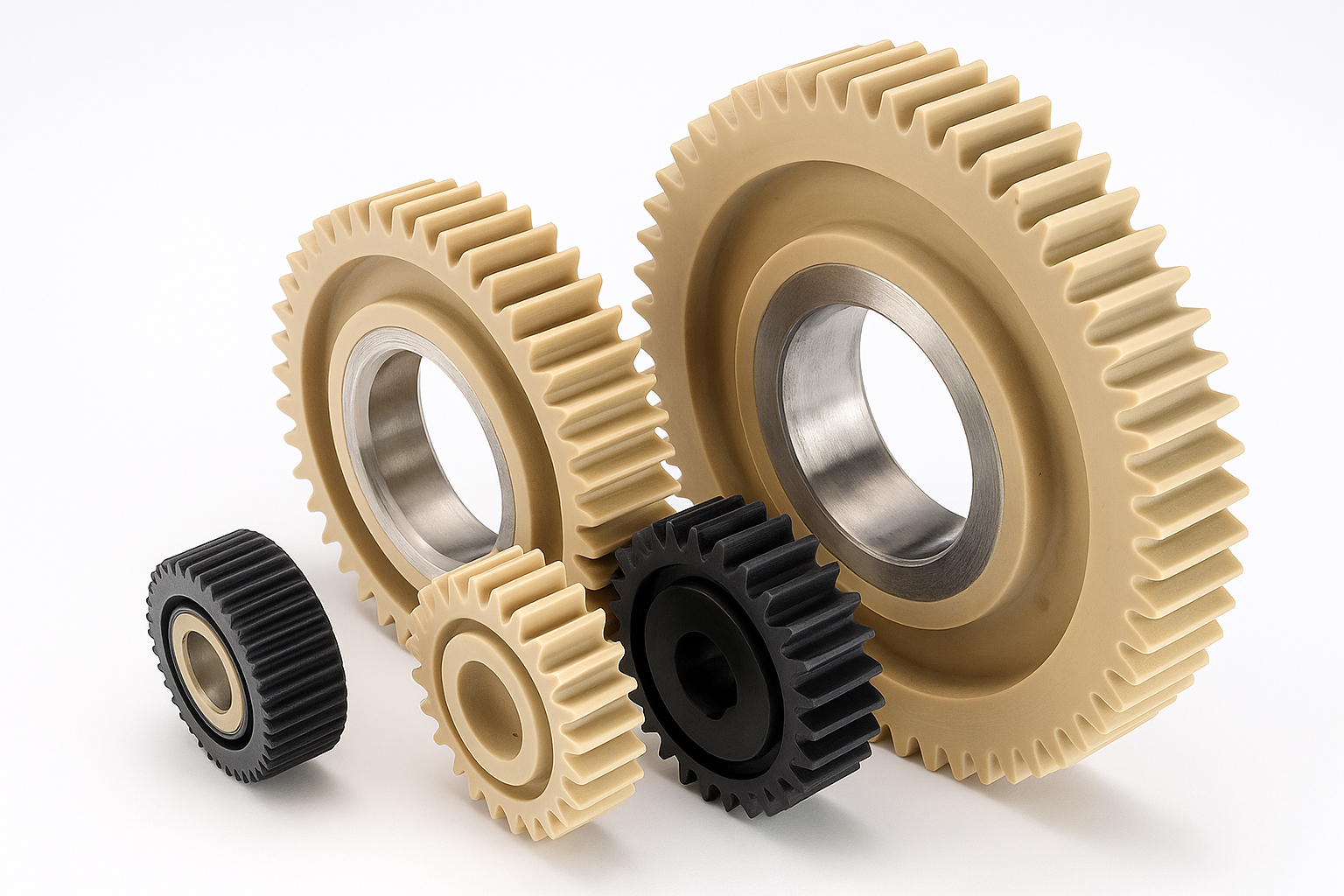

- CNC Machining: High-speed milling, turning, and routing of unfilled and filled PEEK grades to meet precision tolerances.

- Multi-Axis Geometries: 3-axis, 4-axis, and 5-axis machining for complex part designs

- Insert Molding: Combining PEEK with metal or other polymer inserts for hybrid parts

- 3D Printing: High-temp fused filament fabrication (FFF) for rapid prototyping and specialty geometries

- Surface Finishing: Polishing, media blasting, lapping, and sealing for smoother finishes and enhanced performance

- Assembly & Bonding: Ultrasonic welding, adhesive bonding, and mechanical fastening of PEEK to other materials

- Secondary Operations: Threading, engraving, undercuts, sealing features, and chamfers for complete part functionality

We work with all standard and specialty PEEK grades including unfilled, carbon fiber-filled, glass-filled, bearing-grade, and medical-grade PEEK.

Please consult a Canyon Components Engineer about your specific application and we will use our decades of experience to formulate a solution that fits your need.

Get a Quote Now!

Industries Served

Our custom PEEK parts are trusted by clients in:

- Medical & Life Sciences: Implantable components, surgical tools, dental devices, sterilizable enclosures, and Class VI compliant assemblies

- Semiconductor & Photonics: Wafer carriers, IC socket components, electrical insulators, low-particulate handling arms, and vacuum-compatible parts

- Oil & Gas: Downhole sensor components, backup rings, anti-extrusion bushings, and corrosion-resistant valve seats

- Aerospace & Defense: Lightweight aircraft brackets, structural fittings, bushings, seals, and EMI-shielded components

- Energy & Industrial Equipment: Precision gears, rollers, wear pads, electrical isolators, and high-load mechanical parts

Certifications & Traceability

We offer industry-compliant documentation and quality control for sensitive or regulated applications:

- ISO 9001:2015-compliant quality management system

- Traceable Lot Control: Full traceability on material batches used in production

- Certifications Available: FDA 21 CFR 177.2415, USP Class VI, ISO 10993, REACH, RoHS, and EN ISO 13485 compliance where applicable

Why Choose Canyon Components

We offer reliable sourcing of high-quality PEEK raw materials with flexible volume options and short lead times. Our material experts can help you select the right grade and form for your application, whether you're producing PEEK custom parts, PEEK gears and bearings, or high-purity PEEK for medical use.

Canyon Components strives to meet all customer service requests. Feel free to contact Canyon Components engineering and let our knowledgeable staff help you design the perfect part for your needs.

Design & Engineering Support

Whether you have a 3D CAD model, 2D print, or legacy part sample, we offer:

- Design for Manufacturability (DFM): Feedback on how to simplify geometry, improve tolerances, or reduce material waste

- Material Guidance: Recommendations based on chemical, thermal, or mechanical environment; includes FDA/USP Class VI/REACH/RoHS considerations

- Reverse Engineering: We can reproduce discontinued or legacy components with improved performance

- Tolerance & Fit Optimization: Advice on allowances for press fits, thermal expansion, and thin-wall integrity

Advantages of Custom PEEK Parts

- High Precision: Consistent machining tolerances.

- Environmental Resistance: Excellent performance under high temperature, radiation, or chemically aggressive conditions

- Mechanical Strength: Excellent tensile and flexural strength; ideal for load-bearing parts

- Cleanroom & Sterile Ready: Low particulation, low outgassing, and autoclavable

- Reduced Weight vs. Metal: Lightweight replacement for machined titanium or stainless steel in many designs

Back to Plastics Hub

Get A Quote Now!

Groove Design References

Learn More

Coatings, Packaging, & Other Services

Learn More

Custom Parts & Custom O-rings

Learn More